| Early Agfa colour materials - researched by Michael Talbert |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Agfa Farben Platen; Agfa Color Plates |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Alongside is shown a box of four Agfa Color Plates dating from the 1920s which, when processed by a black and white reversal process, produced a colour transparency. Three separate gum solutions, one dyed red, another green and a third blue, were thoroughly mixed together to form a grey solution which was then coated onto glass. This dried to form a layer of exceedingly minute transparent dots of the three colours. The red, green and blue dots were more or less evenly spaced so no colour was in excess of another. A panchromatic emulsion was then coated on top of the coloured gum layer to make a close contact. The plates were exposed in the camera with the glass side towards the lens so that the light passed through the transparent coloured dye gum layer before reaching the panchromatic emulsion. Each transparent gum dot acted as a colour filter. The plates were very similar to the Lumiere Autochrome plates (or Dufaycolor) and the gum grains were almost the same size as the Autochrome plate starch grains. These plates are the second type of Agfa Color plates, known as 'New Agfa Color' plates, manufactured between 1923 and 1932. They have a 'Develop Before' date of February 1930 stamped onto the box. The first Agfa Color plates were manufactured in 1916 and the last 'Color' plates, named 'Agfa Ultra Color' plates, were introduced in 1936. They were replaced two years later by Agfacolor Neu film. A box of four plates of this size, 2½ x 3½ inches, cost 4 shillings and 3 old pence in May 1934, (about 22p in decimal currency, though approaching £20 in 2024), and this price did not include the processing costs. The British Journal Photographic Almanac gave good advice about exposure: “As a guide to exposure, the plate may be given 30 times the exposure required by an extra rapid ordinary plate of about 250 H & D”. These plates may have been twice the speed of the earlier 1916 to 1923 plates, as the box has a sticker in the top left hand corner - “ Caution – Double Sensitiveness”. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(H & D stood for Hurter and Driffield, one of the first speed systems for glass plates from the 1890s. An ordinary plate meant that the plate was blue sensitive, sensitive to blue and white light only. 250 H & D is approximately 8 ISO/ASA. Hence, an exposure of 30 times an exposure given to a plate of 8 ISO/ASA, means the Agfa Color plate would have a speed of very approximately 0.25 ISO/ASA!). References: Colour Photography, F.Newens, 1931. British Journal Photographic Almanac 1931. Twentieth Century Color Photographs, S.Penichon, 2013. Agfa Price list, Photographic Supplies, May 1934. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor

Ultra (additive) and Neu (subtractive) Reversal Films There were two types of Agfacolor additive 'reseau' films. One, Agfa Color Film, dates from 1932, and the other, Agfacolor Ultra, a faster film, dates from 1934. Both these films were derived from Agfa Color glass plates, which were sold in Germany as long ago as 1916. Agfa did manufacture a 35mm film in 1933, but this was a Lenticular film, specifically for Leica cameras. The film had minute lenses incorporated into the film base, and transparencies were viewed with a Leitz projector fitted with a three band colour filter. The process was mainly used for cinematography and saw little use in still photography. It was similar to the earliest 'Kodacolor', a 16mm version for home movies made by Kodak in 1928.

Agfacolor Neu film could be purchased in Germany from 1936 and it is likely that Agfa had a processing laboratory in Berlin. As far as the author has been able to ascertain, the film price included the cost of processing. There was an address for Agfa in Berlin in the 1930s: I.G. FarbenIndustrie Aktiengesellschaft / Agfa, Berlin SO 36. But Saskia Bormann has e-mailed (December 2014) from Braunschweig (home of Rollei and Voigtländer) to tell me that Berlin SO 36 is not an exact address. It's short for Süd-Ost (South East) + the number of its post office (in this case 36), which relates to a whole city district, mainly Kreuzberg. It is possible that the price of the film was subsidized by the Nazi government in the late 1930s, paid for by wage freezes and higher taxes, thus making the film an affordable purchase for the average German worker. The film was also known as “Agfacolor 111”. Agfacolor Neu film was sold in the UK before World War 2. The price of a 36 exposure cassette of Agfacolor Neu 35mm film in 1937 was 6 shillings (30p), and this cost included the processing. Kodachrome film was much more expensive. The price of an 18 exposure cassette of Kodachrome 35mm film, including processing, in 1937, was 12 shillings and sixpence (about 62p). Kodachrome film at that time was available in Regular (Daylight type) and Type A (for Photoflood lighting). Agfacolor Neu film was then available in Daylight type only. However, the British Journal Photographic Almanac (BJPA) for 1939 reported, in it’s 'New Goods' section, on an Agfacolor 35mm Artificial light film. Also, by 1938, the speed of the Daylight type film had been increased from 17 Scheiner (4 ISO/ASA) to 25 Scheiner (25 ISO/ASA). Agfa advised using this rating for 'light subjects', while the speed should be decreased to 21 or 22 Scheiner (10 or 12 ISO/ASA) for shaded and dark subjects. The artificial light film had

approximately the same speed, and was balanced for Photoflood

illumination, (3400K.) Filters (colour balancing filters?) could

also be supplied by Agfa for use with 'Flashlights'. A test was

made using a single Photoflood lamp at an exposure of 1/15 at

F/3 at 3 feet from the subject. The “colour rendering is

very pleasing indeed”. It is reported that the colour balance

of the film turns blue with under exposure but over exposure

“results only in a slight added warmth of rendering which

is not at all unpleasing”. The 'Westminster Annual of Photographic Accessories' for 1939 included two Agfacolor films for sale, viz. Agfacolor Film in 36 exposure 35mm cassettes priced at 6/- (6 shillings = 30p) each and Agfacolor Film in 12 exposure “Karat” cassettes priced at 3/6 (3 shillings and sixpence= 17p) each (prices in mid-1939). The 'Westminster Annual' informed us “All Agfacolor prices include processing. When ordering, specify Daylight or Artificial light.” When the Agfa processing plant in the UK shut down in 1939, there was still a considerable amount of unexposed unsold Agfacolor Neu film in the camera shops and photographic dealers stocks. Some enterprising amateur photographers, who also had some knowledge of photographic chemistry, made up their own processing solutions for processing Agfacolor Neu film, gaining information from Agfa patents. Sometimes the processing formulae were published in various U.K. photographic magazines. Below is a genuine Agfa processing sequence for Agfacolor Neu film, dating from 1945:

It was likely that the processing temperature was about 64°F, 18°C. The Intermediate bath (step 3) was a rinse in Wetting Agent to ensure that water flowed off the film evenly leaving no “tear” marks. Marks left on the film during the Re-Exposure (step 4) sometimes caused stains when the film was colour developed. As far as the author knows, there was no “Stabilizer”, or “Anti-Fade" bath before final drying (step 13). Wilhelm Lange, an archivist at the National Archives of Norway, department of private archives, was recentley (February 2012) given a collection of pre-war photographs. He says "94 of these are colour slides, many taken in Berlin on May 1 1937, the rest mainly summer holiday photos from Norway from the same year. These are the oldest colour photographs that the National Archives own. The Agfacolor Neu colour slide pictures are in the Thomas Neumann archive: http://www.flickr.com/photos/national_archives_of_norway/sets/72157629888217042/ with English text. Some of the texts may be inaccurate. "A selection of the photographs was printed out in large format and displayed in our vestibule. For the opening we had a historian to comment on facts behind the photos for a small crowd of invited people and others who dropped by. Among them were Neumann’s daughter who was born after the war and knew very little about her father’s early political exploits. Also a son and daughter of J.B. Hjort came – the man who was really in the centre of developing the Norwegian National-Socialist party from 1933, but was kicked out with Neumann in 1937. Like many children, the Hjort children were in opposition to their father’s politics – she to the point that she was later given a knighthood for her war-time activities." Agfacolor

Motion Picture Negative Films, Types B & B2 and G & G2,

1939 to 1945 Note: There was film for Motion pictures called SOVCOLOR, made after the war (1945 -54), in the Russian sector of Berlin at the Agfa factory at Wolfen. Seemingly it was a Type G colour negative film, rated at 13 /10 DIN, which makes it about 12 ASA.

