| Early Gevaert colour materials - researched by Michael Talbert |

|

Gevacolor

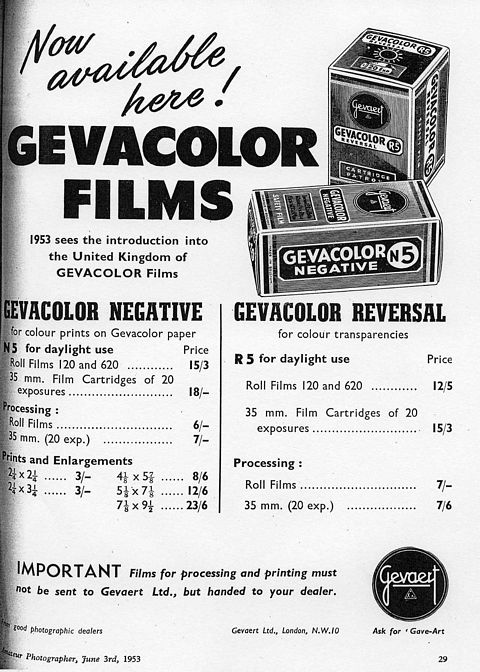

N5 colour negative film for daylight By 1955, Gevaert had introduced new colour negative films of increased speed. The daylight film speed was increased to 25ASA (ISO), and the new film was known as “Gevacolor N5–26” for a time. The “26” was the speed measured in “Scheiner”. The Scheiner speed system was used mainly on the continent at that time, but by the early 1960s the Scheiner speed system was obsolete, as photographers were using the American ASA system, and the film lost it’s “-26” suffix. The speed was increased again to 40ASA (ISO) in 1962, possibly to keep pace with other colour negative films such as Kodacolor, 32ASA (ISO), Agfacolor CN 17, 40ASA (ISO) and Pakolor Super 40, 40ASA (ISO). The last Gevacolor negative film for daylight was “Gevacolor N5 Mask”, introduced in March 1963 as a sheet film of 40ASA (ISO). It was similar to Agfacolor CN 17M, introduced at about the same time. By 1964 Gevacolor N5 Mask was obtainable in the usual roll film formats and 35mm. As it’s name suggests, the processed negatives exhibited an orange colour “mask”, much like a Kodacolor negative. In July 1964, the two companies Agfa and Gevaert joined forces and became “Agfa-Gevaert”. Gevaert continued to manufacture their photographic products in their familiar red packets and boxes labeled “Gevaert” for a time after July 1964, but by 1966 Gevacolor N5 Mask film had been replaced by Agfacolor CN 17S colour negative film, later to become Agfacolor CNS film and products were labeled “Agfa Gevaert”. |

||||||||||||||||||||||||||||||||||||||

|

Gevacolor

N3 colour negative film for artificial light The Focal Press Photo Guide, No.78, “All about colour with Gevacolor”, published in 1960, confirms that Gevacolor N3 was only available in sheet film format at the beginning of the 1960s, and the film by then had lost it’s pointless “-24” label. The speed of Gevacolor N3 film was increased to 20ASA (ISO) in 1962, but unlike the N5 film a masked version was never made. It is likely that manufacture of the film ceased in 1965 and the nearest equivalent replacement film was Agfacolor CN 17 sheet film. The two films were not identical. |

||||||||||||||||||||||||||||||||||||||

|

Processing

Gevacolor Negative films, N5 and N3

Notes:

|

||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||

|

The structure of the early Gevacolor unmasked negative films were very similar to the two Agfacolor negative films (CNT and CNK) of that time. A black anti-halation layer was applied to the base of the film and on top of this was coated an emulsion which was sensitive to blue and red light. The emulsion incorporated a colour coupler which reacted with the colour developer to produce a cyan dye in the exposed areas of the layer. Following on top of the cyan dye layer was an emulsion which was sensitive to blue and green light, also containing a colour coupler producing a magenta dye in the exposed areas. Because both layers were sensitive to unwanted blue light, a yellow filter was coated on top of the blue and green sensitive emulsion, preventing blue light from penetrating and so preventing it from affecting the two emulsion layers below. Thus, the two lower layers were affected only by red and green light, rerspectively. The upper layer, coated on top of the yellow filter, was sensitive to blue light only and contained a colour coupler which produced a yellow dye. Colour development produced three dyes plus a silver image. The unwanted silver image was removed in the following Bleach and Fix stages, leaving a pure dye image. Information on much of the

