| Paterson 'Acu' Monochrome Chemistry |

|

|

|

|

|

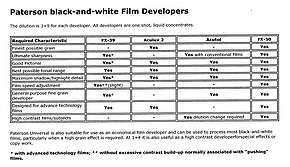

The

table below tries to show the approximate chronology of the Paterson

'Acu' range of developers. Information on other 'Acu' products, not developers, can be viewed here. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|||||||||||

|

Initially just named Acuprint, it reverted to this by Autumn 1998 |

|||||||||||

|

|

|||||||||||

|

|

|

||||||||||

|

|

|||||||||||

|

|

|

(new formulation) |

|||||||||

|

|

|

||||||||||

|

Just Pro-Print in 1984; Phototec Scales Brand in 1998 |

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

The

name of Paterson still exists in the world of photographic equipment

supply and they can be contacted at: The

name of Paterson still exists in the world of photographic equipment

supply and they can be contacted at:Paterson Photographic Limited, 2 Malthouse Road, Tipton, West Midlands, UK. DY4 9AE. Telephone: 0121 520 4830 Fax: 0121 520 4831; Email: sales@patersonphotog.plus.com. They still offer a wide range of photographic darkroom products. |

|||||||||||||||||||||

|

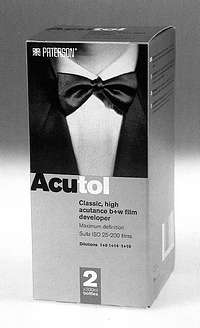

Paterson introduced its own comprehensive range of black & white chemistry, starting with Acutol, a fine grain, high acutance, developer in autumn 1963 (Amateur Photographer reviewed it in their 30th October 1963 issue). It was invented by Geoffrey.W Crawley (see his picture, left) Sold in screw-capped 220cc

(7.5 fluid ounce) metal cans, requiring to be diluted 1:6. Acutol was made more concentrated, packaged in 170cc (6 fluid ounce) glass bottles and re-named Acutol FX 14 in early June 1964 (ref: AP 10th June, What's New?). Its standard dilution changed from 1:6 to 1:10 and the bottles incorporated a sealing washer to ensure efficient re-sealing after being opened. This was to counter adverse claims of the original's poor keeping properties. Price remained unchanged at 4s (25p) even though the greater concentration gave 25% more working solution. |

||||||||||||||||||||

|

|

|

|

|||||||||||||||||||

|

|||||||||||||||||||||

| PATERSON ACUTOL-S (FX-15) SOLVENT TYPE DEVELOPER (FX-15 is the short tin in the Amateur Photographer advert, below) | |||

|

|||

|

* Fine grain An Amateur Photographer magazine test of Acutol S, dated 22nd January 1964, can be downloaded as a pdf file here. FX15 Acutol S, according to this website, has the ingedients: |

|||

|

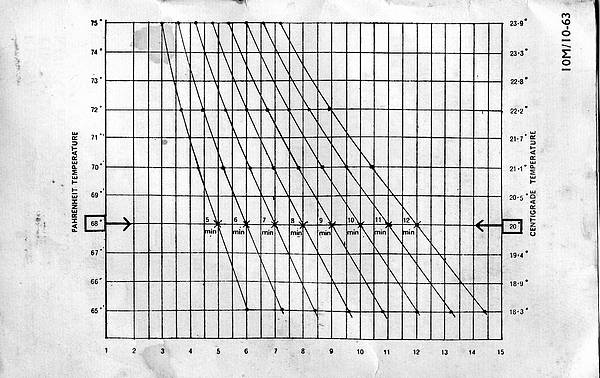

ACUTOL

FX-14 DEVELOPER |

| A July 1991 instruction leaflet for Paterson Acutol FX-14, giving development times for dilutions of 1:10, 1:15 and 1:20 can be viewed here. | |

|

ACUSPEED FX-20 DEVELOPER

(see development times above) A July 1991 instruction leaflet for Paterson Acuspeed FX-20 at dilution 1:7 can be viewed here. |

|

|

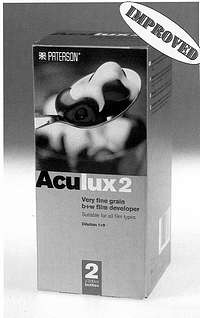

ACULUX FX-24 DEVELOPER (see

development times above) A July 1991 instruction leaflet for Paterson Aculux FX-24, can be viewed here. |

