| A R Pippard; BSc, FRPS, OBE |

|

|

|

|

|

Antony.R.Pippard, O.B.E |

Information on the life and work of A.R. (Antony Russell) Pippard, affectionately known as 'Pip' Pippard, has been sent to me by his son, Jon Pippard, now living with his wife Trish in Sydney, Australia. Sadly, 'Pip' Pippard died very unexpectedly from a stroke aged 66 in 1985. His wife, Doris Elizabeth, lived happily for many further years but passed away on May 4th 2019 after a short illness. She was age 95. |

'Pip' Pippard, by Jon Pippard |

|

|

'Pip' Pippard was born in 1919 in Castle Cary, Somerset. He started a degree in chemistry at Queen Mary College (University of London) in 1939, but was evacuated to Cambridge University due to the outbreak of WW2. 'Pip' amusingly felt this resulted in him being one of the few people to benefit from Mr Hitler's ambitions ! |

|||

|

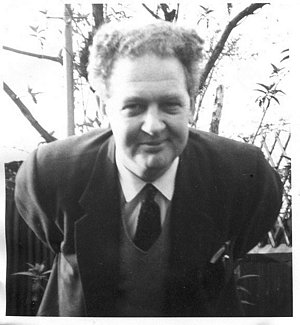

On completion of his BSc degree he worked briefly for a company at Alperton that made starch products, but 'Pip' soon moved to Johnsons, around 1943-44. His first project was to produce improved high definition developers for the purpose of processing photo reconnaisance and X-ray photographs. Jon Pippard believes this work was later applied commercially, to Definol and fine grain developers (Stephen Batey has e-mailed to say he believes 'Pip' was responsible for formulating Johnsons well known 'one shot' Unitol b&w film fine grain developer, introduced inDecember 1950). As 'Pip' was in a protected occupation he did not serve in the WW2 armed forces but he was a proud member of the Home Guard, guarding Hendon Central Station and fire watching. 'Pip' married Doris Elizabeth in 1947, living first in Hampstead and later in Kenton before finally settling at Hatch End, Middlesex. The colour picture (below, far left ~ courtesy of Jon Pippard) shows 'Pip' as a young man in 1947, recently married. The central picture shows Doris, left, with her son Jon and Jon's wife Trish, taken Christmas 2006. The black & white print (right below) shows 'Pip', as photographed by his son Jon using an Ilford Sporti, in 1964. 'Pip' would have been aged 45 and Jon was aged 9. The image is a scan from a 2¼" square contact print. |

|||

|

|

|

|

|

From the early 1950s until the late 1960s he wrote most of Johnsons' instruction leaflets and various publications, amongst them the Johnson Photographic Yearbook and, working with his close friend Kevin MacDonnell, the Johnsons Home Photography series. Such was the sincere friendship between these complimentary characters (Kevin was outward and flambouyant while 'Pip' was happier as the 'backroom boy'), that 'Pip's wife Doris kept in touch with Kevin's daughter, Kieran, for a time after 'Pip's death. |

|||

|

|

The arrival of Ferraniacolor Reversal (transparency) film, 35mm and 120 roll film, into the UK was announced in a Neville Brown & Co. Ltd (NEBRO) full page advertisement within Amateur Photographer magazine dated 5th August 1953. Announced at the same time were the Johnsons of Hendon Ltd home processing kits. Ferraniacolor 20exposure 35mm film cost 15s/3d (76p) and F20 (i.e. 120) roll film cost 12s/3d (61p). The Johnsons home processing kits came in 2 parts, Part 1 - contained the first developer and colour developer - cost 5s (25p) and Part 2 - contained the hardener, bleach and fixer - also cost 5s. In a NEBRO catalogue dated April 1954 there is illustrated a booklet (see left) written by A.R.Pippard B.Sc. entitled "How to Use and Process Ferraniacolor 35mm and Roll Film". It was available free on application. In the same catalogue, 35mm 20exposure Ferraniacolor cassettes cost 15s/3d (76p), 35mm refills cost 11s/10d (59p) and F20 (120) roll films cost 12s/3d (61p). Other roll film sizes were also available. Nebro claimed (at the time) "Ferraniacolor is the only subtractive, integral tripack type of reversal film available with home processsing kits". The speed was officially 25° Scheiner (around 25ASA), though the advise in the booklets shown here (left & below left) was to use 12ASA in all but the brightest of continental sunlight. The booklet shown to the left