technology for the manufacture of a three colour negative film

and a corresponding three colour printing paper was published

in the FIAT reports at the end of World War II. FIAT stands for

Field Information Agency, Technical. By 1947, this information became freely available to companies outside Germany, such as Gevaert (in Belgium), Ferrania (in Italy), and Telko (in Switzerland). |

||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||

|

The last colour negative film manufactured by Gevaert was "Gevacolor N5 Mask". In addition to the reversed colour dyes generated during colour development, an orange / red mask was formed in the cyan dye layer and the magenta dye layer. The orange / red mask improved the colour rendering in the print, yellows appeared brighter and more saturated, magentas were less yellow, and greens, always a difficult colour to reproduce well, became brighter and less blue. Mask

Formation in the Cyan Layer Mask

Formation in the Magenta Layer |

||||||||||||||||||||||||||||||||||||||

|

Processing Gevacolor N5 Mask Negative Film As with the previous unmasked

films, N5 Mask was processed at a temperature of 68 +/– ½°F

in the colour developer, and a temperature range of 63°F

to 72°F for the remainder of the processing solutions and

washes.

Total process time, not including drying, was 64½ minutes. This produced a colour negative suitable for printing onto Gevacolor M8 paper. |

||||||||||||||||||||||||||||||||||||||

|

|

|

|

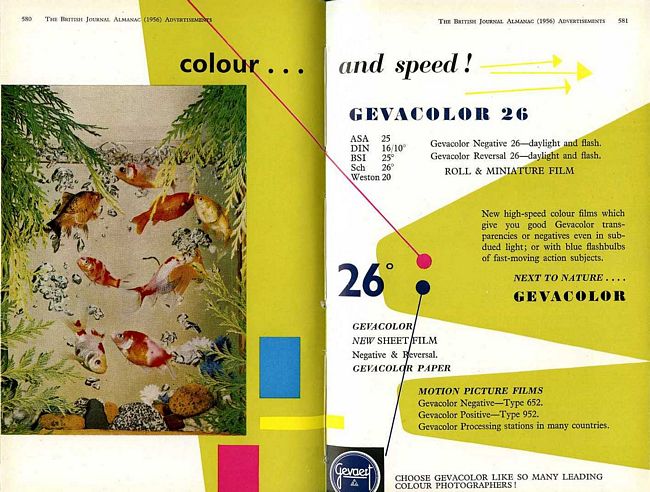

This Gevacolor booklet consists of 20 pages, with advice on “Negative or Reversal Film”, “What to take”, “Exposure”, and “Flash Photography”. Aimed mainly at the amateur photographer, it is illustrated with many colour pictures and coloured diagrams. Some of the colour photographs printed inside have been reproduced with too much contrast but on the whole the book contains a lot of useful information, plus a very good exposure table for both negative (N5) and reversal (R5) films. Inside are two price lists dated April 1958, so the booklet is likely to date to a similar time. Gevacolor R5 120 film cost 18 shillings and 2d, including processing (92p). Gevacolor N5 120 film cost 10 shillings and 10d not including processing (54p). The processing charge for a 120 film was 6 shillings and 6d (32p). An “en print” was

2 shillings and 9d (14p) for a print about 4 inches square from

a square 120 negative. The booklet price of 2s.6d (half a crown) was the equivalent of the modern day 12.5pence. |

|

|

Below is a simple exposure guide for daylight, artificial light and flash bulb photography using Gevacolor N5 colour negative film (as above) plus Gevacolor R5 reversal film, and black & white Gevapan negative and reversal films. It is believed to date to April 1961. |

|

.jpg) |

|

.jpg) |

|

|

|

|

Gevacolor paper was coated with three light sensitive emulsions onto a paper base support. The emulsion layers were coated onto the paper support in the same order as used with the negative films, i.e. starting with the red sensitive layer on the base, followed by the green sensitive layer in the middle and lastly the (upper most) blue sensitive layer. Notice that this blue sensitive layer was coated directly onto the green sensitive layer; there was no yellow filter layer. This was possible by using silver chloride based emulsions for the green and red sensitive layers, thus rendering them practically insensitive to blue light. Omitting the yellow filter layer improved the definition of the print image. At one time during the 1950s the layer order may have been changed. Some literature suggests that the green sensitive emulsion may have been coated onto the paper base with the red sensitive emulsion in the middle of the pack. This is from one source, dating from 1958, but Michael has insufficient Gevacolor technical literature available to confirm this. When it was first produced, Gevacolor paper was only used by Gevaert Ltd. and was not available for sale to amateur or even professional photographers. The emulsions were coated onto a byrata covered paper base, possibly of double weight thickness, with a glossy surface. The paper was of "normal" contrast, but by the mid 1950s the paper was supplied in three contrast grades, "Soft", coded "Z", "Normal" coded "N", and "Vigorous", coded "V". The "Vigorous" grade was equivalent to a "Hard" contrast, suitable for soft or underexposed colour negatives. This paper would have been similar to the Agfacolor paper coded CH III. |

