Research in Photography;

A Visit To An Ilford Laboratory

The following article

first appeared in the February 1958 issue of Modern Camera Magazine

(MCM).

A most interesting visit was

paid by the Editor of this magazine recently to the new Ilford

Research Laboratory at Brentwood, Essex, when the technical press

was invited to view the premises a few days before His Royal

Highness the Duke of Edinburgh honoured the company by himself

inspecting what is undoubtedly one of the finest research laboratories

to have been built since the war.

Named the Ramsden Laboratory

after the late Colonel Ramsden, who was closely associated with

the early expansion of the company, it is one of the three principal

Ilford laboratories in this country. The building houses three

sections devoted respectively to physics, chemistry and tests.

The total floor area of 30,000

square feet on two floors is of the most modern construction,

with steel framework encased in concrete. Inside, the wall finish

is polyvinyl chloride fabric applied to the hardwall plaster

and the floors throughout have plastic tiles. In all rooms where

there may be corrosive, or stain-effecting chemicals, the walls

are finished with a special protective paint and in the darkrooms,

where "wet" processes are of special importance, the

floors and walls are lined with asphalt. The laboratory furniture

is designed in units; the tops of benches and the shelving being

cased with melamine plastic; chemical-resisting and easy to clean.

All sinks are lined with rubber and a special drainage system

allows the waste liquids to be treated to recover silver residue.

One of the sections which was

most interesting to visitors was that devoted to emulsions, and

a demonstration was given showing the principles of the preparation

of an emulsion and its final coating on the flexible base. Naturally,

this demonstration, which took place in full light, produced

an emulsion which was worthless photographically because it was

immediately fogged in the demonstration, but yet it gave a good

idea of what happens in practice.

Two separate containers contained

respectively solutions of silver nitrate and ammonium bromide.

These were then together run into a gelatine solution, the mixture

being mechanically stirred, whereupon a yellowish precipitate

of silver bromide was formed. After the addition of a further

small amount of ammonia, the emulsion was warmed to the correct

temperature, which was kept constant for a short period, causing

a growth of the crystals suspended in the gelatine. The custard-like

mixture was subsequently poured into a trough and a band of film

base was continuously coated by passing it over a roller immersed

in the emulsion, which was thus transferred to the base.

In commercial production, of

course, sundry additions of sensitizers and other chemicals are

made and the whole process is carried out in complete darkness.

|

|

Entrance to the New Laboratory

at Brentwood |

|

|

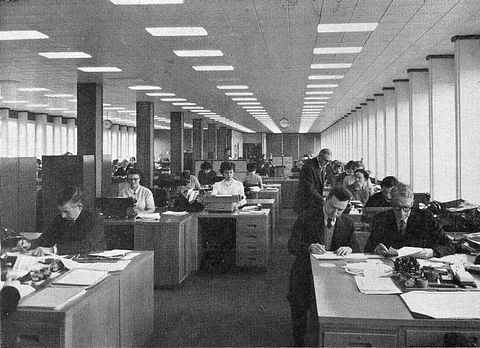

The Whole Building is Temperature-Controlled

and Air-Conditioned |

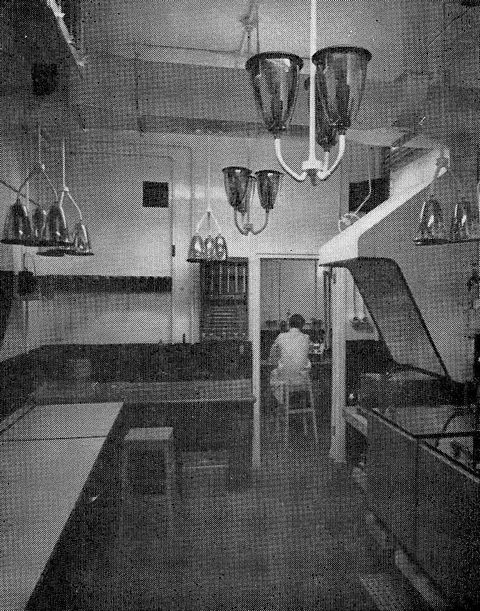

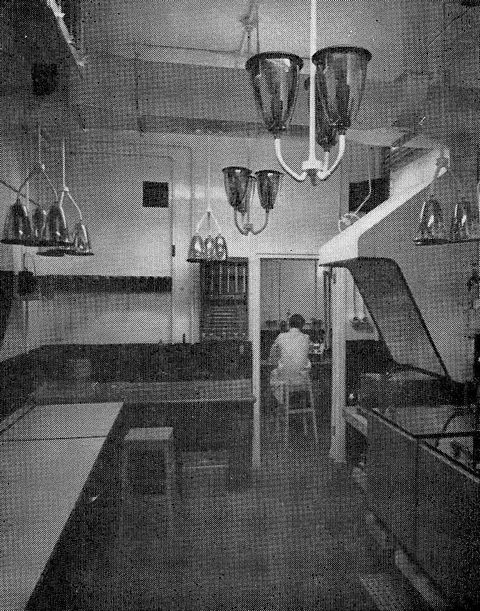

The lighting system in the

darkroom is indirect and can be seen in our illustration (right).