A multi-layer colour coupler type negative film (type B balanced for daylight and type G balanced for artificial light), were announced by Agfa (probably to the German film industry, U.F.A; for a Wikipedia definition see below) in 1937. It was a 35mm film, designed for motion picture use, as the German Film industry already had much experience in, and the necessary equipment for, processing and printing large quantities of 35mm black and white film to a high standard. The first colour prints to be made from a multi-layer colour development negative film were printed onto an equivalent positive film, not paper. This positive (print) film was announced at the same time as the negative film stock. These negative & positive films were not manufactured in any quantity until 1939. The negative and positive films were certainly not on sale to the German public. At the beginning of W.W.2, U.F.A. and other film studios in Germany were instructed by the German Propaganda Ministry, (Joseph Goebbels), to make several full length feature films using the new Agfacolor negative / positive films. At that time U.F.A. did not consider the new Agfacolor films were sufficiently technically advanced to do this, but they went ahead and made about 13 films, (some unfinished) during the war to 1945. Two types of negative film were available, Type B for daylight, type G for artificial light. The films were processed and printed using modified black and white equipment but owing to wartime conditions, some of the release prints were inferior. It was generally agreed that “Die Fledermous” showed the best colour quality. The processing procedure for Agfacolor negative film changed little over the next 30 years. After 1940, all research and development was done under the approval of the German Government. Some work was carried out on a special soft gradation reversal film for the production of duplicate negatives (negatives from negatives), but the film was only used for the duplication of short sections, spliced in with the original colour negative. In all cases, the original colour negative film which had been exposed in the camera and suitably edited, was used to make the release prints, and no duplicate negatives were ever made for the printing of a complete film. A number of the feature films made were never released to German audiences, either because the films were never completed by 1945, or were considered unsuitable for showing to the German public. The Agfacolor Motion Picture Negative films were panchromatic films coated with three emulsion layers, one sensitive to red light, one to green light, and one to blue light. Originally, when the negative films were first manufactured in 1939, the film speed was 10/10 degrees DIN, corresponding to about 6 ASA (ISO). A year later, one source claims this speed had increased to 16/10 degrees DIN, or roughly 25 ASA (ISO). As far as Michael has been able to find out, this claimed high speed applied to both types of film. However, another source states that, in 1945, the film speed was 14/10 degrees DIN, around 12 to 16 ASA (ISO). This is much more likely to be true, as this corresponds to the speed of the Agfacolor Negative films for still photography, CNT and CNK, introduced in 1949. The Agfacolor Motion Picture Negative films were similar in structure to the very early Kodacolor films, but Agfacolor film employed a different type of colour coupler. The Red sensitive emulsion layer was coated on top of the Nitrate base of the film. This layer contained the Cyan dye coupler which, on development, produced a negative cyan dye image in the exposed areas. A Green sensitive emulsion layer was coated on top of the red layer, incorporating a Magenta dye coupler, producing a negative magenta dye image on development. Because both the red and green emulsions were also sensitive to blue light, a yellow filter layer was coated on top of the green layer, preventing any blue light from reaching the bottom two emulsions. The final emulsion to be coated on the film was the Blue sensitive layer on top of the yellow filter. This contained a Yellow coupler, which on development, produced a negative yellow dye image. An anti-halation backing was applied to the base of the film containing a blue-green dye. The backing dissolved in the development step. The Nitrate film base, which was not “Safety Film”, was the same base as used for black and white motion picture films. The yellow filter layer consisted of colloidal silver in gelatin, which was removed from the film in the Bleach bath in the processing sequence. The red and green sensitive layers each consisted of a similar emulsion to the Agfa black and white film, Isopan F. The Isopan F film was a black and white panchromatic negative film with a speed of 40 ASA (ISO). The blue sensitive layer was a positive film emulsion, sensitized for blue light only, not panchromatic. No masking layers were incorporated in the negative films, nor did the colour couplers generate a coloured mask. No form of masking for contrast correction was ever used in the printing of the negative film. As far as Michael Talbert has been able to ascertain, the exposure latitude of the Agfacolor Negative Motion Picture film was about one stop, although this is very likely to mean one stop over-exposure. Over-exposed negatives would require increased printing time. Under exposed negatives caused thin shadows with no detail, low contrast, and poor blacks in the positive release prints. Processing

Agfacolor Motion Picture Negative Film Approximate Processing Procedure for Agfacolor Motion Picture Negative Film.

Agfacolor

Positive Motion Picture Film The structure of the film was similar to the Agfacolor negative film, having the same layer order. The bottom two layers were each made up of an ”Isopan F” film emulsion plus a Process film emulsion. (At that time, Process film was a slow speed blue sensitive film of fairly high contrast, mainly for use in Graphic Arts or for copying.) The top layer was a black and white Process film type of emulsion, sensitive to blue light, i.e. not panchromatic. More variation in manufacture was allowed for the Agfacolor positive film and batch variations of up to one stop in speed were permissible. The different colour characteristics of each batch could be filtered to a neutral balance when printing. All Agfacolor film, negative and positive, was manufactured at the Agfa Wolfen factory. Processing

Agfacolor Motion Picture Positive Film Two processing procedures were necessary, one for Motion Picture Film with no sound track and the other for Motion Picture Film with an optical sound track. Magnetic sound tracks were not invented until 1953.

Notes.