|

Printing on Gevacolor Paper or Gevacolor Positive

Film Gevacolor prints could be made by “white light” (subtractive) , or “Tri Colour” (additive) printing methods. Subtractive (White Light) Printing Making prints on Gevacolor paper by “White Light” techniques followed the same procedures as if printing on any other type of colour printing paper, especially Agfacolor paper, as the two colour printing papers, viz: Gevacolor 8 for unmasked negatives, and Agfacolor CN III, were very similar. Gevaert suggested that the first test print should be exposed with the filters marked as “Pos Corr” (Positive Correction Filters) on the label of the packet or box of Gevacolor paper used to make the prints (for an example, see the Gevacolor M8 package photo, below). This would result in a far better colour rendering than if the user started by making test prints without the use of any printing filters, i.e. a “zero” print. The “Pos Corr” figures could also be used to calculate the new filtration when changing from one batch of Gevacolor paper to another, using the same method as when printing on Agfacolor paper (see Agfacolor section). Once a good print had been made from a well exposed, good quality negative, the same filtration, or filter “pack”, could be tried with the next negative to be printed. A complete set of Gevacolor CC printing filters comprised of 33 separate filters, 11 in each of: 'j'=jaune (yellow), 'm'=magenta and 'c'=cyan. There were 10 filters in each colour of graduated density, numbered from 10 to 100 in steps of 10 units. There was also a 5 unit filter in each colour, making 11 in total for each of the three colours. The sets of filters were very similar to the Agfacolor glass printing filters (consisting of 5 units to 99 units in each colour; see Agfacolor section). Gevacolor CC filters were obtainable

in gelatine sheets and glass filters, the latter consisting of

gelatine filters mounted between two sheets of glass in various

sizes: Filtrations were written in exactly the same way as when using Agfacolor printing filters, in the order of “Yellow, Magenta, Cyan”. A filtration of no yellow filtration, 70 units of Magenta filtration and 50 units of Cyan filtration, was written as: -- 70 50, where a line denoted a filter colour not being used. Gevaert supplied a table in which the exposure increases and decreases could be worked out by means of filter factors when changing the filtration. Corrections for Gevacolor CC filters from “5” to “200” densities were listed alongside the correction factor. For very small density changes, up to 15 units, the exposure could be altered by 10%. The correction table applied to Magenta and Cyan filters only, as exposure changes due to variations in yellow filtration could be ignored. Example 1: To the test print filtration

