|

|

|

|

|

|

all of them being Fluidised Bed Combustion (FBC) equipment manufacturers. |

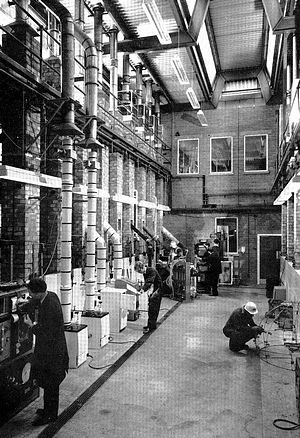

_MFmod.jpg) In the background is the CRE Exhibition Hall and behind that are the chimneys of the Test Boiler House |

|

CRE Formation For 50 years, until the end of 1997, CRE was based at Stoke Orchard, a village to the north-west of Cheltenham in Gloucestershire, England. Stoke Orchard is in the borough of Tewkesbury and neighbours Elmstone-Hardwicke, Tredington and Bishop's Cleeve. Colleagues always referred to Stoke Orchard as being near Bishop's Cleeve. For much of its existence, its postal address and other contact details were: Coal Research Establishment, The National Archives, at Kew, have a website which describes how, after the National Coal Board was formed, on 1st January 1947, the functions and records of the Powell Duffryn Research Laboratory (previously within the South Wales mining company called Powell Duffryn Associated Collieries, but within the NCB from 1947) became the basis of the Research Establishment which eventually became known as the Coal Research Establishment (CRE). |

||

|

|

The Kew Archives contain CRE Annual Reports going back to 1st January 1949, though that first Report also includes comment from the earliest time of CRE's existence, 1st April 1948. Six such Reports cover dates to 31st December 1954 that are entitled "National Coal Board, Scientific Department, Central Research Establishment Annual Report". The 7th report, covering 1st January to 31st December 1955, is entitled "National Coal Board, Scientific Department, Coal Research Establishment Annual Report", confirming that CRE, as the Coal Research Establishment, came into existence during 1955. The National Coal Board (NCB) was the statutory corporation created to run the nationalised coal mining industry in the United Kingdom. It was set up by Clement Attlee's post-war Labour government under the Coal Industry Nationalisation Act 1946, and it took over the mines on "vesting day", being 1st January 1947. In 1987 the NCB was renamed the British Coal Corporation (BCC), and its assets were subsequently (by 1994) privatised. Lord Hyndley, Chairman of the National Coal Board, inspected the Board's newly opened Central Research Establishment at Stoke Orchard, Cheltenham, on 24th April 1950 (ref: newspaper archives; Dundee Evening Telegraph). |

|

|

Wikipedia tells us that the Stoke Orchard site was previously a Ministry for Aircraft Production shadow factory run by the Gloster Aircraft Company adjacent to RAF Stoke Orchard. A shadow factory was a factory set up to emulate the manufacturing capabilities of a parent organisation, such that production could continue in the event of the parent company suffering war damage. Martyn Davis, an ex-CRE colleague, tells me that his father-in-law was born and lived in Stoke Orchard village and had told him that "the Gloster Aircraft Company occupied it during the war (WW2) and they made engines there. They were tested in the site's out-buildings before being taken to the adjacent RAF Stoke Orchard, where completed aircraft took off from the airfield across the road, by the refuse tip" (now run by Grundon Waste Management at Wingmoor Farm, Stoke Orchard Road, Bishops Cleeve, GL52 7DG). The Stoke Orchard and Tredington Parish Plan, October 2009, reveals that RAF Stoke Orchard became a base preparing for D-Day (6th June 1944) at which pilots were trained to tow the transport gliders which would carry the troops and equipment over the channel for the Normandy landings. After the D-Day landings the RAF left and WarAg (the War Agricultural Committee) took over the hangars as an implement depot and repair centre for their agricultural equipment, used for improving unproductive land. Martyn understands that the CRE site was acquired by the NCB from Roy Fedden (since confirmed; Ref: Introduction to the 1949 CRE Annual Report) who had the site after the Gloster Aircraft Company and where he made a prototype automobile, but it did not get into production. It was powered by a three-cylinder air-cooled radial engine that had vibration and overheating problems. Also the car tended to skid badly when being cornered hard. Work started on a replacement chassis, but the rest of the company's engineers lost interest and left, and soon the company had to be dissolved. After this, Fedden worked for a time consulting with George Dowty, but soon retired and spent his time teaching at the College of Aeronautics at Cranfield University. The site was acquired from Roy Fedden by the National Coal Board's Scientific Department (Headquarters) on 1st April 1948. Thence, preparatory work was carried out in equipping and modifying the site's buildings to house a small research staff from South Wales and London. This staff were transferred to CRE on 1st September 1948. On that date the Central Research Establishment was placed under the local control of a Deputy Director of Research, Dr.D.C.Rhys Jones. By the end of 1949 CRE was staffed by 25 Graduates, 50 Technologists and 64 Administrative & Industrial staff, with an overall authorised annual budget of near £80,000. The land comprised 10 acres (maybe more precisely 9.913 acres) with a main building (that became known as the Hanger Building) containing offices and laboratories, plus (separately) workshops, a canteen (which continued to be used for this purpose until site closure, 50 years later), various small outbuildings and two partially completed structures (these are probably the buildings which, after completion, became the garage and PB16). By December 1949, some long serving employees were already in post, including Jack Owen (who became Deputy Director by the 1970s). CRE Stoke Orchard, apart from its proximity to the Forest of Dean coalfield which was not part of the NCB, and the South Wales No 6 (Monmouthshire) Area of the SW Division, was otherwise remote from any direct coalfield connections or allegiance. The oft recounted (unconfirmed) anecdote about the reason for the location of CRE near the spa town of Cheltenham, appears in Steve Wright's book "Fluidised-Bed Combustion, A Clean Coal Combustion Process that Nearly Was". He wrote "When, in the 1950s, much against its anti-intellectual instincts, the NCB was forced by Her Majesty's Government to indulge in some research, they needed somewhere to build their CRE. The man in charge of the project was Welsh, ... and found his ideal site at Stoke Orchard near Cheltenham. It was part of a vast World War II RAF Maintenance Base, and some of the hangers were still extant at the end of the 20th century. The NCB bought a hanger and some adjacent land and built CRE. The official excuse was that the site was sufficiently far from any coalfield so as not to be influenced by parochial interests. In fact it was closer to South Wales than any other coalfield, provided that one ignored the dying coal areas of Somerset and Forest of Dean. It was also somewhat closer to Cardiff than it was to Hobart House (NCB HQ in London). The man in charge perceived an overwhelming advantage for Stoke Orchard; he could call a meeting at CRE on a Friday afternoon and comfortably travel on to enjoy the rugby at Cardiff Arms Park the next day". |

||

|

The Central Research Establishment was set up by Dr.W.Idris Jones, formerly (from 1933) the Research Manager for Powell Duffryn Ltd. Idris Jones was appointed Director General of the Scientific Department of the newly formed National Coal Board (from 1st Jan 1947) under Sir Charles Ellis, F.R.S. (NCB Director for Research and Development). The Gloucestershire Echo, in its issue for Wednesday 15th September 1948, reported that "Research teams from South Wales and London have moved into the Stoke Orchard factory (the term 'factory' being to do with the previous Roy Fedden manufacturing activities) which has been taken over by the National Coal Board as the Central Research Establishment". Although the site was initially placed under the control of Dr.D.C.Rhys Jones, as the Deputy Director, it seems the post of Director was always intended to be held by Dr Jacob Bronowski, but he could not take up that post until spring of 1950. Another Gloucestershire Echo archive, 14th April 1950, reports him as being newly appointed. Wikipedia sums up Jacob Bronowski with the words ".......(18th January 1908 – 22nd August 1974); a Polish-Jewish British mathematician, biologist, historian of science, theatre author, poet and inventor. He is best remembered as the presenter and writer of the 1973 BBC television documentary series, The Ascent of Man, and its accompanying book". Anecdotally, he was best remembered by CRE staff for his development of Bronowski's briquettes, a form of smokeless fuel made from coal dust, but its uncertain whether they were mass produced. Anecdotally, these briquettes were also referred to as 'Bronowskis's bullets'. They may have been the forerunner of the 'Homefire' smokeless fuel briquettes which were definitely manufactured commercially, firstly at Birch Coppice pilot plant and later at Coventry, at the 'Coventry Homefire' plant. In a Financial Times article by Erica Wagner, dated 21st November 2014, I quote: "There’s a photo from Bronowski’s NCB days of him standing with Prince Philip, about to inspect some of his famous briquettes. Apparently when they actually looked at them, Prince Philip said, ‘They look just like turds!'”. The Illustrated London News archive suggests this meeting may have taken place in March 1957. |

|

|

Some of the names in the preceding paragraphs are remembered by Richard Gillings, who has written (Dec 2023) to tell me of his father's involvement at CRE. Richard writes: "My father - Dr.David