|

| UNIVERSAL FX-26

DEVELOPER Universal developer is suitable both for films and for papers. It is ideal for circumstances where the economy of one bottle of developer is helpful, such as for example, to a beginner. Negatives developed in Universal will be crisp in detail, bright in contrast and with low fog level. They will print easily to show a wide range of tones. The dilution for films is 1 + 19, making it very economical. For prints, Universal Developer is diluted 1 + 7, It gives rich blacks, pure base whiteness and a good range of middle tones with a neutral image colour. To make a rapid-acting Press-type developer, Universal can be diluted 1 +4. At this dilution it is also useful as a high contrast developer for copying or other special darkroom effects on film or paper where a normal film or print developer would be too soft-working. Standard dilution for films: 1 + 19 and for papers: 1 + 7. To view instructions as supplied with the bottle of concentrate FX-26, see below (courtesy of Luca Liverani). |

|

|

|

|

| PATERSON UNIVERSAL

DEVELOPER: FX-26; Warning;

this developer is an alkaline solution. Avoid contact with the

eyes. Prolonged contact with the skin can cause irritation. Characteristics Universal DEVELOPER PATERSON FX-26 is suitable for processing films and papers. Its concentrated liquid formula allows great economy of use. It produces bright and clear negatives with minimal fog and with increased exposure latitude. With paper, it gives a rich range of tones, from pure white to deep black. Exposure of Films Film sensitivity is as indicated by the manufacturer. Dilution for Film Development Prepare the solution for use by diluting 1 part of concentrated developer in 19 parts water. To calculate the amount of concentrate to use, divide by 20 the amount of developer required by the film developing tank. For example: to achieve 300cc, use 15cc of liquid concentrate. Discard the diluted developer after use. Dilution for Printing Paper Development Dilute 1 part concentrate developer to 7 parts water. Discard the solution when it turns yellow. Storage and Conservation Qualities Universal DEVELOPER FX-26 should be kept under cool (but not refrigerated) conditions, which will enable many months of storage without oxidation. The developer concentrate should not be used once it has oxidised beyond a dark straw colour; its properties will then being seriously affected. If part of the concentrate requires to be stored for several months, the risk of deterioration can be reduced by transferring it to a smaller bottle that is filled completely and closed tightly. Development Time for Films Use the development times shown in the table included on the bottle label. Development Time for Printing Papers The normal processing time is 1½ to 2 minutes at a temperature of 20°C. With plastic coated RC type papers the image appears faster and the development time can be reduced by 20%. Film Development Agitation To obtain consistent results agitation must be standardised. Agitation may be by either of two methods: by tank inversion or by rotating the spiral within the tank. Development times given in the graph are for inversion agitation every minute using a Paterson developing tank (any model) or by rotating the spiral for 5 sec every minute. The recommended method is by inversion agitation. The procedure is as follows: 1 Pour the developer into the tank and rotate the spiral quickly in order to eliminate any air bubbles. Then leave the tank for a minute. 2 Invert the tank every minute, immediately returning it to its upright position. If agitation is continuous, development times can be reduced by 20%. After Treatment The use of liquid Paterson Acustop is recommended. It is provided with an exhaustion indicator and immediately stops development and prolongs the life of the fixer. FX-26 and Acustop can be used with any fixer or fixer hardener. However, use of Paterson Acufix is especially recommended as it ensures rapid fixing, has a long life, gives maximum quality of negatives and prints that require a minimum washing time. High Dilutions To increase the control of development, it is possible to dilute FX-26 in the ratio 1+29 in conjunction with a 50% increased development time;.This procedure is particularly recommended for high processing temperatures. Kodak VP 110 film is best developed using Paterson Acuspecial developer, but FX-26 can be used if diluted 1+29, developing for 5½ minutes at a temperature of 20°C. Time Saving Diluting FX-26 concentrate 1+4 allows rapid development of prints in approximately 45 to 60 seconds. At this dilution it is especially suitable for use with microfilm or graphic art surfaces, producing high contrast effects. Temperature Variation Development times vary, depending on the temperature being above or below 20°C. Use the following instructions in conjunction with the graph (see above) for determining Time / Temperature variations. To use the graph, firstly determine from the 'Development Times' table (above), the development time in minutes at 20°C corresponding to your specific film. Find that development time along the horizontal minutes axis of the graph and follow that line vertically upwards to where it intersects with the horizontal 20°C line (68°F). Then follow the curve passing through the 20°C line to the actual temperature of your developer and determine the revised development time by reading vertically downwards to the minutes axis. In the case of a recommended 20°C development time that is not a whole number of minutes e.g. 4½ minutes, follow a curve between the two adjacent ones for 4minutes and 5 minutes. |