During 1944/45 Agfacolor Motion Picture film was being processed at the UFA laboratories at Kopenick, South Eastern Berlin. After 1945, it was included in the Soviet sector of East Berlin. Processing and printing was also carried out at the UFA studios at Neu Babelsberg, then the capital city of the German state of Brandenberg. Most of the feature films using Agfacolor materials during WWII were produced at the UFA Neu Babelsberg studios. Printing

Agfacolor Negative Motion Picture Film onto Motion Picture Positive

Film

Agfacolor

Printing Filters for Colour Correction The purpose of the coloured filters was to change the colour of the printing light to correct for any tints or colour casts in the positive print, this being a transparent print on 35mm positive film. The filters were made in different depths or densities of colour. The highest density filter in each colour was numbered 100 strength, and the other filters were numbered in densities of 10, decreasing from 100, the lowest density being 10. Therefore a “set” of colour filters would consist of 10,20, 30, 40, etc Yellow in increasing strength up to 100, 10 Magenta in the same values, and 10 Blue-Green, in the same values. The whole set comprised of 30 filters. The value of the filters could be added together, 160 Magenta would be made up as, 100, 50 and 10. Obviously, when printing on a large scale, it was very important to keep records of the filtrations used when printing each batch of negative film. A simple system of designation was used to indicate the filter combination of any print. All filter combinations, using numbered values, were written in the order of Yellow, Magenta, Blue-green (Cyan). This sequence was chosen as it related to the same sequence as the order of the layers coated on Agfacolor negative film. A filter correction of a 70 strength Yellow filter and a 40 strength Magenta filter with no Blue-Green filters was written as 70 40 00. A filter correction of a 30 strength Magenta filter and a 60 strength Blue-Green filter and no Yellow filters was written 00 30 60. One filter could be used on it’s own, so e.g. a 50 strength Magenta filter would be written 00 50 00. There was no need for all three filters to be used as a correction because three filters superimposed on top of one another would make a neutral density or grey. In other words, if all three colour filters were of the same strength, they would cancel each other out and would not alter the colour of the print. A filter combination of 20 Yellow, 50 Magenta and 70 Blue-Green, would contain 20 “neutral density”. Therefore, if a value of 20 was subtracted from each filter the Yellow value would become 00 and this would cancel out the neutral density, or “grey” value, leaving a filter combination of 00 30 50. The colour correction filters were stapled over the paper ribbon aperture holes to adjust the colour balance and produce a neutral print. Residual colour casts in the printed, positive, film were removed by using a filter over the projection light source. In this case, the filter would be the same colour as the colour cast. If a print appeared too Yellow, or Magenta, or Blue-Green, it was corrected by placing a Yellow filter, or a Magenta filter, or a Blue-Green filter in the light source. A strong colour cast, one which could be seen very easily, was corrected by an equally strong filter value, such as an 80 filter. A very slight tint which might not be noticed was filtered out by a weak coloured filter, such as a 10 value. Red, Green and Blue casts were dealt with by combining Yellow plus Magenta to make a Red filter, Yellow and Blue-Green to make a Green filter and Magenta and Blue-Green to make a Blue filter. When printing the Colour Negative Motion Picture film onto the corresponding Positive film several test prints were made to find out the correct combination of printing filters which give the best colour rendering. Usually, “coarse” test prints were made with exposure variations and filter values of 30 units apart. A “coarse” test print would take into account any estimated casts of almost any colour. The strength of the filters used were from 30 to 90 in Yellow, Magenta, Blue-Green, Red, Green, and Blue; Red, Green and Blue being a combination of filters, as explained above. From this wide range of test printing a fairly good indication of the correct colour balance could be estimated. If the best colour in the “coarse“ test prints was estimated to be a print with the filters 00 60 60, (no Yellow filters, 60 Magenta filters, 60 Blue-Green filters), and this test print had a Magenta colour cast of, say, 20 units, another test print was exposed with the filter combination 00 80 60; i.e the Magenta value was increased to 80 to correct for the magenta colour cast in the 'coarse' print. Other test prints were also exposed at the same time varying the filtrations by say, 10 or 20 units around 00 80 60 (00 80 80, 00 80 70, 00 70 50, and so on). This series of test prints would “fine tune” the colour to hopefully arrive at an optimum colour balance and, with it, an optimum filtration value which could be used to make numerous release film prints. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor

Positive Films for Still Photography ~ 1950 In 1950 Agfacolor Positive film was introduced, for making colour transparencies directly from Agfacolor negative films. It was obtainable in 35mm lengths of 10, 25, and 50 metres and unperforated widths of 2.34 inches in 15 metre lengths. For making enlarged colour transparencies from Agfacolor negatives the Colour Positive film was available in quantities of 10 and 100 sheets of flat film in various sizes similar to Agfacolor paper CN 111. The film was balanced for exposure to 3200°K lamps. An enlarger fitted with a filter draw or an Agfacolor Head could be used to expose the film, altering the colour balance of the transparency by means of separate colour printing filters or the Agfacolor Head, in the same way as when making colour prints on Agfacolor Paper. The film could be handled for about 3 minutes under a safelight fitted with an Agfacolor Safelight filter No.166. The film was said to be around twice as fast to light as the CN 111 paper and handling the film for too long under the safelight caused a blue-green cast, mainly in the high lights of the transparency. In the early 1950s, Agfacolor Mosaic filters could be used to find the correct colour balance in exactly the same way as printing onto Agfacolor paper. Agfacolor Positive Film Processing

Notes.

By 1954, a “Bleaching-Fixing” Bath took the place of the negative film separate Bleach and Fixer solutions. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor

Positive Film S This sequence for processing

Positive Film S dates from around 1954.

Notes.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

At the end of the 1950s, the above processing sequence changed slightly. The development time was now given as 4 to 10 minutes, allowing some alteration in the contrast of the transparencies, and an additional “Agepon” rinse completed the sequence. The following processing sequence for Positive Film S dates from 1958.

Notes.

A further processing sequence for Positive Film S dating from 1962 with minor changes

Notes.

Agfacolor

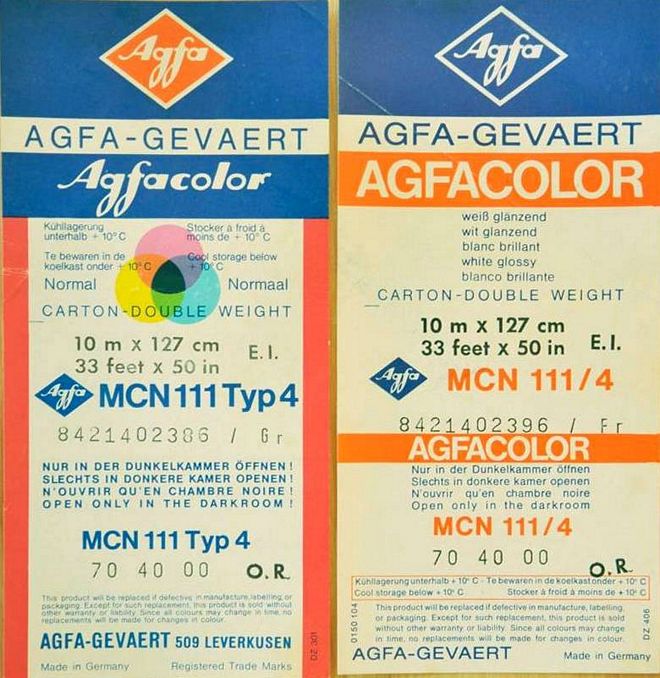

Positive Film M The sensitivity of Positive Film M was similar to Agfacolor MCN III paper, having a very high sensitivity to blue light and an increased sensitivity to green light, compared with Positive Film S or Agfacolor paper CN III. It could be handled for a limited time under the Agfacolor Safelight filter No.166M, later known as Agfacolor Safelight filter No.08. Positive Film M could be processed in exactly the same sequence as Positive Film S, following the 1962 processing sequence (above). In the mid 1960s, Positive Film M replaced Positive Film S, and by 1967 Positive Film S was no longer available. A 1971 processing sequence, printed within the instruction sheet for Positive Film M that was enclosed in the film boxes, gave 8 minutes as the standard development time at 68°F +/- 0.4°F. The time of development could be altered from 6 minutes to 10 minutes for changes in brilliance and contrast. On a personal note, the author