Gillings. PhD., joined the National Coal Board in 1948 He was

initially based at Hobart House, London, but transferred to Stoke

Orchard in 1951. He left the National Coal Board at the end of

1955 to take up an appointment with ICI". The earliest CRE Annual Report, covering the period from inception, 1st April 1948, until the end of 1949, was submitted to the Director General by Dr.Rhys Jones. The work of the Central Research Establishment was essentially to do with mining (especially health and safety issues), coal preparation (washery techniques), coke manufacture by carbonisation, coal combustion and refining industry byproducts, especially tar processing. The 1950 Annual Report to the Director General, from Dr.Bronowski, details the work carried out under the categories Mining, Carbonisation, Coal Preparation and Chemistry, the latter including the study of coal tars and the inorganic constituents of coal. There was even an experimental coal face being installed at CRE, presumably to further support the technology of coal mining. By 31st December 1950, staff strength totalled 239, "still 24 short of compliment". A Photographic section had been formed and also a Mathematics section, both directly responsible to the Directorate. The 1951 Annual Report showed a similar pattern of work to that of the previous year, though the number of research topics had grown significantly, as noted somewhat anxiously by Dr Bronowski in his Introduction. During 1952 an interesting change took place at CRE. The mining research topics were split away from the rest of the establishment's activities into a structure known as CRE II, which was transferred to a new mining establishment (most likely at Isleworth; 10 miles west of London). This took place during the summer months. Thence, from 1st September 1952, the remnant CRE at Stoke Orchard (CRE I) was made up of 6 sections, including two new ones, these latter dealing with: (i) the application of fluidised bed processes to coal carbonisation and (ii) briquetting. The other four were as previous, being (iii) coal preparation, (iv) carbonisation, (v) chemistry and (vi) a residual physics department not transferred into CRE II. Fluidised bed technology was being assessed for oxidising Betteshanger (Kent) coal as an aid to Phurnacite (smokeless fuel) production via the erection of a 1tph FB pilot plant, aimed to commence operation in January 1953. Dr Bronowski's introduction to the 1953 Annual Report explains the purpose of the reorganisation of CRE that took place in 1952. "...we wholly changed the accent of our work, which has since been grouped round a single problem.....to make highly efficient smokeless fuels, chiefly for the home, from the low rank, high volatile coals.....which will form an increasing proportion of the coal mined in Britain". This work was sub-divided into (i) coal cleaning (especially dust and slurries), followed by (ii) pre-treatment to make non-coking coals amenable to carbonisation, then (iii) briquetting, and finally (iv) carbonisation of the briquettes to make a smokeless fuel. Product briquettes were required "....with a high content of accessible heat....on a reasonably up-to-date open fire, on which (otherwise)..... the fraction of heat available even from good large coal is small". There are references thereafter in the 1954 Annual Report to the work of CRE I, being those involved in smokeless briquettes R&D, as distinct from the Mining R&D carried out by CRE II. A Summary Report of the work at CRE from 1952 to 1955 explains this new direction thus "The Beaver Committee Report and the Clean Air Bill (which became an Act in 1956) have increased the urgency of producing smokeless fuels and so the programme for 1956 is essentially concerned with problems with their manufacture". The research direction of CRE

had moved away from supporting the whole of the mining industry

(this had become the province of CRE II at Isleworth) and

towards 'just' supporting the utilisation aspect of coal once

it is mined Wendy Haxton, whose father, Ernest Prosser, worked at the newly formed Isleworth Mining Research Establishment (1952-1969) as head of the finance department, has told me (August 2019) that the Isleworth site was previously Isleworth film studios where a number of notable films were made, including some of the water sequences in African Queen, starring Humphrey Bogart and Katherine Hepburn. The main building on the Isleworth site is Worton Hall (see left). It has been a Grade II listed buiding (Historic England Entry Number: 1261035) since 21st May 1973 and still looks very imposing (in 2002). The author understands that the original Mining Research Establishment at Isleworth (from 1952; believed to be the 'home' of CRE II staff), and the Central Engineering Establishment at Bretby, near Burton-on-Trent, Derbyshire, merged in 1969 and formed MRDE (the Mining Research and Development Establishment). MRDE was responsible for research into, and the testing of, mining equipment and mining procedures, and was appropriately located near to the Midlands, Nottingham, Lancashire and Yorkshire coal fields. Why the original 'home' for mining research was at Isleworth, remains a mystery. |

||

|

||

|

A 1954 report on Heat Transfer in Fluidised Beds (CRE I Report No.1241, by B.A.Lilley) seems almost phrophetic in the context of the vast amount of R&D into fluidised bed application that took place from the late 1960s at CRE (from 1963 at BCURA, Leatherhead). The difference was that, in the mid-1950s the fluidised bed was being applied to the carbonisation of coals and modification of their coking properties, whereas 20 years later it was applied extensively to coal combustion. The 1954 report's summary reads: "The discrepancy between results obtained by two methods of estimating the efficiency of heat transfer from the fluidising gas to fine coal has been resolved in favour of the high efficiency result. It is concluded that heat transfer is effectively complete within a distance of less than a centimetre from the point of entry of the hot gas, and that the efficiency is therefore practically insensitive to the formation of bubbles within the bed". By the end of 1952 the staff compliment had risen to 304 (out of a required compliment of 349), leading to "serious overcrowding unless the building programme is speeded up". This concern was answered by 'new first floor laboratories and offices', believed to refer to around 20 new first floor rooms being added along (at least) the southern length of the original Hanger Building (south is towards the top in the above picture), plus a new garage building, both becoming available by January 1954 (in the mid-1953 picture above, the garage to be, centre foreground, is still under construction). A new Boiler House and Engineering Workshops were also pending (the former to be situated between the garage and the Hanger Building, the latter behind the gate house on the south side of the Hanger Building). Although ambiguous, the 1954 Annual Report suggests that construction of what became known as the 'new' office and laboratory building, located on the opposite side of the entrance roadway from the Hanger Building, commenced on 1st June 1954. By the end of that year "the roof, the greater part of the walls and many of the internal serivces were in position". In the picture above, the land where this new office building was eventually located, is still undisturbed. |

||

|

Below is another early photograph of CRE Stoke Orchard, believed to have been taken in Spring 1954, since construction of the new office building has still not commenced. This view, and several others, have been made available by an ex-CRE colleague, Dr. Nigel Paterson (who worked in Analysis and Testing Branch). Nigel says "When (the site) was closing (end of 1997), I rescued some glass plate negatives from the photographic store, which show CRE developing from the late 1940's to the mid 1960s (approx.). I put these into the Records Office in Alvin St, Gloucester. I included them in the archive of the Gloucestershire Buildings Recording Group as project number 156. I was Chair of the GBRG and wanted to make sure they were safe and remained in Gloucestershire. I did print some of them directly as the negatives are large and excellent quality". The view below looks across an open field towards the Main Hanger building. By the time of this photograph, the Hanger Building has received its new extension of a continuous row of offices at first floor level. Also, the part completed building (at the time of the site's purchase) that was to become CRE's garage building (see the extreme right hand building with the three roller shutter doors) has been completed, together with the adjoining building behind it, which was to become Process Building (PB) No.16. The site's coal fired heating boiler house, and shower block, subsequently to the left of the garage, are still absent. Comparing it to the aerial view at the top of this page, the 'gardener' in the centre foreground must be standing on what became the mown lawn at the right hand (front; southern) end of the aerial view, in front of the long office building that faced the Stoke Road. Behind the gardener is uncultivated land which has been fenced off, possibly indicating the pending start of construction of the new office building. |