of -- 40 50 Add a 10 magenta filter, making – 50 50, and

add a 30 magenta filter plus a 30 cyan filter (equivalent to

adding 30 blue). The filtration 'pack' then becomes -- 80 80. To determine the exposure correction, the newly added filters had to be added together i.e. add together the 40 of Magenta and the 30 of Blue, to make 70 units. The exposure correction factor could then be read from the table. For +70 units the correction was found to be x2. Hence, the new exposure time for the new filtration of – 80 80 was 16 seconds. If the separate 70 unit filter in either magenta or cyan was added to the original filtration, ( -- 110 50, or – 50 120) the factor of x2 would apply in each case. The filter exposure factor could range from x1 i.e. no exposure time change for a 5 unit filter, to x7 for an additonal 200 units of filtration (summing the additional filters together). By comparing the Gevacolor exposure filter factors with similar factor tables for Agfacolor magenta and cyan filters, the higher value Agfacolor cyan filters were slightly denser. Agfacolor and Gevacolor magenta and lower value cyan filters were almost of the same density. This comparison applied to glass filter sets from both manufacturers. In the case of the Gevacolor filter factors, it seems the same exposure factors applied to both the Gevacolor CC gelatine and the Gevacolor CC glass filters. Example 2: By way of Example: It is found that a 60 magenta filter on it’s own corrects the colour balance of a print satisfactorily (-- 60 --). The 60 magenta glass filter is placed in the filter draw of the enlarger together with three “blanks”, three glass filters with no gelatine filter in between the glasses. Then, if a subsequent print requires that an additional filter is added, say a 40 cyan, one of the “blanks” is removed and the 40 cyan put in it’s place (making the new filter 'pack' -- 60 40). It is only then necessary to increase the exposure time for the newly added 40 cyan filter without having to consider an exposure change due to any change in the number of glasses. The point of this method was that, if the glass blank, or blanks, were not there, and the 40 cyan filter was added to the 60 magenta filter, the two glasses that contained the cyan filter would absorb some light that would not have been taken into account when using the exposure correction table for the addition of the new 40 units (cyan) filtration. Admittedly, the extra loss of light would have been small, but when making large changes to the filtration it was possible, if the user simply relied on the exposure factors given in the Gevacolor table, that the resulting colour prints would have been under exposed if changes in the number of glasses had been ignored. Example 3: By way of Example: A filtration of – 65 75 would comprise of four separate glass filters, a 60 unit magenta and a 5 unit magenta, plus and a 70 unit cyan and a 5 unit cyan. Over 40 years ago, the author used this same method of maintaining the number of blank filter glasses with a filter 'pack' when making Agfacolor prints with massive 9 inch square glass 'ICI Colour' printing filters. Additive (Tri-color) Printing Tri-colour printing required a separate exposure time through each filter in turn. Colour correction in the print was achieved by varying the exposure time through each filter, or by varying the intensity of the printing light through each filter. Darkroom Safelighting for Gevacolor Paper and

Gevacolor Positive Film 'Gevinac' darkroom safelight filters were manufactured by Gevaert in sheet sizes for other darkroom lamps. A dark yellow 'Gevinac' safelight filter, coded X592 for Gevacolor Paper and Gevacolor Positive film was for use in darkroom lamps taking rectangular glass filters. Gevacolor Paper and Positive film could also be handled under a 15 watt Sodium Safelight fitted with a 'D2' filter. No precise time was given for the handling time of Gevacolor paper and Gevacolor Positive film under any of the safelight filters. It was suggested by Gevaert that the paper or film, when handled under the safelight filters, must not show any signs of fogging for a time equivalent to the normal processing time of the Gevacolor paper. The 'normal' processing time of the paper was about 10 minutes, if the time is taken from placing the paper in the Developer to the end of the Fixing time, when the white-light could be turned on. It is probably safe to assume that Gevacolor paper and Positive Film could be handled for a maximum time of 10 minutes, with a safelight to printing material distance of about 5 feet. A