made some transparencies on Positive Film M in 1975. He does

remember that compared with Agfacolor MCN III type 4 paper (being

the paper in use at that time), the Positive film was extremely

slow and occasional very large transparencies required exposure

times of over one minute. The base of the film was very thick,

much thicker than Kodak Ektacolor Print film, which made it difficult

to handle in the dark. Positive Film M had a slightly shorter

processing time of 47 minutes, compared with Ektacolor Print

Film's time of 50 minutes. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor Print Film and Printfilm No safelight conditions are given, but it is said the film “should only be exposed very briefly to darkroom lighting”. At that time, MCN111 Type 7 paper could be exposed directly to an Agfa 08 safelight screen for no longer than three minutes. It is therefore assumed that Agfacolor Print Film could be handled under the same safelight conditions. Under the section on “Processing”, is said: “In order to allow the shortest possible processing times, Agfacolor Print Film has been balanced to enable processing in the solutions used for paper”. No processing sequence is given. Apart from this short one page chapter of information where no safelight number or processing data is mentioned, the author was unable to find any further information on Agfacolor Print Film. It is not included in the “Agfacolor” book by Heinz Berger (German edition) published in 1972. A 16 page insert enclosed in the book, “Erganzungen Januar 1976” (supplement January 1976), mentions only “Agfacolor Positive Film M” (see section above). Two more editions, 1975 and 1977, of “Agfacolor User Processing – the negative positive process” contain no information concerning Agfacolor Print Film or Positive Film M. From 1972 to 1977 it is not clear whether Agfacolor Print Film was intended to be a replacement for Positive Film M or if both materials were available for sale. Since Positive Film M in all formats could be processed through the same chemicals as Agfacolor papers by 1968 (MCN111 in 1968) and it is reasonable to assume the new Print Film would follow the same procedure. Even by the end of 1975, the chemicals listed for use with Positive Film M were still the same chemical baths that had been used to process MCN111 Type 4 and the old Type 7 papers, i.e the “P.A. four bath process”. PE Agfacolor papers (polyethelene) were, by 1975, being processed in a three bath process with much shorter processing times. A price list for Agfa Gevaert Professional Products dated February 1978 included Agfacolor Printfilm (note: Printfilm not Print Film) for sale in various sheet film sizes, 35mm, and one roll size. It was described in the price list thus: “Agfacolor Printfilm is a new generation of positive colour film for the production of colour transparencies from colour negatives, for display, projection or reproduction”. Available in sizes 4 x 5 inch, 8 x 10 inch and 22 x 27 inch, plus six centimetre sizes, 35mm and a 105 cms wide roll size, for making “mural” transparencies. It should be noted that the largest sheet size was identical to the largest sheet size obtainable in Agfacolor MCN Type 4 paper. One sheet could be cut into nine sheets of 9 x 11 inches, suitable for making 10 x 8 inch transparencies with a large border for attaching to a plastic blanket, or onto rods, on a large processing machine. Three bath processing was given as Process 81 for roller transport machines or Process 85 or Process 86 at 24°C. The powder type Colour Developer 82 could also be used. Positive Film M is not listed in the Agfa Gevaert Professional Price list for February 1978, so it is assumed that the, then, new Agfacolor Printfilm replaced Positive Film M by 1978 or even a year or so before. According to a Professional Price List for March 1980, the 35mm size and two of the centimetre sheet sizes of Printfilm were by then no longer available. Processing Sequence for Agfacolor Print Film, Positive Film M and Positive Flat Film M, from 1972

Total time: 34½ minutes. Notes:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High Temperature Process for Agfacolor Print Film, Positive Film M and Positive Flat Film M

Total time: 25½ minutes. Notes: The Wetting Agent Rinse consisted of 5ccs wetting agent to 1 litre of water plus 15ccs of 30% formalin. The wetting agent used was normally Agfa Agepon. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

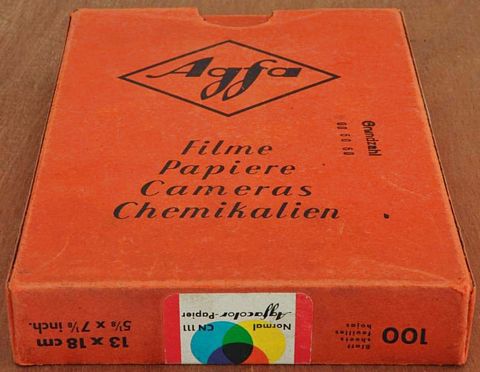

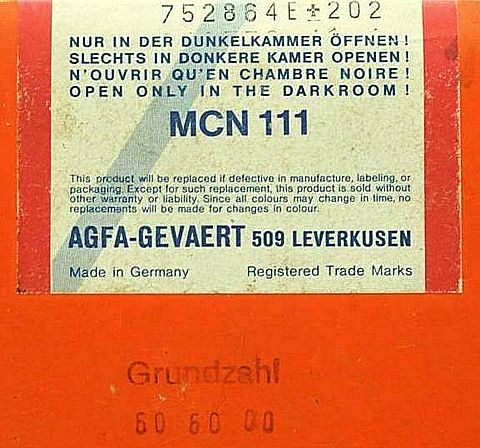

Box of Agfacolor Print

Film, illustrated below. The very high yellow filtration is not a misprint! Two other boxes of Agfacolor Print Film have been seen to have filtrations of 155 45 –- and 160 65 --. Both boxes were of much later batch numbers. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

dating from 1972 – 73. |

The rear label (see right) gives just a brief description of the film. Later labels carried a diagram of the “code notch”, a semi circle. It is odd that no expiry date or “develop before” date is printed anywhere on the box, therefore the manufacturing date is difficult to determine. 1972 or 1973 is a 'best guess'. This is a strange box of film as there is no information about the film after the 'Agfacolor User Processing' book first edition. Positive Film M could be processed in print processing chemicals by 1972, but when the author worked in London, the processing lab (1974) used Positive Film M processed in the old sequence of chemicals, taking about 48 minutes processing time with the “Special After Bath”. It definitely wasn't Agfacolor Print Film, as the author remembers that the film came packed in orange boxes. The 'CPL' laboratory made their large transparencies on Kodak Ektacolor Print or Ektacolor Slide film. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In the early years of World War II, much experimental work was done by Agfa on a process for making colour prints on paper. By 1942, Agfacolor Paper was available for making prints from Agfacolor negative motion picture film. It was originally decided by Agfa to release the negative/positive process to the general public as soon as World War II was over in Europe. But in 1945, production of film and paper had ceased at the Wolfen plant because of lack of basic raw materials and the collapse of Germany. Also, by then, the patents for the Agfacolor process became available to other photographic material manufacturers, such as Gevaert and Ferrania. Later on, both companies marketed colour negative/positive processes very similar to Agfacolor. The experimental paper, and some quantities of it, were originally made at Wolfen, but by 1949, both film and paper production had moved to Agfa’s Leverkusen plant, although Wolfen, later known as Orwo, continued to make colour film (and some paper). In January 1949, Agfacolor film was made available to the general public, and the first colour processing laboratories for processing and printing Agfacolor negative film were set up in Germany. As far as Michael Talbert is aware, Agfacolor negative film was first sold in the U.K. in July 1951. By June 1951, four processing laboratories had been established in the U.K. At that time, Kodacolor film was not sold in the U.K; the only Kodak film obtainable to the amateur photographer was the transparency slide and movie film called Kodachrome. Ektachrome film was accessible to the professional photographer in limited quantities. Colour prints could be made by the “assembly” processes, such as Kodak Dye Transfer, Trichrome Carbro, or Duxochrome. Prints from these processes were very costly and were used mainly by professional advertising photographers, not by amateur photographers. A letter in the 'Reader's Write' column of Amateur Photographer magazine, dated 5th July 1950 (hence before the film arrived in the UK), shows how the arrival of this new type of film was greeted with some scepticism and cynicism. Possibly not helped by its Germanic origins so close to the end of WW2. "Colour in Germany".