||

|

||

|

|

Alongside is an August 1955 perspective view of the proposed new Engineering Workshop. The workshop is in the foreground, with the Main Hanger building behind it. The new office and laboratory building, which is believed to have commenced construction on 1st June 1954, is also shown in the right hand background as a 'L' shape (though may not have been completed at the time of this drawing). The new office building did not receive the additional 'L' shape block that completed its overall square formation (see the aerial view at the top of this page) until the mid-1970s. The small building to the right hand end of the Engineering Workshop is the canteen building, which was part of the site's building compliment when purchased in April 1948. The Engineering Workshop also incorporated the site Drawing Office, Carpentry services, Electricians and Instrumentation. The new site Boiler House, and adjacent ablutions block (including showers), were completed by January 1955. |

|

| A CRE site plan for 3rd June 1957 is shown below, and includes the Engineering Workshops and Boiler House. | ||

|

||

_cr.jpg) |

The new 'L' section offices and laboratories building, construction of which started in June 1954, is believed to have been essentially completed by the end of 1955, though it may not have been internally furnished, equipped and occupied until the end of 1956. This building is shown on the June 1957 site plan, above. Further photographs of the construction of this building can be seen here. |

|

|

During the early 1960s, the Domestic Heating 'Fuel' Laboratory was added to the far end of the 'leg' of the 'L' that is parallel to the Stoke Road. Further photographs of the construction of this building can be seen here. |

|

|

Further below is a black & white site aerial view that is believed to date to the early 1960s, probably taken not long after the Domestic Heating Appliance 'Fuel' Laboratory was completed. At this time, the northern site boundary (the right hand lower corner of the picture below) extends to the Dean Brook (see the line of trees), while the western boundary (to the right) extends to just beyond the end of the Hanger Building. The site was subsequently extended in both of these directions, as can be seen in the aerial view at the top of this page. The western extension became the site car park when the car park behind the new office building could no longer be used as such due to further offices being built on that land as related below (mid-1970s). Notice the large piece of South Wales (near anthracite; 200 Rank) coal, that became a long term feature of the entrance to CRE, on its 'roundabout' plinth in the centre of the driveway leading to the new office building foyer. That 'roundabout' is shown on the site plan drawing above, dating to June 1957, and its entirely possible the coal 'lump' was already in place by that time. Ceri Thompson (Curator at The Big Pit:National Coal Museum, Blaenafon, Torfaen, NP4 9XP) tells me (July 2017) that it originally came from 'the 9 foot seam' at Deep Navigation Colliery, near the village of Treharris in the borough of Merthyr Tydfil. A large group of visitors and staff are standing in a semi-circle behind this coal, on its 'roundabout', in the 2nd picture down from the top of this page. At the time of its acquisition, the 'Deep Navigation' coal 'lump' was believed to be the single largest piece ever mined. But in 1989 a second, even larger, coal 'lump' became available. With the approach of CRE privatisation, the mini 'roundabout' had become something of an obstruction and was removed and the first coal 'lump' (weighing about 1tonne and 2m long, 1.8m wide, 0.9m high) was stored on site in PB5 until Martyn Davis arranged for it to be sent for display at the National Museums & Galleries of Wales in July 2003. Ceri Thompson adds "this large piece of coal has been the 'star' of a film which traced the journey of coal from the valleys down to Cardiff Docks. The coal itself was on display in the National Museum Cardiff for a few months but is now resting in our Collections Centre in Nantgarw".

That later anthracite 'lump' is now stored at the Hopewell Colliery Museum in the Forest of Dean. My Thanks to 'Rich' Daniels for telling me this and confirming it with photographs. |

||

|

||

| The view below

was perhaps taken the same day as the above. By including more of the surrounding countryside, with its homes and farms, this is an interesting view for anyone researching Stoke Orchard village. |

||

.jpg) |

||

| Below is shown a view inside the Domestic Heating Laboratory, as it appeared in the visitor's guide to the June 1970 'Open Days'. | ||

The centre pages of this guide includes a site map to assist visitors to move around the site and to find specific exhibits. That site plan still labels CRE as CRE 1, referring to the 'split' that took place in 1952. |

Compared to the previous 'early 1960s' view, the northern end of the site (the right hand side) has further process buildings, but otherwise looks much the same. At that time the site Library was located in an office off the main entrance foyer of the new building, though already held "...about 8,000 books and bound periodicals, about 10,000 reports, reprints and similar....and subscribed to about 250 current periodicals". An extension building off the entrance foyer provided a much larger library in the mid-1970s. |

|

|

Perhaps the reason for CRE not expanding much during the 1960s is in part due to the 1960s being a painful decade for the British coal industry; colliery closure, a decline in overall output and employment and a depletion of known reserves were characteristic features. The great reconstruction of the mining industry during the 1950s, following coal industry nationalisation, had brought coal production back to a 1957 peak of around 228 million tonnes. But thereafter, decline set in, as imported oil, nuclear power and natural gas began to compete heavily in certain markets; further decline in coal demand was predicted by a 1967 White Paper on fuel policy and led to accelerated colliery closures. By 1974, coal annual production was down to around 110 million tonnes. Dr.D.C.Rhys Jones, who was Deputy Director under Dr.Bronowski and authored a paper in New Scientist magazine for 7th May 1959 describing new methods of producing smokeless fuels, took over the post of CRE Director in 1960. Dr.Bronowski, whose major interest by then was in the development and commercial manufacture of smokeless fuel from bituminous coal, officially known as Bronowski briquettes but also, less kindly, as Bronowski 'balls' or 'bullets' (or 'turds' - see above, visit by HRH Prince Philip, March 1957), moved to Hobart House, NCB London HQ, as ' Director General of Process Development' (until 1963) where he oversaw the construction of smokeless fuel plants at Birch Coppice and at Coventry. Dr.Rhys Jones retired in 1965 and CRE 's Director then became Dr.R.R.Gordon who was replaced in 1968 by Dr.Joseph (Joe) Gibson. Dr.Gibson stayed in post until 1977 when he became London based Board Member for Science (1977-1981). Miner's Strike and Three-Day Week The first strike occurred in 1972 over pay. It began on 9th January 1972 and ended on 28 February 1972, when the miners returned to work after accepting an improved pay offer in a ballot. During this strike, all 289 pits in England and Wales stopped work. By miners picketing power stations, the strike led to electricity cuts of up to 9hours a day around the country, on a published rota basis. Less than two years later, on 12th November 1973, the NUM began an overtime ban, which swiftly led to the Government declaring a state of emergency, as concern increased over inadequate coal reserves at power stations. The miner’s action was against the Government’s anti-inflation policies. Throughout 1973 a series of Bills had been passed that restricted income and put strict limitations on pay rises. The miner's overtime ban caused Prime Minister Edward Heath to announce, on 13th December 1973, a series of measures to conserve fuel in the United Kingdom. For a fortnight from the 17th until the 30th December, industrial and commercial energy users would be restricted to only five days of energy consumption. From the start of the new year, the restrictions would be increased to only three days of consecutive energy consumption a week – essentially enforcing a three day working week. On the 9th February 1974, a full miner’s strike commenced. The failure of Heath’s Government to effectively avert a mass strike was a key factor in its defeat in the national election of February 1974. The strike came to an end on 6th March, following an agreement between the NUM and the new Labour Government, under Harold Wilson. The Three Day Week was itself ended on the 7th March 1974. For many, the ‘Three Day Week’, and later the 'Winter of Discontent' under James Callaghan's Labour Government in 1978-79, symbolised the increasing power of trade unions to disrupt the whole country. The fear that trade unions could hold the country to ransom was a key contributor to the election of Margaret Thatcher's Conservative Government in 1979. By the time a Labour Government again took power in 1997, British Coal had been privatised, was vastly reduced in size and had lost all industrial influence. |