Notice groups of what look like inverted funnels hanging from

the ceiling. These are in sets of three, any one lamp of which

can be switched on according to the work being done. If the sensitivity

of the material being dealt with is affected only by blue light

then the safelight used is amber coloured. If, as with an emulsion

such as Plastika, it is sensitive to both blue and green, the

safelighting is red, while for panchromatic work a very dim green

light can be used.

|

The Indirect Lighting Enables

Three Different Safelights to be Used.

They are Fitted in the Funnel-Like Containers Shown. |

|

|

The physics sections of the

laboratory deal with the three main problems in photographic

material production

Investigation of materials themselves,

Researches in processes such as coating,

Investigations of the special problems in colour photography.

This section includes a drawing

office and a small experimental workshop while, in another part

of the building, a fully equipped engineering workshop with all

the latest machine tools and automatic lathes in charge of skilled

mechanics can produce prototypes of commercial apparatus if needed,

or machines for use in other parts of the laboratory.

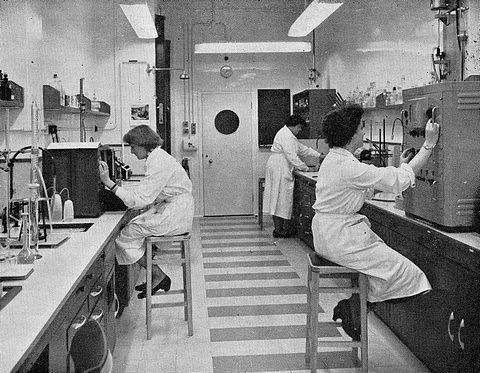

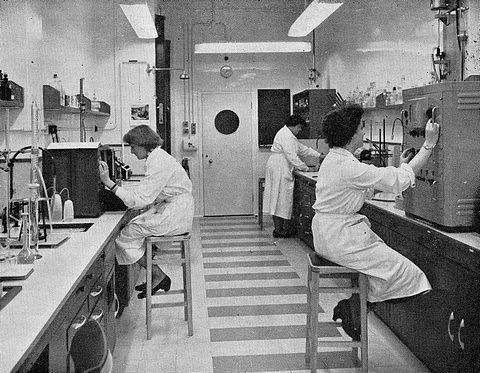

Analysis, of course, plays

a very prominent part in both research and the testing of materials

and we were particularly interested in the use made of the most

modern techniques by means of which, as in colorimetric analysis,

accurate measurement can be made of minute traces of various

substances. Photographic gelatine, for example, is acutely susceptible

to the influences of very small quantities of certain chemicals

and it is only within comparatively recent years that the full

significance of this fact has been appreciated. This is one of

the reasons why the present-day sensitised materials are so reliable

and consistent in their performance.

One of the most important functions

of the laboratory is the preparation of characteristic curves

for the various emulsions being prepared. Step wedge prints are

made under strictly controlled conditions, with automatic sensitometers,

then developed under standardised conditions and the various

densities plotted and subsequently interpreted by a number of

workers. Cleverly designed densitometers enable these curves

to be rapidly plotted in a semi-automatic manner. Incidentally,

in preparing characteristic curves for certain X-ray emulsions,

the step wedge used consists of a number of strips of aluminium

of varying thickness, the thinnest of which is of course completely

opaque to visible light, but transparent to X-rays.

The sensitometry of colour

films is a highly specialised branch of work, to which a great

deal of attention is being given. In the development section

of the laboratory we saw prototypes of new apparatus, which have

been produced to simplify and greatly improve the making of both

duplicate transparencies and the popular Ilfordcolor prints,

which are made from transparencies primarily designed for projection.

A morning spent in these new

research laboratories should convince anyone, in a position to

appreciate the work being done there, that Ilford Limited are

in the forefront of the world's photographic manufacturers, and

have their eye firmly fixed on the future in the development

of the science and art of photography.

|

|

Below are a few photographs dating from around 1964

and provided to me by Terry Brown in January 2020. Terry worked

at the Ramsden Laboratory at the time these photographs were

taken.

The photographs are all of

groups of Terry's colleagues at the Ramsden Laboratory. Many

of these colleagues inter-married and Terry jokingly remarks

that the Ramsden Laboratory was the first marriage bureau in

Brentwood in the 1964/5 era.

Many of the names are known

to Terry but I am witholding them here for their privacy, recognising

that many will still be alive.

|