Mr.M.M.MacKenzie wrote: Snags, however, are great, and not the least of these is the price. The cost of a 36-exposure 35-mm film developed and enlarged to postcard (all done by the trade under Agfa at the moment with a specially fitted enlarger) is DM 168.00 (post-war German Marks = £14). In words, "Fourteen Pounds!" Also, in enlarging, to find the correct rendering of the natural colours, quite irrespective of how the film has been exposed, the operator must find the correct combination of 30 filters, 10 each of red, blue and yellow. This is an 1160 to 1 shot. I know this seems impossible, but it is simplified to an extent with a very clever chart. The development time for a film is one hour and for paper, half of that, both of course 3-bath developments. So after having made seven or eight test strips, one might be inclined to feel rather brassed off. The negatives, like the usual colour transparencies, are grainless, and may also be used for black-and-white positives, so may I pass on a tip which will solve all your grain problems but at how much per film? I haven't tried this or any

other colour process, but the information is from a professional

friend of mine who has been on the Agfa course and it is authentic.

Me, I stick to black and white". Some comment on the above

letter: Mr.MacKenzie refers to the development time for a film, possibly meaning the whole of the processing sequence for an Agfacolor negative film. The actual time was 56 to 66 minutes not including the Magnesium Sulphate bath. Print processing was longer than his suggested "half an hour", but was almost exactly 30 minutes without the final wash step. The total time for print processing was actually 50 to 60 minutes. The negative process was a three-bath, but the 1950 print process included a Stop Bath named "Unterbrecherbad" ("Interrupter bath"). At that time, there was no "Anti Fade" bath. The Agfacolor negatives would have shown very little grain when enlarged to make black and white prints, partly because of the low speed (10-12 ASA/ISO, see below) of the material. The negatives would not have been entirely "grainless", as the coloured dyes in the film would have shown a type of fine grain when enlarged considerably onto a glossy black and white paper. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor

Negative Film Type T It’s speed was 10 to 12 ASA(ISO) and it was recommended to find the correct exposure with an exposure meter; in 1951, the Agfa meter was the Lucimeter. The instruction sheet for Agfacolor Type T film suggests making three exposures of the same subject, one at the exposure setting given by the meter, then one exposure at one stop less than the meter reading, and another at one stop more than the meter reading. The best exposure was then selected and with it the correct film speed for that particular camera/exposure meter combination. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

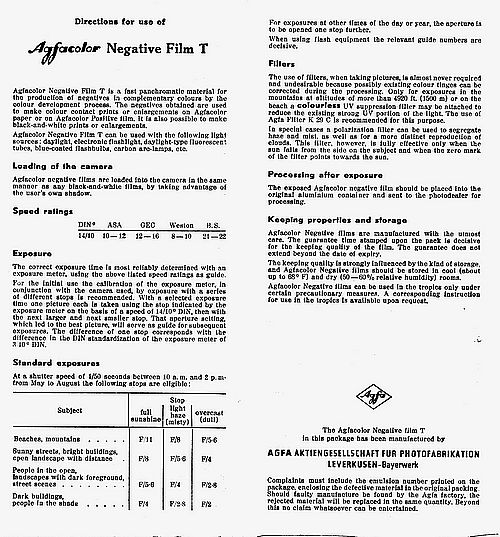

Alongside here is an original instruction leaflet for Agfacolor Negative film Type T, for exposure in daylight. The leaflet would have been enclosed in the film box and dates from 1951. The same instructions are printed in German on the other side of the paper, and it seems the leaflet may have had more translations on sections now removed. The instructions read: Directions for use of Agfacolor

Negative Film T: Agfacolor

Negative Film T is a fast panchromatic material for the production

of negatives in complementary colours by the colour development

process. The negatives obtained are and to make colour contact

prints or enlargements on Agfacolor paper or on Agfacolor Positive

Film. It is also possible to make black-and-white prints or enlargements. Loading of the Camera: Agfacolor negative films are loaded into the camera in the same manner as any black-and-white fllm, by taking advantage of the users own shadow. Speed ratings

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Exposure: The correct exposure tlme is most reliably determined with an exposure meter, using the above listed speed ratings as a guide. For the initial use the calibration of the exposure meter is recommended, in conjunction with the camera used, by making exposures with a series of different stops. One picture is taken with the stop indicated by the exposure meter on the basis of a speed of 14/10 DIN. Then take further pictures with the next larger and the next smaller stop. That aperture setting which led to the best picture, will serve as a guide for subsequent exposures. The difference of one stop corresponds with the difference in the DIN standardization of the exposure meter of 3/10 DIN. Standard exposures: At a shutter speed of 1/50th second

between 10am and 2pm, from May to August, the following stops

are eligible:

For exposures at other times of the day or year, the aperture is to be opened one stop further. When using flash equipment the relevant guide numbers are decisive. Filters: The use of filters, when taking pictures,

is almost never required and is undesirable because possibly

existing colour tinges can be corrected during the processing.

Only for exposures In the mountains at altitudes of more than

4920 ft (1500m) or on the beach a colourless UV suppression filler

may be attached to reduce the existing strong UV portion of the

light. The use of Agfa Kilter K 29 C Is recommended for this

purpose. Processing after exposure: The exposed Agfacolor negative film should be placed Into the original aluminium container and sent to the pbotodealer for processing. Keeping properties and storage:Agfacolor Negative fllms are manufactured with the utmost care. The guarantee time stamped upon the puck is decisive for the keeping quality of the film. The guarantee does not extend beyond the date of expiry. The keeping quality is strongly influenced by the kind of storage and Agfacolur Negative fllm should be stored in cool (about up to 68°F) and dry (50-60% relative humidity) rooms. Agfacolor Negative films can be used in the tropics only under certain precautionary measures. Corresponding instructions for use in the tropics are available upon request. The Agfacolor Negative film

T in this package has been manufactured by: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Un-masked

Agfacolor negatives The emulsion number printed on the rebate is 674. It is thought that these negatives were exposed pre-1956. In 1956 Agfacolor CN-17 colour negative film was introduced (see lower), and the processed negatives took on a more greenish yellow appearance. As far as possible the scanned images have been matched to the original negatives for colour and contrast, but they are not exact reproductions. Agfacolor CNT Daylight Type film and Agfacolor CNK Artificial Light Type film were first sold in the UK in 1951. These Agfacolor negatives are

un-masked, and their visible magenta cast, especially prominent

in the sky of the left hand negative, and overall in the right

hand negative, is due to the negative dyes used to form the image.