||

| CRE; the last 25 years | ||

|

Although the 1973 oil crisis impacted on the UK's economy, this crisis dramatically improved the fortunes of the UK's coal industry. The crisis began in October 1973 when the members of the Organization of Arab Petroleum Exporting Countries (OAPEC, consisting of the Arab members of the OPEC plus Egypt, Syria and Tunisia) proclaimed an oil embargo. The embargo was a response to American involvement in the 1973 Yom Kippur War. Six days after Egypt and Syria launched a surprise military campaign against Israel to regain territories lost in the June 1967 Six-Day War, the US had supplied Israel with arms. In response to this, OAPEC announced an oil embargo against Canada, Japan, the Netherlands, the United Kingdom and the US. By the end of the embargo, in March 1974, the price of oil had risen from $3 per barrel to nearly $12. The oil crisis had many short-term and long-term effects on global politics and the global economy. It was later called the "first oil shock", followed by the 1979 oil crisis, termed the "second oil shock." The escalation of oil prices required a UK reappraisal of the competitiveness of its neglected indigenous coal resources. Thus, the retreat from coal, that had characterised the 1960s, was halted. The National Coal Board (NCB), backed by the militant National Mine Workers' Union (NUM), exploited the sudden reversal of its fortunes to gain government acceptance of its ambitious 1974 'Plan for Coal'. This stressed the long-term importance of coal in British energy policy, arguing that investment in new capacity was vital to equip the industry to sustain and expand production to meet the day, probably in the 1990s, when an 'energy gap' might reappear when North Sea oil and gas wells began to run dry. British industry had relied heavily on coal for much of the 1950s, but had substantially moved away from coal during the 1960s when fuel oil had become relatively low priced. However, the 1974 OAPEC 4-fold oil price increase risked UK industry becoming uncompetitive in worldwide markets unless a lower cost fuel could be provided. A difficulty in coal winning back industrial users was that, during the previous 20 years, industry had become used to automatic clean operation of its combustion processes when burning fuel oil, so coal needed much development to make it acceptable again to industry. It also had to satisfy increasingly stringent stack emission legislation (1956 and 1968 Clean Air Acts) and also general public perception; they would no longer tolerate their local air quality being polluted by dust, or finding chimney smuts on their washing. The Marketing Department of the NCB (CRE's source of funding) tasked CRE with developing technologies and equipment necessary to achieve an increase in UK coal use from around 110 million tonnes per annum to (optimistically) 150 million tonnes. The electrical power generating industry (the nationalised CEGB at the time), consumed around 85 million tonnes per annum and this was unlikely to change unless by demonstration of new, environmentally clean, processes, operating at higher thermodynamic efficiency. One such demonstration process was the application of pressurised fluidised bed coal combustion (PFBC) within a combined gas and steam turbines cycle. Originally developed at the BCURA laboratories between the late 1960s and early 1970s, a large scale prototype was built at Grimethorpe colliery, in S.Yorkshire, from 1977, which was initially directed by various co-ordinating bodies and came under the day-to-day management of the British Coal Corporation's (née the NCB's) CRE by 1990. But such major R&D projects have a long lead time before they can make a material increase in coal sales. Shorter term opportunities for additional coal sales lay within the industrial, commercial and domestic heating sectors, and also in the iron and steel industry. In pursuit of these 'shorter term' opportunities to extend coal use, 'Plan For Coal' instigated an increase in the number of employees at CRE by the substantial growth of industrial combustion R&D, especially through the application of shallow fludised bed technology. Two Branches provided this effort viz; Appliance Development (AD) Branch and a newly created Branch named Industrial Development (ID). There was also additional new staff employed in similar pursuits via gasification projects, applicable to industry and (in the longer term) to power generation. These employee numbers raised the need for a further extension to the 'new' office building. |

||

|

However, an unplanned event occurred that further impacted on the need for additional office space. In late 1973, maybe early November, a serious fire occurred along the upstairs corridor of the 'new' office building (Building 37 on the site plan, below) that (in Mike Vicker's words) "gutted the ....Chemistry Department....... The front entrance to the main building was off limits during the lengthy repair/rebuild of the upstairs laboratories. .....the reception area was still being revamped after the staff had moved back into the upstairs laboratories. The staff had previously to move into the Hangar Building for about 18 months (during the repair)". Photographs of the fire damage were taken on 12th November 1973 and show that first floor rooms numbered 120 to 144, so perhaps 12 rooms on either side of the upper corridor, had suffered considerable damage. This was in the arm of the 'L' block facing east-west, maybe 1/3rd of the way along from the entrance foyer. The photograph, left, is the corridor outside room 125. Martyn Davis tells me "the man stood in the doorway is Fred Jeynes. He looked after the ground working team consisting of 'Nippy' Gilder, Derek Williams, Gerald Heath and others. He is probably there to start clearing up the mess". At this time, the Director at CRE was Dr. Joseph (Joe) Gibson, who became Director in 1968. The Directorate decided to take advantage of the need for substantial repair to what was known as the 'new' office building, to also add the additional 'L' block as shown below, making the original 'L' into a square arrangement, resulting in a surrounded central grassed area serving as a croquet lawn. This area had previously been the main site car park. Hence, as a prelude to the building of the additional office block, a new car park had to be created on land to the western end of the Hanger Building. |

|

|

The completed 'new' office building, as shown below together with its ancillary buildings, were formally opened by Dr.J.Gibson, by then Board Member for Science, on 30th November 1977. The polished metal plaque shown left was wall mounted just inside the entrance leading into the additional 'L' shaped block (opposite corner to the main entrance), to commemorate this event. With Dr.Gibson becoming NCB Board Member for Science, the role of CRE Director was taken up by Dr.David Dainton, with Jack Owen as his Deputy Director. The plaque was removed by Martyn Davis at the time of the CRE site closure and Dr.Bill Kaye passed it on to Carole Gibson, Dr Gibson's daughter. Carol Minter, who joined CRE as site librarian in (coincidentally) November 1977, arranged with Carole Gibson for this plaque photograph to be taken. The aerial view shown below dates to around 1990, by which time the Test Boiler House, with its two spiral wrapped chimneys and coal silos (left background), had been erected for novel boiler developments. An Exhibition Hall had also been erected, between the Test Boiler House and the 'new' office building, where a variety of technologies could be demonstrated to visitors. |

||

|

||

|

CRE's fluidsed bed technology was sold worldwide via a licensing organisation called Combustion Systems Limited (CSL), while making the 'know-how' freely available to UK manufacturers who applied it to the commercialisation of appliances that burned UK coal. The development of high thermal efficiency 'clean' coal power generation technologies progressed, both at Grimethorpe Colliery, with its large scale Pressurised Fluidised Bed Combustion (PFBC) test rig, and also at CRE, carrying out practical, though small scale, 'Topping Cycle' developments that subsequently became known as the Air Blown Gasification Cycle (ABGC). Directorate called upon CRE staff, as well as their own experiences, to produce frequent papers for conferences and other publications, explaining the in-depth knowledge that had been acquired on the subject of coal and all its applications, both current and potential. Click here to download a pdf of two chapters which eventually formed the basis of sections of the book "Coal Utilisation: technology, economics and policy", authored by Leslie Granger and Joseph Gibson (Graham & Trotman, 1981).

A 'paper' by Dr Gibson, with its origins in the late 1970s but formally presented at the Proceedings of the Institue of Petroleum, in 1982, entitled "Coal - The Fuel of the Future", can be downloaded as a pdf by clicking here, or on the small image alongside. |

||

|

The content is tame by modern

standards, but it was an opportunity to poke a small finger of

fun at the site's senior staff and administration. |

||

|

Some noteable success was achieved by CRE in encouraging interest in coal use by industry and commercial organisations (e.g. hotels and hospitals). Coal production steadily rose during the years to 1980, when it peaked at 130 million tonnes. However, unrest and subsequent strike action by miners belonging to the National Union of Mine Workers (NUM) began a coal sales decline that was never subsequently halted. If the decline attributable to pending strike action is ignored, then UK coal useage averaged 125 million tonnes during the 8 years following implementation of the 1974 Plan for Coal, a 15 million tonnes per annum increase.

Alongside is the cover of 16 page boklet entitled "Clean Use of Coal", giving a brief summary of all the investigative environmental work being carried out at CRE. It was published by the British Coal Corporation in 1987. To download it as a pdf, click here or on the small cover image. |

||

|

This A4 booklet on a whole range of fludised bed developments in progress at CRE and available for industrial installation by commercial organisations, was the 2nd in a series of three that were published between 1980 and 1988. it was published in 1985, when the coal industry was still run under the banner of the NCB. To download a copy as a pdf, click here, or on the small image alongside. |

||

|

The 1984 Miner's Strike During the strike certain UK industrial coal supplies were disrupted and coal imports were sanctioned by the NCB to maintain supplies. Despite the strike, work at CRE continued much as before, though it was clear that industrialists were now less keen to risk converting to coal than had been the case in 1980. The number of new industrial combustion projects dwindled and a reorganisation of CRE staff began. As the decade progressed, phrases such as 'Early Retirement' and 'Gardening Leave' became ever more commonly heard. After the 1984 strike, colliery closure accelerated as coal came under further attack as an undesirable 'dirty' fuel by the growing Climate Change lobby. More than 1,000 collieries were working in the UK during the first half of the 20th century; by 1984 only 173 were still operating. |

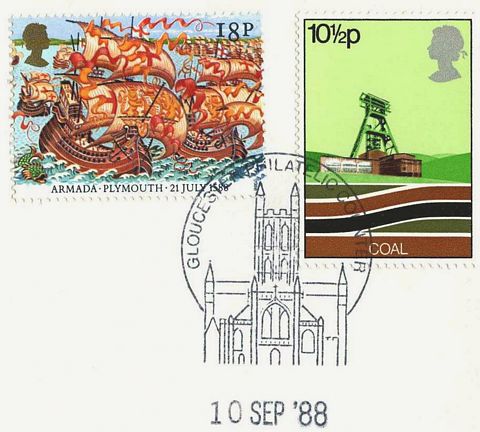

||

| Pride in the Establishment

continued despite the set-backs, as illustrated by this 1988

'Commemorative Issue' envelope, of which 300 were produced and

circulated to CRE staff members. This one has the Cover Number 140.