was owned by 'Pip' Pippard (hand marked as a 1st Edition) and

was scanned and sent to me by Pip's son, Jon Pippard. |

||

|

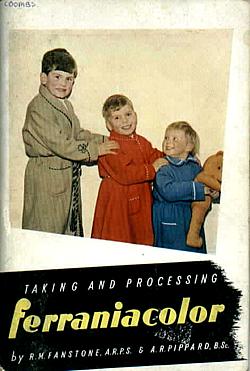

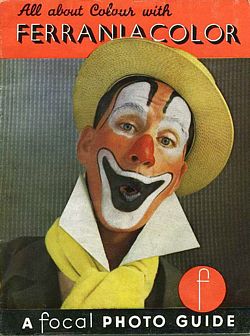

Around 1956 'Pip' co-authored, with R.M.Fanstone, ARPS, another version of the above booklet, see left. This 80 page version was entitled "Taking & Processing Ferraniacolor", and was priced at 4/6d (22.5p). This 1956 booklet appears more substantial than the original (above left), presumably reflecting its cost. Although still based upon the use of the Johnsons Ferraniacolor Processing Kit, it may have been sponsored by Nebro who were Ferraniacolor distributors at the time. This 1956 booklet measures 120mm wide by 180mm tall, and was printed by George Over Ltd of Rugby. To download a pdf file showing some 1960 Ferraniacolor adverts plus a 'Practical Photography' magazine article on processing Ferraniacolor, click here. For information extracted from the Focal Photo Guide entitled "All about Colour with Ferraniacolor", by C.Leslie Thomson (published in 1959) see below. |

|

|

|

The picture alongside, taken by 'Pip' with a Rolleiflex around 1955, was 'shot' on Ferraniacolor. A young Jon Pippard is trying to come to terms with what looks like a screw-topped 35mm Ferrania film canister. The picture would have been taken by 'Pip' with an eye to the possibility of using such a picture to illustrate books such as the ones above and the 'Home Photography' series he co-authored with Kevin MacDonnell. This would explain why he has prominently included some Ferraniacolor packaging in the foreground of Jon's pram. During the 1960s 'Pip' spent time working on the Ferraniacolor colour slide process in Genoa, Italy, and also in Milan. He later did similar for 3M, after 3M took over Ferrania (in June 1964) and acquired the Milan plant. 'Pip' was also responsible for the research production of chemicals for the 'Photo Me' booths, for JPL (Johnson Processing Laboratories). |

|

||

|

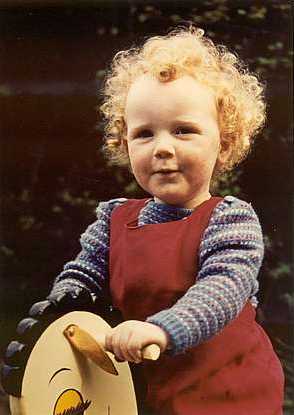

These pictures of Jon Pippard as a toddler, around 1958, were also taken by 'Pip' using a Rolleiflex twin lens reflex (TLR) camera. Both were used to illustrate articles within Johnsons of Hendon publications. Jon believes the picture of him on a wooden rocking horse (made by 'Pip' and called Topsy) was used in a Johnson Photographic Yearbook while the three b&w prints above were used to illustrate print variations possible by using different grades of printing paper (soft, normal & hard) in the 4th Home Photography booklet (c1958) and for several issues thereafter. |

||

|

An August 1959 Organisational Chart for Johnsons of Hendon Technical and Production Staff, supplied by Jon Pippard, can be viewed on my Johnsons of Hendon web page, here. At that time 'Pip' Pippard was already Technical Advisor to the Board and had roles on all (3) Works Committees. Sidney Ray (BSc; MSc; ASIS; HonFBIPP; HonFRPS; FMPA) worked for Johnsons from 1960 to 1966, carrying out R&D, plant supervision, quality control, general photography and technical services. He supplied a detailed history of the Johnson family which you can read here. Amongst his many contributions to photography, Sidney assisted with authoring the year 2000 edition of Focal Press' 'The Manual of Photography' (derived from 'The Ilford Manual of Photography'). 'Pip' worked with Sidney Ray until Sidney left Johnsons in 1966. Then 'Pip' took over the role of Chief Chemist. A major project came along for 'Pip' during the early 1960s when he was made responsible for the design and building of Johnsons new research laboratory, which was completed around 1966. |