Ideally: These three emulsions must

record the primary colours in their correct proportion (i.e.

in the proportions of the original scene). Colour negatives do not have to look “visually correct”, unlike a colour transparency, so to improve on the colour balance of the print, the 'light colour' absorption maximum of the three dyes were separated as much as possible to prevent them overlapping. Hence, the absorption maximum of the yellow dye was placed in the ultra-violet region of the spectrum and the absorption maximum of the cyan dye was placed in the infra-red region of the spectrum. As the human eye cannot perceive ultra-violet or infra red light, the magenta dye in the negative is visually prominent. Thus Agfa colour negatives (from that time) look magenta. The printing materials at that time, Agfacolor CN III and CH III papers (also Agfacolor Positive film), were sensitized to ultra-violet light, green light, and infra-red light; therefore, the printing materials could “see” the yellow and cyan colours in the negative that were invisible to the human eye and reproduced them as visible colours in the final prints. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) .jpg) |

.jpg) .jpg) |

.jpg) .jpg) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor

Negative Film Type K Film speed was 10 to 12 ASA(ISO). With two lamps 4 feet away from the subject, exposures were around 1 second at f5.6. Pictures could also be taken under ordinary room lights, at exposure times of about 3 seconds at f4. It was not possible to achieve a neutral balanced print with daylight and tungsten lighting illuminating the same subject, and prints made from negatives made in this way showed varying blue to yellow colour casts on the same print. Colour filters were not recommended when exposing either type of negative film with the exception of an almost colourless Ultra Violet (UV) filter, Agfa No.K29C. Colour casts due to varying colour temperatures of the lighting were corrected by printing filters and no colour compensating filters, such as the Kodak range of Light Balancing filters, or other makes, were advised. Film

Sizes Available

Flat film was also made in

Type K artificial light film, but its unknown whether Type K

film was marketed in any other format. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor

Negative Film Processing Type T and K Only three solutions were used to process Agfacolor negative film – Colour developer, Bleach, and Fixer. When freshly mixed, the colour developer could not be used for 12 hours, as the chemicals were possibly too active and would produce negatives with too much contrast if used immediately. The three processing solutions were sold in packages to make either 1 litre or 35 litres of solution when made up.

Notes

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Agfacolor CN 17 Universal Colour Negative Film ~ 1956 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A new Agfacolor Negative film, CN 17 was introduced in 1956. This film replaced the earlier Agfacolor types T and K films (see above). It was a 'Universal' film i.e. it was balanced for use both in daylight and also artificial light, corresponding to a colour temperatures range from about 2500°K to 6500°K, but not to lighting that was a mixed colour temperature. It was possible to expose the film by the light of blue or clear flashbulbs, daylight, photoflood, or tungsten light. The resulting different colour balance in the negatives, caused by these different types of lighting, was corrected during the printing stage. Agfacolor CN 17 Universal film was first sold in rollfilm sizes 120, 620 (see picture to the left), 127, “Karat” cassettes of 12 exposures, and 35mm cassettes of 20 exposures. Later, 35mm cassettes of 12 and 36 exposures were available. Many sizes of sheet film were obtainable, including a 4inch by 5inch format (see picture to the right). CN 17 film had a speed rating of 40 ASA (ISO), or 17 DIN (German Speed rating). In 1956, it was one of the fastest colour negative films available, a distinction it shared with Pakolor PK-24 film, also rated at 40 ASA. A typical clear sky, sunny daylight exposure, was 1/125 at f8. As the film had no orange colour correcting mask, it was easy to make good black and white prints from the negatives. Processing followed the same procedure as with the previous Agfacolor negative films, but the development time was slightly longer with the new film. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Despite new films being introduced during the 1960s (see below), the original unmasked Agfacolor CN 17 Universal film remained on the market until the end of the 1960s. By then the printing paper for unmasked negatives was no longed being manufactured (Agfacolor CN 111), but good prints could be made on Agfacolor paper MCN 111 and later versions of it, by incorporating an unexposed but processed piece of Kodak Ektacolor sheet film or Kodacolor rollfilm with the printing filters, or even with the negative itself, when making prints on Agfacolor MCN papers. This alleviated the very high yellow and magenta filtration values necessary when printing an unmasked negative onto a paper intended for use with masked colour negatives. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

An instruction leaflet for Agfacolor CN-17 Universal film. Printed in six languages (three shown above) this leaflet was enclosed in the film cartons of 35mm, roll film, and in boxes of sheet film. The instructions give the impression that the film was to be exposed only in daylight, electronic flash, or with blue flash bulbs, but it could also be exposed successfully in tungsten lighting, the colour correction being made in print making – hence the name “Universal”. The leaflet dates from May 1966. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) _print.jpg) |

.jpg) _print.jpg) |

.jpg) _print.jpg) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The roll film 2¼ inches square negative of the woodland scene (above left) shows a negative exposed in daylight conditions. The 2¼ inches square picture of the painting was taken under tungsten lighting and is appreciably more blue due to the colour of the tungsten light. The daylight exposed 35mm negatives (right above and immediately right) are slightly under exposed. The roll film negatives date from 1969, and the 35mm negatives date from 1968. Agfacolor CN 17 film had been withdrawn from the market by 1971 in favour of Agfacolor CN S film, 80 ASA/ISO, which featured colour correcting mask layers of yellow and orange-red. Note: The positives of the above

negatives, also the previous negatives from Agfacolor CNT (L

NT) film, were all produced using the freeware program Paint.Net. Further improvement could be made to all of the positives but the results shown are probably similar to ones likely to be produced by machine printing in the 1950s with no attempt to compensate for an excess of scene colour (e.g. green) giving a complimentary colour cast in the positive (e.g. magenta). |

.jpg) _print.jpg) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| On a personal note, the author first used CN 17 Universal film in 1968, and was processing the film and making prints from it in 1969. In 1970, he remembers taking pictures on several out-dated rolls of 120 CN 17 Universal film, as by then in-date film was unobtainable, CN 17 Universal having been replaced by Agfacolor CN S (see below). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