I believe the order in which they were issued was democratically

determined by a 'raffle ticket' draw. Each envelope contained

a card, signed by the (then) Director, Dr David Dainton,

with a brief explanation of the formation of CRE in 1948 and

the work accomplished over the intervening 40 years. The

envelopes were 'franked' by the Gloucester Philatelic Counter

on 10th September 1988. Design was by two of my ex-colleagues, Eric Smith and Tony Isles. Artwork is attributed to Frank Lappington. Printed by the Reliance Printing Works, Halesowen, West Midlands. |

||

|

The stamps are: (January 25th) 1978 Energy Commemorative (10½p 'Coal' from a set of four, incl gas, oil and electricity) (July 19th) 1988 400th Anniversary of the Spanish Armada. |

|

| Around 1989, Mr.James (Jim) Harrison became CRE Director, taking over from Dr.Dainton, with Dr.John Whitehead as his Deputy Director. Later (around 1991) John Whitehead became Director and it was he who had the unenviable task of preparing CRE for the inevitable effect resulting from privatisation of its parent nationalised coal industry, known (since 1987) as British Coal Corporation (BCC). | ||

|

CRE Organisation ~ a general overview The author of this brief historical account did not join CRE until late 1978 and so the following brief notes serve mostly to record personal memories of the organisation that he joined and the way in which this organisation changed and developed over the subsequent years up to the time that coal technology R&D came to an end in 1997. CRE was divided into various Branches, each with their separate R&D responsibilities under a Branch Head and a Deputy Branch Head. Above them came a Deputy Director (CRE sometimes had more than one Deputy Director) and finally the Director himself. Staffing levels varied but was typically 350, though I understand this figure may have peaked nearer to 500 in earlier decades. A Finance and Administration Department handled all financial transactions (though not staff wages) and included the staff Personnel Department, later to become known as Human Resources. The following description provides mere 'snap-shots' of the way CRE was organised from the 1970s through to privatisation. The structure was necessarily 'fluid' and changed significantly over time to reflect the industry's need to stay abreast of sales opportunities, arising technologies and environmental concerns. There was much emphasis on carbonisation and briquetting through until the early 1970s, followed by an emphasis on industrial combustion and gasification during the 1970s and 1980s followed by advanced 'clean coal' power-generation development taking prime position in the late 1980s and into the 1990s. This latter change was prompted by ever more vociferous concerns over Climate Change, that criticised high CO2 stack emissions from coal burned in low thermal efficiency (around 37%) pulverised coal fired power stations. This was old technology, developed in the 1920s that had become the UK's base load power production technology, consuming around 85 million tonnes of UK coal annually. From the mid-1980s, CRE began working on 'clean coal' power generation technologies with 20% higher thermal efficiency which, with the addition of carbon capture and storage (CCS) technology, would have substantially reduced atmospheric CO2 emissions. This continued until the very end of coal R&D at Stoke Orchard, in 1997. Coal liquefaction was a long term project that spanned (at least) the last two decades, awaiting the time when oil became scarce and oil prices rose sufficiently to make 'oil from coal' an economic proposition. The Scientific Branches

in the early 1980s (best I recall) were as follows: Three CRE Annual Reports from this era can be downloaded below: |

||

The 1982/83 Annual Report. Download as a PDF by clicking here or on the image alongside. |

The 1983/84 Annual Report. Download as a PDF by clicking here or on the image alongside. |

The 1984/85 Annual Report. Download as a PDF by clicking here or on the image alongside. |

|

To show the 'fluid' nature of CRE's organisation, the 1989-1990 CRE Annual Report lists the site's structure as:- Directors Branches then consisted

of: It is interesting that neither Gasification nor Coal Liquefaction featured, any longer, as standalone entities. Gasification became part of Power Generation Branch, who were studying the gasification of coal within air-blown Circulating Fluidised Bed Combustion (CFBC) as part of their Advanced Power Generation R&D. Liquefaction (essentially by then carried out at the Point of Ayr demonstration plant) is thought to have received CRE support via Science Branch's Basic Studies Group, with further support from Analysis and Testing Branch. Documents giving an in-sight into the work at CRE around this time, can be downloaded as PDFs here:

|

||

|

IEA Greenhouse Gas R&D Programme The International Energy Agency (IEA) is part of the Organisation for Economic Co-operation and Development (OECD). The aim of the IEA is to foster co-operation among the twenty-four participating countries in order to increase energy security through diversification of energy supply, cleaner and more efficient use of energy, and energy conservation. The IEA was established in 1974 following one of the so called oil price shocks instigated by middle eastern countries via OPEC (Organisation of Petroleum Exporting Countries). Amongst its first actions was to establish the IEA Clean Coal Centre (IEA CCC) with British Coal as Operating Agent. This has its H&Q in London and is a leading producer of unbiased research on the global use of coal. After the privatisation of British Coal, the operating agency function was passed to CRE Group Ltd (a privatised consultancy formed from CRE-BCC; see below). IEA CCC still operates (2017) and for the past 17 years it’s Director has been an ex-CRE senior person. Several other ex-CRE staff have worked for it and some continue to do so. Another IEA operation is the IEA Greenhouse Gas R&D programme which began as an exercise pertinent to British Coal’s strategy to defend the importance of coal in the global economy. It formally came into existence in 1991 and operated from CRE Stoke Orchard using (originally) several CRE-BCC staff and later a number of employees of CRE Group Ltd. It was the late 1980s when wide concerns started to emerge about global warming without too much supporting evidence at that time. But it was becoming a concern to British Coal’s main Board. So, CRE was asked by Malcolm Edwards, then BCC Commercial Director, if there iwas anything that could be done technically to alleviate CO2 emissions, particularly from power plant. It was well known that amines could extract CO2 from flue gases, but that it would add as much complexity as Flue Gas Desulphurisation (FGD), and with all the commensurate costs to power production. CRE's Process Assessment and Development Branch (PADB - see above) used their mathematical process models to investigate and its first Branch Report on the topic was published around 1989. CRE Management spent a lot of time travelling, presenting and generally getting governments and power industries to take an interest in establishing the IEA Greenhouse Gas R&D Programme. A dozen countries signed up and it came into force in November 1991 with British Coal - CRE as the Operating Agent. Despite the closure of British Coal and CRE, this work is still on-going 26 years later (in 2017). Its Director for the past ten years has been an ex-CRE and ex-CRE Group employee. |

||

| The plan below shows the overall CRE site layout, essentially as it looked from 1985 to privatisation in September 1994, through combining information from November 1989 and August 1994 drawings. The 'key' beneath indicates building designations and uses. Note that it includes a pre-fabricated building No.84, that housed the fledgling IEA Greenhouse Gas R&D Programme staff. | ||

|

||

| Site 'Key' | ||

| 1

Process building No.1 2 Process Building No.2 3 Ash Collection 4 Process Building No.4 5 Process Building No.5 6 Process Building No.6 7 Process Building No.7 8 PB8 - Power Generation Test Facility 9 Process Building No.9 / ISEP 10 PB10 - Chemical Studies & Gasification 11 Process Building No.11 12 Boiler House Annex 13 Compressor House 14 Canteen 15 Process Building No.15 / Fire Station 16 Process Building No.16 17 Coke Oven Building 18 Simon Carves Oven 19 Gas Meter House 20 Gas Meter House & Compressor House 21 Gas Analysis Laboratory 22 Coal Store 23 Pumping Station (Lagoon) 24 Coal Store 25 Sample House 26 Store (Nisson) 27 Electrical Sub-Station No.2 (Intake) 28 Electrical Sub-Station No.1 29 Process Building No.29 30 Domestic Fuel Laboratory |