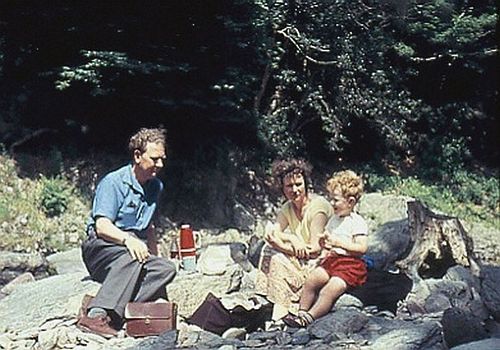

'Pip' and his wife Doris, with Jon, around 1960 |

||

|

Alongside is shown the invitation to the infamous Quaglinos dealer meeting, 27th March 1972, almost immediately after the hostile takeover by Hestair was announced. Jon Pippard says "The top row are the Hestair 'hatchet' men, brought in to asset strip the company, including the pension fund. Not sure about Reuter, or Bigley but suspect they ran the Johnson dealer network". H.Brian Cook, to the left of A.R.Pippard, was the son of Bernard Cook. Brian Cook joined Johnsons in 1951, around the time of Bernard celebrating his 50 years with Johnsons. Brian became a Director around 1958, with responsibility for the construction, maintenance and successful operation of the complex chemical plant at the Hendon factory. Brian had studied chemical engineering at London University and, during the 1950s, had visited an associated company in India where he supervised the installation of a manufacturing plant for photographic chemical products. Jon continues "Dad warned Hestair not to have this meeting because the business model they proposed was unworkable. However, he was, as ever, over ruled. As a result the dealers who did turn up stayed for about 5 minutes and walked out en-masse. Having lost their Hendon site, Johnsons moved to the old Handley Page aircraft factory at Radlett, Hertfordshire, which had closed in 1970. Then, in spring 1974, Johnsons decided to cease photographic chemicals production. 'Pip' lost his job (Christmas 1973?), was rehired but lost his job again (Christmas 1974?) and then couldn't find work, having approached various companies including Ilford, but they had their own problems! By then aged in his 50s, 'Pip' felt he was on the scrapheap and it was a difficult time for him and the family. Fortunately, in 1975 he met up with Adrian Willis (formerly of the Regent Chemical Company), who wanted to re-establish the Johnsons chemicals business. 'Pip' obtained rights to the Johnsons of Hendon 'scales brand' logo, the familiar yellow and orange colour scheme and the famous Johnsons brand names such as Definol etc, but Hestair would not sell the company name 'Johnsons of Hendon'. Hence, 'Pip' and Adrian settled on the name of Photo Technology Ltd and set up operations at Cranbourne Industrial Estate, Potters Bar, Hertfordshire. 'Flask End' was the name of the holding company formed by Adrian Willis of which Photo Technology Ltd was a part. Working within this new venture, and in conjunction with his assistant Malcolm Band, 'Pip' produced the world's first workable '2 bath' process capable of both developing C41 (Kodak process) colour negative film and also EP-2 (Kodak process) colour printing paper processing. The chemistry was named Photocolor II, though much to 'Pip's annoyance, the print developer required a 3rd bottle, a UV brightener, to improve print contrast. Photo Technology Ltd was also responsible for producing Photochrome R, for making positive prints (using Kodak 14RC paper) direct from colour transparencies and later Photocolor Chrome-Six for home processing E6 transparency film. The main competition to Photochrome R was Ilford's Cibachrome A (in 1976) which produced very good results, arguably superior to Photochrome R, but its use could appear daunting because a kit included six chemicals, two being powders, while Photochrome R just required the dilution of liquid concentrates. Photocolor II was featured on Tomorrow's World (around autumn 1976) and 'Pip' was very pleased to attend the recording session, although he was not on TV himself. He was less happy when the presenter, William Woollard, dropped 'Pip's new Konica T3 SLR on the studio floor and bent the lens mount, writing the camera off. Fortunately Olympus provided him with a OM2N in exchange for the insurance money! Although 'Pip' was not always well paid for his efforts (prior to joining with Adrian Willis at Photo Technology), he was eventually rewarded by receiving an OBE from the Queen in 1983 for services to the photo-chemical industry and Jon Pippard reports that 'Pip' felt this was ample recompense for his 40 years of intensive effort. Malcom Band, one of Pip's assistants at Photo Technology Ltd, has emailed to say that ‘Pip’ worked for many years assisting newcomers to the photographic industry, setting exams and invigilating, during the years when apprentices working in Photographic Outlets needed qualifications. For this and other services to photography, ‘Pip’ was awarded the OBE (proposed by Photo Techology's Managing Director, Adrian Willis). ‘Pip’ was very humble about the whole episode. During his latter years 'Pip' gained much enjoyment from taking an interest in amateur photographic competitions and produced several award winning prints, some of which Jon Pippard still possesses. 'Pip' built a home darkroom to enable him to do his own developing & printing of his competition entries. Having stayed at Photo Technology a little past his 65th birthday retirement age (in 1984), 'Pip' died very unexpectedly from a stroke aged 66 in 1985. A more complete history of Photo Technology Ltd, and what happened to it in the years following Pip's death, can be read here. |