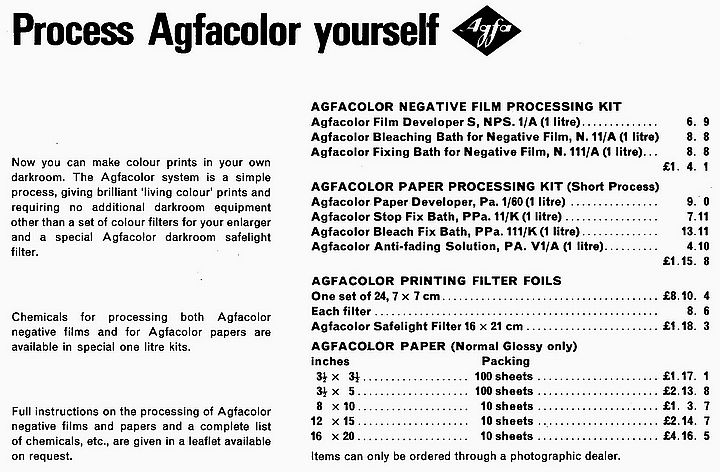

Amateur

Processing of Agfacolor Films, from 1958 In 1958, the processing and printing of Agfacolor materials had become straightforward and reliable enough for Agfa to release the processing chemicals and Agfacolor paper for sale to the general public without the need for attendance at an approved Agfacolor School. Packs of 1 litre chemicals for processing Agfacolor negative material and Agfacolor paper, plus various sizes and quantities of Agfacolor paper, became available for sale to the Amateur photographer. For processing negative films, the Colour developer, Bleaching bath, and Fixing bath were made up from powders to be mixed with water. A liquid colour developer, especially suitable for processing Agfacolor CN 17 films in the Agfa Rondinax developing tanks was marketed as an alternative to the usual 1 litre powder developer pack. The liquid developer could be diluted to suit the capacity of the Rondinax developing tank being used, and the developing time varied according to the dilution. CN 17 film was developed for 7 minutes at a 300ccs total dilution (stock solution of developer plus water), extending to 13 minutes at a total dilution of 700 ccs. A fourth solution, the Magnesium Sulphate bath, was necessary for the processing of Agfacolor negative film. This was “user make-up”, and consisted of 3% Magnesium Sulphate, or 30 grams per litre. It was also advised by Agfa to add 30ccs of freshly prepared developer to each litre of Magnesium Sulphate bath.

This negative process differs little from the 1950 negative processing sequence apart from the fact that the Magnesium Sulphate bath was now considered an essential part of the processing procedure. Notes.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

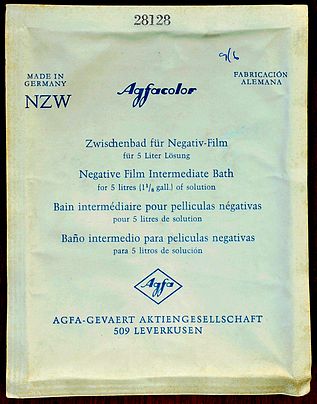

To the left, and below, is shown Agfa chemical packaging relevant to the Agfacolor Processing Sequence shown above. Agfacolor

Film Developer S, code NPS I (below, left) Agfacolor

Film Fixing bath, code N III (below, right) Agfacolor

Film Intermediate bath, code NZW (see left) The Fixing bath and the Intermediate bath were ready for use immediately. From 1971, the instructions for the mixing of Film Developer S stated the made up developer could be used immediately and no longer had to stand for 12 hours before use. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor

CN 17M ~ 1963

CN 17S film is listed in the British Journal of Photography Annual (BJPA) for 1968 under “Colour Materials for Still Photography”. In the column “Sizes Available”, the “BJ” gives a sheet film format for CN 17S. However, Michael thinks this maybe a mistake, as he can find no other reference to a CN 17S sheet film in any other of his historical Agfa or Agfa-Gevaert records. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor

CN S ~ 1968 CN S was obtainable in the usual roll film sizes, 35mm in 20 and 36 exposure cassettes, “Rapid” cassettes of 16 exposures, and “PAK” film cassettes of 12 and 20 exposures. “Pak” film was equivalent to 126 size cartridges, suitable for the Kodak range of “Instamatic” cameras, plus other cameras designed to take 126 size film. Agfacolor CN S film had a speed of 80 ASA (ISO), which at that time matched the speed of Kodacolor X film. As far as is known, Agfacolor CN S film was never made in any sheet film formats. Agfacolor CN S film gave a better colour reproduction than CN 17 Universal because it had an integral double colour mask (see below). |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

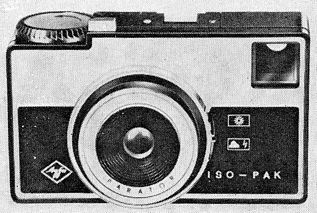

Two announcements of the new Agfacolor CN S colour negative film appeared in Photography magazine, the June 1968 edition. The first was in the News Desk section, which described the film, its cost, the sizes available and also the new Agfa Iso-Pak 126 cartridge format camera. It read: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A brand new colour negative film has just been announced by Agfa-Gevaert. Known as Agfacolor CN S, the film is the result of a carefully planned programme of research and has the following characteristics: high speed of 80 ASA; wide exposure latitude; very fine grain coupled with excellent definition; outstanding colour rendering and colour separation due to a double mask. The new film is available in the usual sizes and packs: roll, miniature and Rapid; and there is also a 126 Pak Film for cartridge-loading cameras. This means that practically every modern camera will accept CN S, and thus all amateurs will benefit from the latest results of Agfa-Gevaert's research. Agfacolor CN S is balanced for exposure in daylight or by light sources similar to daylight: flashcubes, blue flashbulbs and electronic flash units. Its speed of 80 ASA (20 DIN) provides a considerable exposure reserve, even with the simpler types of cameras. The grain is approximately as fine as that of a medium-speed black-and-white film, e.g. Isopan IF (40 ASA). CN S also has a yellow and a red mask to ensure optimum rendering and separation of colours coupled with good colour purity. These masks give the developed film its characteristic orange colour, and are improvements which are particularly apparent in high colour saturation of the yellow areas of the subject and in the purity of blue shades - no longer degraded in any way. Prices of the various sizes of Agfacolor CN S films are: 127 and 120 rollfilm 8s.11d (45p); Rapid cassettes 9s.6d (47.5p); 35mm 20 exposure cassettes 10s.7d (53p); 35mm 36 exposure cassettes 14s.9d (74p). 126 (Pak) cartridge 12 exposures 9s.6d (47.5p); 126 (Pak) cartridge 20 exposures 11s.8d (58p). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Coinciding with the introduction of the new Agfacolor Negative Film CN S film supplied in Pak cartridges (126), Agfa-Gevaert have also introduced their first camera for the 126 system: the Agfa Iso-Pak. The designers of this reasonably-priced camera have succeeded in making the process of changing the cartridge even more convenient and easy; the Pak cartridge is automatically raised on opening the back of the camera. The new Agfa Iso-Pak camera is of sturdy construction and smartly styled, with the following specification: format: 28 x 28mm; cartridge ejector; fixed focus f/11 lens; Parator shutter; symbol settings: Sun 1/80 sec; Cloudy and flash 1 /40 sec; big Newton optical viewfinder; accessory shoe flash contact; double and blank exposure prevention. A neat gift pack containing the new Iso-Pak camera, wrist-sling and one cartridge of 12-exposure Agfacolor CN S film is available at £4.13s.9d (£4.69p). A black plastic case for the camera and a special flashgun are also available for the Iso-Pak, selling at £1.12s.8d (£1.63p) and £2.4s.9d (£2.24p) respectively. |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) |

The page shown left is taken from an Agfa-Gevaert catalogue dating August 1968. It gives the prices of various current Agfacolor films. The unmasked Agfacolor CN 17 colour negative film (from 1956) still remained available. The new CN S film was introduced May 1968 (ref: B.J.P. Annual, 1969) with twice the speed of CN 17, at 80 ASA/ISO. The CN S film replaced the lower speed masked Agfacolor CN 17S film introduced in 1966. By 1966, Agfa-Gevaert were no longer manufacturing the slow speed Agfacolor CN 14 unmasked 35mm film. The catalogue page proclaims "New! 126 size Cartridge films". Agfa-Gevaert introduced 126 roll size films in 1968, five years later than the “Kodapak” 126 cartridge films for Kodak Instamatic camera range (from 1963). The Agfa film was available in two colour film types, viz: CT = transparency film and CN = colour negative film, and Isopan black and white film. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) |