31

Process Building No.31 32 Gate House 33 Chemical Stores 34 Radioactive Material Store 35 Site Cooling Water 36 Engineering Workshops 37 'New' Offices and Laboratories 38 Main Research & Administration 'Hanger' Building 39 Boiler House 40 Design Office 41 Planning Office (nee Carpenters Workshop) 42 PB7 - Storage Area 43 Electrical Workshop 44 Precision Engineering Workshop 45 Ablutions 46 Process Building No.46 47 Pneumatic Conveying Test Rig (nee FBC test facility) 48 Process Building No.48 49 50 Coke Testing Building 51 Store (Nisson Building) 52 Store (Nisson Building) 53 Redundant Equipment Store 54 Liquid Nitrogen Storage 55 Process Building No.55 56 PB56 - 350kW Fluidised Bed Test Facility 57 Car Park 58 1MW Boiler House 59 Drum Storage (Solvents) 60 Laboratory Gas Supplies |

61

New Office Block 62 Process Building No.62 63 Building Stores 64 Ash Storage 65 Coal Storage Bays 66 Process Building No.66 67 Test Boiler House 68 Exhibition Centre 69 Coal Store Building 70 Process Building No.70 71 Gasification Plant 72 Site Steam Boiler Capsule 73 Coal Storage & Handling Facility 74 Process Water Supply 75 Coal Crushing & Drying Plant 76 Timber Framed Houses 77 Process Building No.77 ( 20bar PFBC) 78 7 kg Coke Ovens 79 7 kg Coke Testing 80 Propane Gas Compound 81 82 Gardener's Compound 83 CDR 84 IEA Greenhouse Gas R&D Programme 85 86 Raw Material Store 87 Lysimeter Compound |

|

Privatisation and Closure The story now moves on to 1993, by which time, to quote Steve Wright, "It was clear to all that with the sale of the rump of the coal mining industry to the 'Private Sector', CRE could not continue in anything like its existing form. If there was no UK coal industry to speak of, an establishment the size of CRE Stoke Orchard, with 300 to 400 [300 by then] employed, would be difficult to sustain or justify". The UK coal industry, and CRE along with it, was inevitably going to be impacted by an exciting new world of privatisation.

The A4 booklet alongside, entitled "CRE Review" was produced to act as a marketing tool for the skill set available within the CRE work force. To download a copy as a pdf file, click here or on the small image alongside. The opening paragraph reads "During 1991 we undertook a fundamental review of our business, which resulted in the formulation of a new strategy, based on our existing range of activities, but with a substantially enhanced customer base. At the same time, we restructured our organisation and programme, with effect from March 1992". A newsletter appeared around this time, called "CRE News", probably intended to prepare the CRE work force for the new circumstances and pressures they were to find themselves working under. It was 'upbeat' in its approach, reassuring everyone that plans were in place to meet any new challenges. The May 1992 issue can be downloaded as a pdf by clicking here. Two years later, the reality of privatisation proved less assured than the optimistic impression to be gained from these documents. |

||

|

In mid-June 1994, John Whitehead made an announcement about CRE's future. It was proving impossible to reconcile the various functions of CRE and therefore it would have to be split. Those areas of business which were thought to have a long-term future (five years or more?) would be bundled into a new company called 'CRE Group Ltd', a subsidiary company of British Coal, for which bids would be invited from the Private Sector. The new company would have a portfolio of activities including consultancy, technical support services and small-scale research. Thence, the Stoke Orchard workforce was divided into three parts. An 'A team' of employees was allocated to CRE Group, a 'B team' was allocated to a new Coal Technology Development Division (CTDD) and a 'C Team' were offered more or less immediate redundancy. Very roughly, the approximate remaining 300 workforce (some had taken voluntary redundancy in the preceding years) were apportioned near equally between these three Groups. The advanced power generation (APG) R&D programme was to be completed by British Coal before its final demise within the new ‘Coal Technology Development Division (CTDD)’, which encompassed the previous CRE APG Branch together with supporting services, principally Engineering and elements of Materials and Physics branches. The split into CRE Group and CTDD was timed to occur on 1st September 1994. The Liquefaction demonstration plant at Point of Ayr, North Wales, came into CTDD, with a similar short-term future. The total CRE site was sold to IMC Group Ltd when they won the bid to purchase CRE Group Ltd in October 1994. The industry-wide administrative functions of British Coal were transferred to a new authority, the Coal Authority, and all economic assets were privatised. The English mining operations were merged with RJB Mining to form UK Coal plc. British Coal was wound up on 26th January 1997. This Wiki reference is credited to Companies House, but the final, final, date seems obscure. The 31st December 1997 seems a better 'fit' with the ending of CTDD activities and the closure of Eastwood Hall, in Nottinghamshire (National Area Office for the NCB from nationaliation but now, November 2020, a luxury hotel). Then further, a Department for Enery and Climate change (DECC) document states that "British Coal ceased trading in December 1994 (perhaps referring to when the collieries were sold), but was not finally wound up till 2004". In 1997 the IP (Intellectual Property) of BCC/CTDD was split and sold: put very simply, PFBC (Pressurised Fludised Bed Combustion) IP went to ABBCarbon; GT (Gas Turbine application to coal derived fuel gas) IP went to EGT (European Gas Turbines; later GEC Alstom); HGCU (Hot Gas Clean Up technology) and materials to Cranfield, pressurised gasification and early FBC IP went to Babcock Power. Liquefaction IP stayed with DTI as having possible future 'strategic' value. |

||

|

A CRE Group Ltd corporate gift - a Parker pen in a plastic case |

||

|

CRE were not involved in any full-scale ABGC power plant demonstration. For several years prior to the creation of CTDD, CRE had been operating various pilot-scale research rigs, primarily to demonstrate their novel gasification process (two-stages; a fluidised bed gasifier and a circulating fluidised bed for residual high carbon char combustion) and a test rig for developing what became known as the 'Hot Gas Clean-up' process (invloving chemical sorbents and ceramic element filtration). The work on these test rigs needed to be completed, and it was to this end that the new 'Coal Technology Development Division (CTDD)' was created. No long-term future was seen for CTDD; any further large-scale research for ABGC would have to be carried out by interested industrial partners. A CTDD report commissioned by the UK's Department for Trade and Industry (Dti), managed by the Energy Technology Support Unit (ETSU) at Harwell, was published in 1996. Although having the primary intention to assess the relative power generating efficiency and capital cost of the UK's ABGC versus competing GCC concepts elsewhere, and especially the merits of using air or oxygen in the coal gasification process, much general background history and technology are contained within it. Thus, it provides valuable insight into the status of GCC technology at that time. See:

CTDD occupied the original 'Hanger Building', as acquired by the NCB from Roy Fedden in 1948, and continued to access this and other process buildings on the west side of the site until CTDD's work came to an end in December 1997. Thereafter, all the site buildings, apart from the 'New' laboratory & office building occupied by CRE Group Ltd, started to fall into disrepair. Photographs of this area of the site after 10-13 years of decay, can be seen here (November 2007), here (26th March 2008), here (25th January 2009), here (February 2009), here (26th June 2010), here (June 2010), and here (believed also to be June 2010). Steve Wright wrote that Alan Laughlin (Personnel Dept) was the last British Coal employee to leave CRE when he took a final load of waste paper to the site skip around 15:00hrs on 31st December 1997. |

||

|

Dr John Topper joined CRE in 1975, becoming Deputy Head of Industrial Development Branch (ID; under the excellent Doug Willis who sadly died in Spring 2019) and subsequently ID Branch Head (within 1981-88). He then became Head of Project Assessment and Development Branch (PADB) from 1988 and was also Secretary to the Director's meetings. It was John Whitehead (CRE Director) and John Topper who together envisioned an employment future for a select team of CRE employeees, to carry out overseas consultancy work at 'margins' that would secure not only the salaries of Group's more expensive staff, but also help to support 'low margin' work for other staff working in the UK e.g. domestic and industrial combustion and environmental stack monitoring. It was on that basis that British Coal was persuaded to set up CRE Group Ltd. John Whitehead became Managing Director of the new CRE Group and John Topper became Commercial Director. 95 staff initially joined CRE Group. Ownership of CRE Group Ltd went to tender in 1995 and the front-runners were a Management Buy-Out (MBO) and International Mining Consultants (IMC) Group Ltd (which had grown out of a British Coal subsidiary, 'International Mining Consultants', set up in the 1980's to sell UK coal mining expertise worlwide). The IMC bid was successful and included purchase of the whole CRE site. IMC subsequently sold the site for housing though with CRE Group (and its successors) retaining a long lease (20 years ?) for its part of the site, being within the 'new' office block to the right of the site entrance. CTDD occupied the main hanger building, though CTDD was already (or near to) being closed by the time of the site's sale. Group management knew that, without an expectation of winning high margin overseas consultancy projects, CRE Group would not have gotten 'off the ground' and 95 people would not have benefited from a further 6+ years employment. Taking part in such projects was not new to certain CRE staff, as the future commercial value of developing an overseas consultancy capability had been recognised by 1990. Early projects were carried out in the People's Republic of China and in the former Soviet Union. The list below is likely incomplete, but shows the overseas consultancy work undertaken in the early 1990s (while staff were still employed by CRE-BCC) and follows through into an extensive period of 6 years for CRE Group. Some CRE-BCC and CRE Group Ltd International Projects (1990-2000)