Note on Gevacolor Paper Filtrations |

|

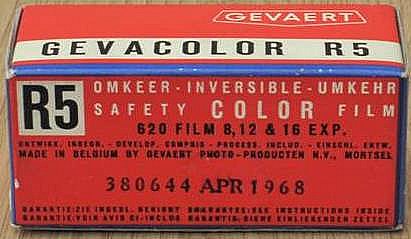

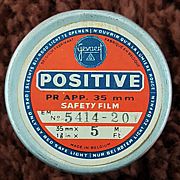

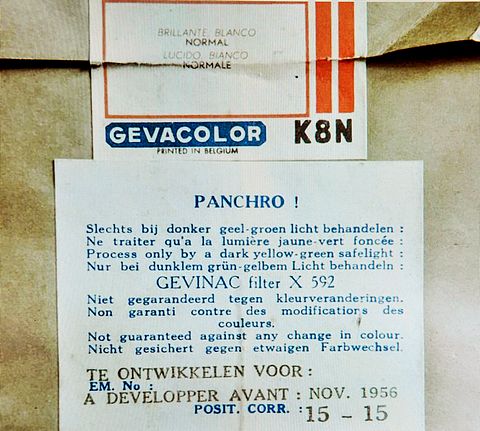

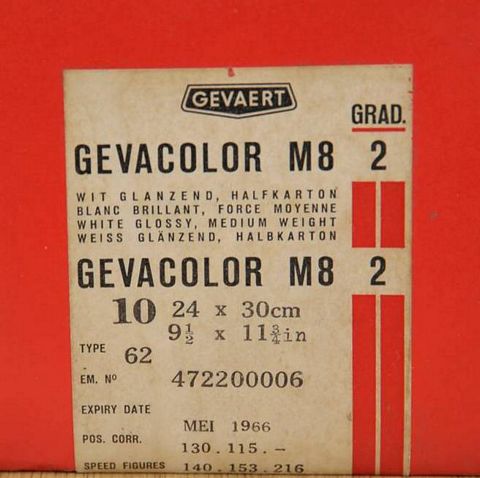

Below are shown various examples

of packaging used by Gevaert prior to its 1964 merger with Agfa

and in the few subsequent years that the Gevaert name remained

'stand-alone'. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

K = doubleweight, 8 is the Gevaert code for White Glossy surface, and N means Normal contrast grade. The expiry date, or “Develop Before” date is November 1956. It seems the 1950s Gevacolor paper was made in three grades of contrast, Code Z for Soft, code N for Normal and code V for Hard, possibly V originates from the word Vigorous. The “Positive Correction” figures are 15—15, meaning 15 yellow filtration, 0 Magenta filtration and 15 Cyan filtration. The “Positive Correction” figures were only used when changing between batches of different emulsions of printing paper. They were no use as a “starting” filtration. M8 was a normal contrast grade colour paper for printing from masked colour negative films such as “Gevacolor N5 Mask” film. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Gevacolor M8 paper was introduced in early 1963, for making prints from Gevacolor N5 Mask film. Alongside is a label from a

packet of Gevacolor M8 paper for printing from masked colour

negatives. The “Pos. Corr” figures

were for use with “White Light” printing when using

Gevacolor printing filters on an enlarger with a filter draw,

or the figures could be dialed into a colour head. The figures

were a guide as a starting filtration, or when changing from

one batch of paper to another. “Speed Figures” were used for Tri-Color Printing, and these figures related to either the Red, Green and Blue, or the Blue, Green and Red speeds of the individual layers of the paper. They were used when calculating the tri-colour exposures on automatic printing machines in D&P laboratories, or when using tri-colour filters on an enlarger when changing between batches of paper or to a paper with different emulsion numbers. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Two boxes of Gevacolor chemicals for colour print processing. The left hand box is Colour

Developer G - 21 to make 2½ litres of working

solution. The boxes date from around 1964 to 1966. There is a date of 25th May 1966 on the G - 366 box. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Gevaert Negative N5 film boxes. The two 35mm film boxes on the left, Gevacolor N5 Mask, had a speed of 40ASA (ISO). On the right is a 120 size

roll film of the unmasked variety with a speed of 25ASA (ISO).

The “Dev. Before” date is July 1959. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In 1957, four solutions were required for processing Gevacolor paper: Colour Developer; G-26 All of these were sold to make working solutions of 2.5 litres, 10 litres or 50 litres. All components in each pack were powder chemicals, with the exception of the Colour Stabilizer, where one component was a liquid, the other component being a powder. The liquid part was Formalin, similar to the Agfacolor “Stabilizer” solution. Whereas Agfa provided the powder component of its Stabilizer but required the Formalin component to be purchased separately, Gevaert provided both parts in their “Colour Stabilizer” packs. Keeping Properties of the made up solutions were specified as follows: The Developer, G-26, would

keep in a full bottles for 2 months. Processing Procedure for Gevacolor Paper, from July 1957 A safelight could be used during the first three steps if desired, either a Gevinac X592, D2 or Gevalor X591 (see above).

Total processing time : 40½ minutes. Replenishment. Colour Developer G-26. Fixer G-56. Bleaching Fixing bath G-70. Colour Stabilizer. G-61. Processing

Procedure for Gevacolor Paper, from April 1963 Safelight for first three steps (Gevinac X592, D2, or Gevalor X591).

Total processing time: 40½ minutes Notes:

Processing

Procedure for Gevacolor Paper, Shortened Process Safelight for first three steps (Gevinac X592, D2, or Gevalor X591).

Total processing time: 30 minutes Jack Coote gives some

estimates of the capacity of the solutions if used without replenishment. The very low capacity of the Fixing bath is due to leaving out the Wash step between the Developer and the Fixer; the Fixing bath becoming rapidly contaminated with Developer. In the 2nd edition of Jack Coote's book “Colour Prints”, the Stabilizer time is given as 1 minute. This is too short and is probably a printing error. In the 3rd edition of Jack Coote's book "Colour Prints" (published in May 1968 by the Focal Press) he mentions the longer 1963 Gevacolor print process. Processing Gevacolor M8 Paper using the Kodak Rapid Colour Print Processors H11L and 16K Safelight for first three steps (Gevinac X592, D2, or Gevalor X591).