|||

|

|

|||

|

Reversal film is processed in what at first seems a complicated way, but the steps are standardized so that careful observance of composition, temperature and times are the principal requirements. The film is first developed in a solution which produces negative silver images in all three emulsion layers. The uppermost image corresponds to the blue of the scene, the middle to the green and the last to the red. The developed film is washed (and, usually, hardened) until all traces of the developer have been cleared. It is then exposed for a few minutes to intense light from a Photoflood bulb. This fogs all the silver salts which were not affected by camera exposure and first development, and renders them developable by the next step. The film looks quite like an ordinary, but unfixed, negative. Colour development produces dyes in each layer; the colour being formed by chemicals already in the layer as manufactured, and the intensity being proportional to the amount of silver produced in this development. Where blue light formed a heavy negative image, for example, there is little remaining salt in the top layer and, in consequence, little yellow dye will be formed. In the other two layers, unaffected by blue light, there will be full concentration of salts: magenta and cyan can be produced strongly and their combined colour is blue. After colour development, the film looks completely opaque, and very little can be made out of the image at this stage. |

|

|

| After a prolonged wash, to remove all traces of the colour developer, the silver is converted into white salts by a bleach bath which at the same time hardens the gelatine. The dyes in the film become more evident now and a kind of image can be seen. The film looks browny-yellow in front and blue-green at the back. Another, brief, wash clears the film enough for the last active bath- fixation. This dissolves out the silver salts, leaving only the dyes in clear gelatine. The finished image is then visible, although its density and colour balance are likely to alter a little as the film dries. | |||

|

Variations in Processing Adequate Re-exposure Incomplete re-exposure shows up as a variation in colour balance across the width of the finished film. There is more magenta along either margin, and this can look very much like stain. In fact the more greenish centre of the film is the truly defective area. |

|||

Footnotes: |

Formulae as officially published in the UK in 1958.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thanks to Stephen Gilmore, I've learned that FILM Ferrania is in the process (mid-2014) of restarting production of analog film in both still and cinema formats. This will be an E6 process transparency film. Click on: http://www.filmferrania.it/ to read more about the announcement and to go 'in-depth' on a very interesting site. | ||

|

|

|

|

|

|

||

'Pip'

Pippard became Technical Director for Johnsons of Hendon in 1970

but by 1972 the company had been acquired by Hestair who asset

stripped by selling the Hendon site, which was worth a lot of

money and subsequently became the Brent Cross shopping centre.

In consequence, the 'new' (in 1966) Johnsons laboratory is now,

unfortunately, under the car park of the Brent Cross shopping

complex !

'Pip'

Pippard became Technical Director for Johnsons of Hendon in 1970

but by 1972 the company had been acquired by Hestair who asset

stripped by selling the Hendon site, which was worth a lot of

money and subsequently became the Brent Cross shopping centre.

In consequence, the 'new' (in 1966) Johnsons laboratory is now,

unfortunately, under the car park of the Brent Cross shopping

complex !