The first several years of CRE Group were successful, as Group was able to follow its original plan. Income was supported by funds arising through projects carried out for the Agencies, viz: UK Overseas Development Agency (ODA), 'UK Know-how Fund', the EC Tacis and Phare programmes, the European Bank (EBRD), the World Bank Global Environment Facility (GEF), the Asian Development Bank, (ADB) and the UK DTI. But the tide started to turn when all these revised their policies in a way not favourable to coal. Thereafter, the international coal-based consulting business went into decline. (The author of these notes,

having left CTDD employment in Spring 1997, is not certain of

the company name changes and dates in the following paragraph

and would welcome more authoritative information). |

||

|

|

For several years the environmental emissions monitoring team was a very successful part of CRE Group Ltd activities, and had been for over a decade before BCC privatisation and the formation of CRE Group Ltd. They obtained their UKAS (United Kingdom Accreditation Service; formerly NAMAS, National Measurement Accreditation Service) accreditation and used two mobile laboratories (6.5tonne converted Mercedes-Benz 608D integral vans) to house an impressive array of continuous stack gas analysers. They had formed out of CRE's EC (Envionmental Control) Branch and were used in BCC's marketing efforts to support UK coal burning customers when they had need of quantified emissions monitoring to supply to a local authority or to the Environment Agency. They also did more fundamental research as part of EU sponsored environmental projects. While this service to industrial coal customers was originally paid for by BCC Marketing, the privatised CRE Group Ltd subsequently sold these services nationwide, to anyone requriring them. Particulate monitoring was carried out manually by means of in-duct iso-kinetic sampling probes, gas analysis was done used heated sampling lines feeding gases through commercially available continuous analysers, while specialised measuring of emissions such as dioxins and heavy metals was carried out using equipment partly developed by the monitoring team. |

|

Gastec at CRE One small contingent of ex-CRE employees continued to work from the Stoke Orchard site until the end of May 2015. Gastec at CRE Ltd took over the previous domestic-heating laboratory and converted it to testing gas appliances. The Gastec group of companies provides bespoke services to clients from the gas landing point through to the burner tip and beyond, from centres in the UK, Netherlands, Bulgaria, Italy, China and Turkey. UK clients access these services from GASTEC at CRE Ltd (GaC). In addition to energy consultancy, GaC provides training and ACS (Accredited Certification Scheme) assessment for gas operatives and certification of a range of gas-fired appliances to European and other standards. From 1st June 2015, this small organisation, now named Kiwa Gastec, opened a new Training Centre, installed with a wide range of appliances, and offer Industrial Boiler Assessment (IGAS) as well as their previous domestic appliance assessment. They are still located on the Stoke Road, but a short distance closer to Bishops Cleeve (almost opposite Cheltenham North Rugby Club). Kiwa Gastec, née Gastec at CRE Ltd, is run by Mark Crowther, who was previously Head of CRE's Domestic and Commercial Development Branch (from 1989). Mark finally said goodbye to the ex-CRE site on Friday 29th May 2015, see pictures below. Martyn Davis subsequently organised some final equipment and materials clearance prior to turning out the lights and locking the doors for the last time, and handing over the keys to the demolition contractors, Conlon Ltd. This was maybe a week later, in early June 2015. |

||

|

.jpg) |

|

Site Clearance All of the site and its buildings, apart from the 'New' office & laboratory building which was still occupied by CRE Group Ltd and Kiwa-Gastec (nee Gastec at CRE), fell into disrepair and decay after it was abandoned following CTDD closure at the end of 1997. The abandoned part of CRE site (maybe 3/4 of the total area) was demolished, cleared and re-developed for housing, starting from around mid-2011 (?). The following photographs deal only with the subsequent demolition and clearance of the relatively small area including the 'New' building, after its final tenants, Kiwa-Gastec, left at the end of May 2015 (see the Mark Crowther photographs, above). By this time, the rest of CRE site had already become a housing estate, though with some building work still in progress at the far (northern) end. From June 2015, Conlon Ltd lost no time in clearing the remaining site for re-development by Bloor Homes into 'The Orchard', a modern, high density, housing estate (see lower down this web page). By the end of 2015, little remained apart from piles of rubble, as the following photographs show. My thanks go to John Eckersley, who has been in touch (September 2017) following Nigel Paterson letting John know about this history web page (see the early site construction photographs Nigel rescued before demolition). The views (including two short videos) show the final demolition of what was the earliest constructed part of the 'New' office & laboratory building, from a location along the roadway from the site entrance gates and near to where the double doors into the original 'Hanger' building would have been. Coincidentally, some of Nigel's rescued photographs show the same building being constructed, about 60 years previously, see here and here. John believes he was the last ex-CRE person (even after Martyn Davis) to enter the 'New' office & laboratory building. He gained access with one of the Conlon demolition engineers, as he wanted to acquire mementos from his old chemistry lab. |

|

|

The upstairs Chemistry Laboratory corridor, a similar view to the 1973 fire damaged corridor, see above. |

View looking North from the opening shown right. Notice that building of new houses is in progress even as the old building is being demolished. |

View through to the connection made between the original mid-1950s 'New' building and the Eastern side building erected in the mid-1970s. The opening looks North. Notice the new houses in the distance. |

|

Looking to the main Reception entrance of the 'New' Office and Laboratory Building. The foreground is the boundary with the western part of the site, which had been occupied by CTDD until December 1997. Buildings in the western and northern parts of the site had been demolished, starting around mid-2011. Those areas of the site were already housing at the time this Dec. 2015 photograph was taken. |