Total time: 7 minutes 10 seconds to 7 minutes 40 seconds. Notes:

Personal notes by the author

on the use of this process. In 1970 I was a student at Medway College of Art, Rochester, Kent. On one occasion, when the colour darkroom lecturer was absent, I was searching the cupboards in the colour darkroom for a particular colour processing chemical to mix up. In one of the cupboards I found many unopened red boxes of Gevacolor print processing chemicals, mostly in 2½ litre sizes. A day or so later I happened to mention the Gevacolor chemicals to the colour darkroom lecturer and he told me that when he first lectured at the College there was a Gevacolor paper processing unit instead of the present Ektachrome E2 and E3 3 gallon tank line. He also said Gevacolor paper could be processed successfully on the Kodak Rapid H11L processor, which we were using at that time for Ektacolor Commercial paper. A few weeks later the darkroom was running low on the CP5 chemicals, used for Ektacolor Commercial paper. The lecturer asked me if I would like to mix some Gevacolor print processing chemicals to use instead of the Kodak CP5 chemicals. “I haven't got any Gevacolor paper”, I said to him. “Ah, but I have”, he replied, and unlocking one of the large metal cupboards standing outside the darkroom, he pointed to the top shelf where I could see at least 8 unopened red packets of 15 inch x 12 inch Gevacolor M8 paper, 10 sheets in each. We found the paper was all the same batch, with an expiry date of August 1967, possibly some of the last Gevacolor paper made. I mixed the Gevacolor developer, fixer, and bleach fix, but there was no stabilizer. I asked the lecturer if there was any stabilizer chemicals, whereupon he dived underneath the Ektachrome processing unit and grabbed a large plastic bottle which had accumulated a thick layer of dust since the last time it was used, possibly before the expiry date on the Gevacolor paper ! However the solution worked perfectly, and gave no trouble. When opening a packet of paper to cut some test strips, I found the sheets to be well wrapped in one layer of thick metal foil. It was interesting to note that by this late stage of Gevacolor paper production, the “Pos Corr” and “Speed Figures” were written on the labels in blue biro. The “Pos Corr” yellow filtration was given as 195 (see picture of Gevacolor M8 paper label above, from an earlier packet). The paper turned out to be somewhat slower in speed than Ektacolor Commercial paper, not suprising considering it’s age. Contrast was low, but not unacceptably so, and the white borders were off white, going slightly yellow. Test strips were processed up to the last wash, (Step 7), and judged for colour balance while still wet. Colour balance changes between wet and dry prints were small, the paper was slightly more red whilst wet. Colour casts were not difficult to access on the wet prints, much easier than with Kodak colour papers, and test prints were dried on the heated dryer when they were very nearly of the correct balance. The paper was not Resin Coated (i.e. not RC or PE). Pink casts on the processed

prints. With hindsight, and now having a lot more experience in colour printing, I believe the stain was caused by traces of Colour Developer finding it’s way into the Bleach Fix. At the time it was not thought to be fogging from the Safelight, although we were exposing Gevacolor paper to the light of a Kodak Wratten 10H safelight filter, suitable for Kodak colour papers. The filter colour was known as “dark amber”, a very dark orange, and if it had been safelight fog the highlight colour would have been cyan or green. It is possible that the two 5 second rinses were not long enough to wash all of the Developer chemicals out of the paper and Developer was still active in the Bleach Fix, the Fixer in between being too weak to “stop” the developer chemicals. The dish and tank process operating at 68°F recommends a wash step of 10 minutes between the Fixer and Bleach Fix. (see previous processing tables, above). Another cause may have been the age of the Gevacolor paper. Despite these problems, I remember making a few acceptable prints on Gevacolor paper, and it was interesting to have the experience of an obsolete process. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