|

|

ACUTEC

FX-35 DEVELOPER (see development times above) Acutec has been specially designed for use with continuous tone, general purpose films of speeds of up to ISO 200 and with high contrast, copy films. It is a highly concentrated liquid developer and is supplied in the form of TWO solutions. This ensures a long shelf life, even in part empty bottles. When developed in Acutec, high contrast copy films now widely being used for general photographic and pictorial purposes will not exceed a certain limit of maximum density, however over-exposed the negative or high the subject contrast. With all films, Acutec provides somewhat finer grain and better retention of micro-detail, by adopting a different chemical approach. These benefits are at their maximum in the case of high contrast copy films, such as Kodak Technical Pan 2415, Agfaortho 25, etc., possessing extremely fine grain and high resolving power. These films, which now find an increasingly wide use, pose the problem of controlling contrast, and at the same time preserving good separation of tones across the range from deep shadows to highlights. Acutec provides the complete answer to this problem, ensuring at the same time the highest standard of micro-detail resolution. Exposure accuracy is more than usually important in the case of copy films in view of their virtual lack of under-exposure latitude. Cameras with built-in exposure systems should be set to the manufacturer's recommended film speed setting as a starting point. If readings are taken from shadow areas, however, film speed settings may, with experience, be increased by one-third to two-thirds of a stop. With general purpose films a gain in film speed of a full two-thirds stop is attained. The developer is supplied in two 100ml bottles, sufficient to process ten 135-36 films. |

|

|

ACUPRINT FX-17 PRINT DEVELOPER A 1981 Paterson Acuprint FX-17 instruction leaflet can be viewed here, together with an instruction leaflet for the same chemistry in November 1998. A further leaflet, this one dating to 1985, can be downloaded as a pdf file here. |

||

|

Paterson's brochure for 1973 / 1974 shows no new additions to the range, though some of the packaging has changed. Back row; Acufix (medium),

Acustop, Acutol, Acuprint, Acuspeed. FX-18 Developer. A standard P.Q. Borax developer conferring advantages when used instead of the more conventional M.Q. Borax developers. A single powder for rapid preparation. Gives full emulsion speed, fine grain, good image sharpness and has a long working life. |

| Paterson's brochure 'Darkroom Equipment' for August 1984 shows six developers, two are new, while two previous ones (those supplied as powders; Acutol-S FX-15 and FX-18) are no longer available. All chemicals are now supplied as liquid concentrates in plastic bottles. | |

|

There is a new 'Pro' range, called Pro-Print and Pro-Fix, in 2.5litre and 5litre containers only. PRO-PRINT DEVELOPER FX-34

The Scales Brand trademark suggests it may have originally been part of the Johnsons of Hendon formulas purchased by Photo Technology Ltd in 1976. |

|

|

A 1981 Paterson Acuprint FX-17 instruction leaflet can be viewed here, together with an instruction leaflet for the same chemistry in November 1998. A July 1991 instruction leaflet for Paterson Aculux FX-24, Acuspeed FX-20, Acutol FX-14 and Universal FX-26 can be viewed here. |

|

|

All developer dilutions have been standardised to 1 part concentrate to 9 parts water. |

||

|

|

|

||

|

|

|

|

Aculux 2 can be used for all black and white

films, regardless of speed or grain group. It is a one shot,

fine grain developer, now reformulated to give a more compact

grain structure, even better tonal gradation and improved highlight

and shadow detail. When used with modern hi-tech films such as

Paterson Acupan 200 it will produce almost grain-free negative

of exceptional quality.

|

Acutol is a medium fine grain, high acutance developer.

Acutance is the term used to describe sharpness of the image

- particularly the edges of fine detail. The 'edge effect' of

Acutol is most marked on slow, fine, conventional grain films

up to ISO 125. As these are usually of high contrast, the compensating

effect available with Acutol is also beneficial.

|

FX-39 is a one-shot high definition developer designed

to allow a new standard of sharpness and definition to be reached.

It has been designed to exploit the properties of films using

advanced silver halide grain technology such as those in the

Paterson Acupan Kodak T-Max, Ilford Delta, Agfa APX and Fuji

ranges.

|

|

|

||

|

|

|

|

Varispeed makes the most of the faster, modern

B+W films, including their ability to be "push processed".

|

Universal developer is suitable for both films

and papers can be very economical for the beginner or those on

a budget.

|

P-Tec Unitol Fine-Grain developer

|

|

|

||

|

|

or click on the small images to the left and below. Dilution is 1 part concentrate to 9 parts water for all developers.  |

|

An instruction leaflet for

Acufix, packaged by the Paterson Photax Group during the early

1990s, can be viewed here. |

||

|

||

|

|

||

|

||

|

|

|

|

|

|

||

By

1998, Pro-Print is one of Paterson's economy range Phototec

Scales Brand, and the bottle (1litre and 3litres) bears the

simple name 'Rapid Print Developer'.

By

1998, Pro-Print is one of Paterson's economy range Phototec

Scales Brand, and the bottle (1litre and 3litres) bears the

simple name 'Rapid Print Developer'.

It was the subject of a Mini Test by

William Cheung:

It was the subject of a Mini Test by

William Cheung:

ACUFIX

is a rapid acting fixer for all films and papers, based on ammonium

thiosulphate as the fixing agent.

ACUFIX

is a rapid acting fixer for all films and papers, based on ammonium

thiosulphate as the fixing agent.