To the extreme RHS are the original Reception entrance doors. |

The upper floor, showing the Main Conference Room |

|

As above and left, but with the Main Conference Room almost entirely gone. |

|

Click the image to download a MP4 movie file |

Click the image to download a MP4 movie file |

|

Little remains, except debris. |

|

CRE's Legacy ~ A Personal Statement Quoting Francis H. Wilson, M.I.Min.E, from his 1913 book entitled 'Coal'; "Great Britain undoubtably owes her wonderful position among the great nations of the world to her vast store of that natural source of energy - Coal. Without a cheap and plentiful supply of this natural mineral, the industries of the country could never have attained their present prosperous condition and importance..." For almost 300 years, coal from UK mines fuelled its industrial revolution. Coal was used to power steam driven ships and railway trains, provide steam power to industry, fuel gas for lighting & heating homes and factories, provide metallurgical coke to a once vast iron & steel industry and, by the 20th century, provide electrical power to (eventually) all the population. These markets dwindled with time until, by the 1970s, electricity generation was by far the remaining largest consumer, though with a respectable tonnage still being sold into industrial, commercial and domestic markets. However, privatisation of the UK power generating industry in 1990 (née the Central Electricity Generating Board, CEGB) put in jeopardy the last major coal market and, in consequence, the entire coal industry. From 130 million tonnes of coal being mined per annum in 1980, by the end of 1994 when the British Coal Corporation was re-privatised, UK coal production had fallen to 50 million tonnes. For further comparison, consider that the UK mined 290 million tonnes per annum in 1913 and had a workforce of 1.05 million, but by 2013 UK coal production was down to a mere 13 million tonnes. In 2015 the last three large UK deep mines closed (Hatfield Colliery, Thoresby Colliery and Kellingley Colliery) and four surface mines closed (Earlseat, Laigh Glenmuir Site, Butterwell Disposal and Lodge House), such that UK production fell below 10million tonnes (Ref: Coal in 2015: a UK Gov't Special Feature article by Chris Michaels, Coal Statistics). The Institution of Chemical Engineers magazine for October 2017 contained a brief note entitled "Coal slump continues" with the news that, in July 2017, just 2% of the UK's electrical power came from coal, the lowest level in the 135 years since the UK's first coal fired power plant started up in 1882. That was a fall from 4% in July 2016 and 22% in July 2015. The National Grid reported that the 21st April 2017 was the first day that the UK had produced no electricity at all from coal. So the end of the 20th century quickly became the end of the age of coal, at least in the UK. Whether this was for political, economic or environmental reasons, is open to debate - no doubt a combination of all three. Coal is certainly the highest CO2 emitter of the fossil fuels, per unit of useful energy, but environmentalists sometimes give the impression that only coal is responsible for global warming, while no fossil fuel is exempt. And transporting supposedly CO2 neutral biomass fuels long distances, but using fossil fuel as the motive energy, seems an odd alternative. When I joined the coal industry, in 1978, one of the earliest statistics I learned was that, at the (then) current rate of usage (let's say 120 million tonnes per annum), the UK still had 300 years of this indigenous fuel reserve. But once a mine is closed, it cannot simply be re-opened, as the maintenance needed in order to keep a mine safe must be carried out as an ongoing activity. The coal is still there, but accessing it again would require substantial investment. That the UK's coal was mostly accessible only by costly deep-mining technology, was the Achilles' Heel of the industry. Several countries, with large areas of unpopulated land, operate huge open-cast coal mines, where coal can be extracted at significantly lower cost than from UK deep mines. Even with long haul transportation, imported open-cast coal is often the cheaper option. There are also factors such as low sulphur content (avoiding costly emissions abatement equipment) and low chlorine content (an indicator of a coal's tendency to foul heat transfer surfaces) which can favour imported coals. While it is comforting to know that one's country has 300 years of indigenous coal reserve, we live and work within an ever more competitive global economy. Speculating about long term problems that may emerge from relying upon imported fuels, while ignoring its immediate economic advantages, leaves one's manufacturing base vulnerable to overseas competition. This is especially true in a developed country where labour costs are high, since labour is a greater component when burning coal than with other fossil fuels. And the environmental argument against coal, while perhaps over-stated, needs to be addressed, especially in the context of meeting EU, International and moral obligations. The preceeding paragraph was written about 6 years ago (2016). Whether the UK Government still believes it sensible to rely upon imported energy from unfriendly countries must be under renewed consideration after Russia's invasion of Ukraine on 24th February 2022. The World Order has been turned upside down by this act and no one yet knows where it might lead. If WW3 can be avoided, it must serve as a wake-up call requiring wider factors to be considered than simple economic drivers. The scientists and engineers who worked at CRE have left a legacy of well researched information that may find application in the future; if not directly to coal, it may have a relevance to other technologies yet to emerge. Whatever its future usefulness, the information from CRE, and also from BCURA, Grimethorpe and Point of Ayr, has been preserved and is stored in the library of North of England Institute of Mining and Mechanical Engineers (NEIMME), Neville Hall, Westgate Road, Newcastle upon Tyne, Tyne and Wear, NE1 1SE (in May 2006 contact details were: tel. 0191 2332459; e-mail: librarian@mininginstitute.org.uk). As it says on its Home web page (http://www.mininginstitute.org.uk) "We don't deep mine for coal anymore but the NE still leads the world in keeping the industry safe". Steve Wright, in his polemical book on the Grimethorpe PFBC development, says that "Apparently, the NCB (as it was at nationalisation) was the only nationalised industry named in the Public Records Act. Every scrap of paper had theoretically to be offered to the National Archives of the Public Records Office (PRO) based in Kew, before further disposal. Once CRE Group became a wholly owned subsidiary it was no longer covered by the Public Records Act. However, all its reports and files prior to CRE's privatisation were required. It was finally established that the PRO only really wanted copies of reports and some 'important' files". These latter were provided to Kew and copies made so that "In fact all the files went into the British Coal archive (NEIMME) for storage on behalf of the PRO". One important (to this author) set of documents that, to the best of his knowledge, were destined not to end up at the NEIMME, was the Combustion Systems Ltd (CSL) Fluidised Bed Combustion (FBC) Design Manual. This multi-component, loose leaf (for amendment purposes) Design Manual became part of the Intellectual Property contained within the sale of CRE Group Ltd to IMC Group Holdings Ltd; presumably because it was seen to be of commercial value, since its contents had been licensed (for a fee) to a number of organisations worldwide, especially throughout the 1980s. In 2005, the author approached the small remnant BCURA coal research funding organisation based in Cheltenham, for their advice on whether this Manual might be rescued and put into the public domain. It encompassed most of the information on shallow bed FBC from the work of CRE's ID & AD Branches between 1974 and 1994, plus earlier deep bed FBC, including oil burning, carried out at the Leatherhead Laboratories of BCURA from the autumn of 1963. Steve Wright, who was 'in' on the very beginnings of UK FBC R&D, recollects this clearly in the opening chapter of his book. Casella CRE Energy (who owned CRE Group by 2005) were approached on whether they had any objections to the CSL Manual being retrieved back into public ownership and they kindly agreed, since they had no foreseeable use for its technology. Thence, by private funding made available by Dr William (Bill) Kaye, previously a Deputy Director of CRE in charge of AD & ID Branches (plus the Domestic Heating Laboratory), scattered remains of the Manual were pieced together and, by 2008, made available as a searchable CD containing a series of PDF files.

The CSL Manual is publically available on-line at the University of Bradford library and also here. |

|

|

CRE Stoke Orchard site in June 2017

Lyn Stephens had an impressively varied working and social life. The author spent time working with Lyn at a 10MW (thermal) demonstration fluidised bed boiler located at Rists Wires and Cables, Newcastle-under-Lyme. Nothing was ever too much trouble for Lyn. He was always in good humour, which made working with him a pleasure, a sentiment I know will be echoed by all my colleaguies who came into contact with him. The photograph alongside was taken on 20th November 1985, when Lyn was aged 58. I had to drive past the old CRE site on my way to Bishops Cleeve, so I stopped for a short time and took a few photographs to record what had happened to the site since Martyn Davis turned out the lights and locked the main entrance foyer doors in early June 2015. It had been totally re-developed by Bloor Homes into a large housing estate, such that, even for someone who worked at CRE for near 20 years, I found it difficult to imagine it was the same plot of land. |

|

|

|

|

|

|

|

The 'new' office and laboratories building was located in the general direction of this view |

The Main Hanger building would have previously been on the right hand side of this picture. |

|

|

|

|

|

|

Introduction

Introduction I

had much respect for many of the colleagues who I worked with

during my time at CRE (September 1978 to April 1997) and endorse

a belief that CRE representated a globally recognised source

of high-quality coal science. Visitors regularly came to CRE

from all around the world to witness and discuss our work (as

can be seen in photographs below), while CRE representatives

made similar overseas visits to mutual benefit.

I

had much respect for many of the colleagues who I worked with

during my time at CRE (September 1978 to April 1997) and endorse

a belief that CRE representated a globally recognised source

of high-quality coal science. Visitors regularly came to CRE

from all around the world to witness and discuss our work (as

can be seen in photographs below), while CRE representatives

made similar overseas visits to mutual benefit.

.jpg)

Other

buildings were added to the 'new' office block.

Other

buildings were added to the 'new' office block. The

domestic heating laboratory staff had two full scale domestic

semi-detached houses erected at CRE site as 'Heating Equipment

Test Houses' (see picture, left) and also attended and monitored

household customer trial sites in 'the real world'. The picture

alongside shows the two test 'houses' as they looked some 12

years after their use was abandoned, maybe November 2008.

The houses, and the area surrounding them, had fallen into disrepair.

Picture taken from the website

The

domestic heating laboratory staff had two full scale domestic

semi-detached houses erected at CRE site as 'Heating Equipment

Test Houses' (see picture, left) and also attended and monitored

household customer trial sites in 'the real world'. The picture

alongside shows the two test 'houses' as they looked some 12

years after their use was abandoned, maybe November 2008.

The houses, and the area surrounding them, had fallen into disrepair.

Picture taken from the website

Its

'Foreword' file announces:

Its

'Foreword' file announces: On