Gevaert sold several 35mm and

roll format films in the late 1930s: Gevaert films disappeared from the UK market (perhaps also the US market) during World War 2, but were available aagain by 1947. A Gevaert advertisement in Amateur Photographer for 5th November 1947 starts by saying "Back Again.... (though in short supply through leading dealers)." !n 1947, films were Superchrom 30 (a general purpose orthochromatic roll film), Microgran 27 (ultra fine grain panchromatic, roll and 36exposure 35mm) and Panchromosa 32 (ideal for indoor work. Panchromatic and of fine grain notwithstanding its high speed, roll and 36exposure 35mm). The numbers after the film name are believed to refer to the Scheiner speed rating system, such that Microgran (presumably the same as Panchromosa Microgran) would be around 40ASA (ISO; before the 1960 speed increase), Superchrom 30 would be around 80ASA (ISO) and Panchromosa 32 would be around 125ASA (ISO). A 35mm canister of Panchromosa is shown further below. |

|

|

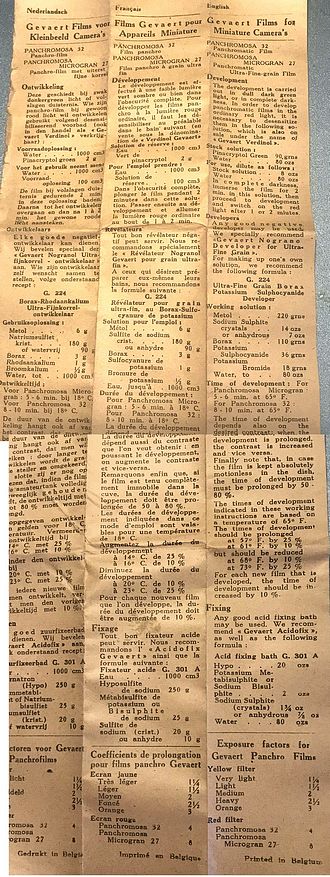

(Processing) Gevaert Films

for Miniature Cameras (original multi-language leaflet is

shown to the right) Development Exposure factors for Gevaert

Panchro Films |

|

.jpg) .jpg) Top and bottom stickers on a Gevaert black & white 35mm film cassette canister, maybe around 1950. |

Top sticker from a Gevaert

black & white positive 35mm film container. |

|

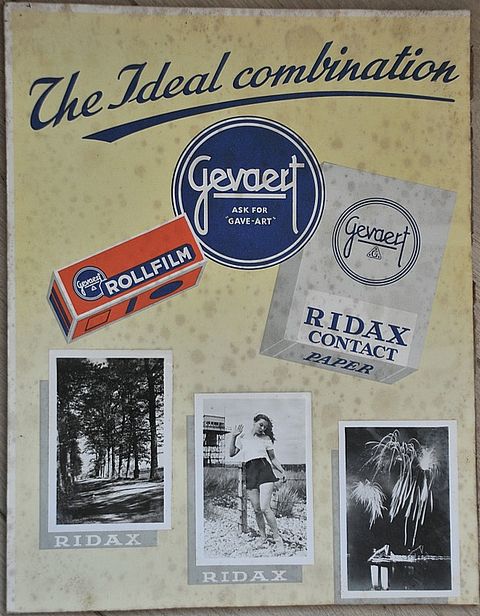

To the left is shown a Gevaert poster advertising Ridax contact paper (for making same size prints from black & white negatives). The digital image was sent to me by Adam Harras, who runs digital-watch.com, a reference site about early digital watches. Adam "knows how important it is to try to archive as much information as possible". Adam says "I havent been able to date (the advertisement) but it was behind an old 1940-50s watercolour". That date range fits with information available on this website. |

|

|

|

|

Michael Talbert started making colour prints in 1969, using Kodak Ektacolor Commercial paper. He was a photographic colour printer in the 1970s, printing colour negatives mainly onto Agfacolor paper. He also had experience using about 10 types of Kodak paper, plus other makes, Gevacolor, Fuji, Paterson, Konica. Michael now sets up and takes “Retro” fashion pictures, but prints them digitally. |

|

| Agfa-Gevaert: | |

|

“Gevaert” was a large

Belgian photographic material manufacturing company founded by

Lieven Gevaert in 1894. The company’s plant at Mortsel made

colour film and colour printing paper as from the early nineteen

fifties, initially mainly for D&P laboratories. The company

started marketing their colour film and colour printing paper

in the UK in 1953, with the sizes of prints and prices being

similar to Agfacolor at that time. Agfa and Gevaert joined forces in July 1964. Both companies continued to make colour film and colour printing paper with their own brand labeling for a year or two after 1964, and by the late 1960s film and paper products were labeled “Agfa-Gevaert.” In 1981, Agfa's 100% owners Bayer, who previously had only controlled 50% of the combined Agfa-Gevaert group, became 100% owners. |

|