Also taken from the August 1968 catalogue is the page shown alongside, of Agfacolor colour negative film processing chemicals, printing papers and printing filters (foils). The negative film processing chemicals then included the 'Intermediate Bath' (code NZW) packed in the same box as the 'Bleach Bath' i.e. NZW+NII. The chemicals for colour print processing included the 'Stabilizer' (code Pa VIS) packed in the same box as the 'Bleach Fix', PPa III/K + Pa VIS. Unlike Kodak, Agfa-Gevaert never sold their 1 Litre size chemicals for colour materials in kit form until much later on. Agfacolor paper MCNIII (for masked negatives) was being sold to amateur photographers in most sizes at the same price as Agfacolor CNIII paper (for unmasked negatives). The new (masked) Agfacolor CN S film was designed to be printed on the MCN paper. In early 1969, Agfacolor paper MCNIII Type 7 in sheets became available at the same prices as alongside. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) |

Further from the August 1968 Agfa-Gevaert catalogue. Alongside are shown the retail prices for the various films, both negative (CN 17 Universal and the new CN S) and transparency (CT18 and CK20), on sale at that time. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

NEW AGFACOLOR NEGATIVE FILM The way in which the CN S film forms the masks is interesting. There is an additional green sensitive layer between the magenta and cyan forming emulsions. During colour development a colourless compound is formed with the product of oxidation of the developer in the masking layer; then the remaining uncoupled part of the coupler in this masking layer is oxidised in the bleach to form a yellow dye which is in fact a positive yellow mask to correct the unwanted blue absorption of the magenta negative image. Presumably the green sensitivity of both the magenta dye forming layer and the yellow forming masking layer are carefully matched so that the amount of yellow dye present in the finished negative is inversely proportional to the negative magenta image. The red mask is produced in the cyan layer which has a special mask former built into it in addition to the normal cyan forming couplers. This special masking substance reacts with the uncoupled cyan couplers i.e. those not used during development, to generate the cyan negative image and form a red dye positive mask in the bleach. It is an ingenious system, and it is interesting to note that both masks are coupled at the bleaching stage. The system is quite different from the Kodak one, in which the cyan and magenta colour couplers are themselves coloured, so those which are not coupled remain to form the positive masks. Agfacolor MCN III paper is recommended for printing from the masked negatives since it is adjusted speedwise in the individual layers to suit the new film. The same paper can be used to print CN 17 negatives by using a mask substitute filter. Later in the year an even faster paper, to be known as MCN III Type 7 will be marketed, and this will have the advantage of reducing printing time, thus enabling more prints to be produced over a given period, assuming negatives of similar density are being printed on both types of paper. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High Temperature Processing of 80S Professional

Film (and CNS 2) in Rotary “one shot” Processors Processing was also possible at 75°F (24°C). A “high temperature” Rotary Processor procedure was possible for processing film in “Colenta” or “Metorette 70” type machines, working at 75°F. It was mainly for use with Agfacolor 80S Professional sheet and roll films, but it was also possible to process Agfacolor CNS 2 film using the same solutions and bath temperatures. This sequence dates from 1975. |

||||||||||||||||||||||||||||||||||||||||||||||

|

Load film in total darkness, or under Agfa Gevaert safelight filter, No. G4.

Total time: 28 minutes. Notes:

|

This film was processed in Agfacolor N series chemicals, similar to the older Agfacolor CNS film. It was replaced by Agfacolor 100 film in 1982. |

|||||||||||||||||||||||||||||||||||||||||||||

| Agfacolor CNS 400 in 1979 | ||

|

Agfa Gevaert introduced Agfacolor CNS400 film in 1978, a 400 ASA(ISO) high speed colour negative film for processing in the Kodak C-41 colour negative film process or Agfacolor Process AP70. Later, in 1981, two new professional colour negative films appeared, N100S for daylight exposure, and N80L for tungsten lighting in 120 rolls and sheet film, both designed to be processed in Kodak C-41 or Agfa AP70 and the N100S film replaced Agfacolor Professional 80S film. With a speed of 400ASA (ISO) Agfacolor CNS 400 colour negative film was claimed to be ideal for elusive shots in subdued light, or high speed action shots. Also claimed to have a very high resolution with amazingly fine grain. It was available in 35mm, both 24 and 36 exposure cassettes, as well as 20 exposure cartridges of the 110 film size (The 110 cartridge-based film format was introduced by Kodak in 1972. It was essentially a miniaturised version of Kodak's earlier 126 film format. Each frame was 13mm × 17mm, with one registration hole. |

|

|

Agfacolor 100 in 1982 Both films were processed in Agfa AP70 chemicals, equivalent to Kodak process C-41. Agfacolor 100 film eventually replaced Agfacolor CNS2 film, one of the last Agfa Gevaert films designed to be processed in “Process N” chemistry. |

||

|

||

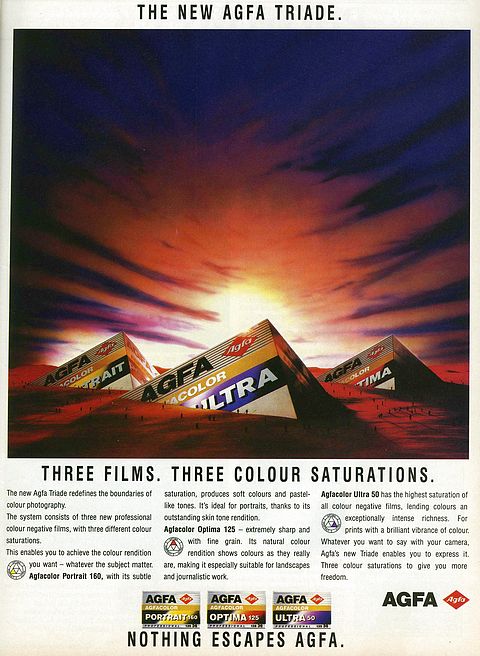

| Amateur Photographer test of Agfacolor

Ultra, Optima and Portrait (October 13th 1990) Joël Lacey looks at Ultra, Portrait and Optima: the trio of films forming Agfa's latest assault on the colour print film market. |

|

|

Naming a new concept in film making after a type of Chinese secret society - Triad - might not be the most subtle marketing exercise ever, but the idea of having essentially the same film with three very different levels of colour saturation is nonetheless a very interesting development. The three films - Portrait, Optima and Ultra - have different characteristics but are based on the same film technology. The mingling of different speed emulsion layers in different ratios is what makes the films differ in both film speed and colour saturation. This saturation is, according to Agfa, twice as great in Optima as it is in Portrait, and twice as high again in Ultra as it is in Optima. What this means in real terms is probably best ascertained from examining the photographs, but there are a couple of points worth looking at first. There are other differences between the three films, including one which would seem to go against a conventional wisdom which states that the faster the film speed, the finer the grain. But with Triad the price to be paid for the increase in colour saturation in Ultra is an increase in the graininess, as can be seen from the eyeball pull-ups from the portrait shots. In all things, Optima steers the middle course between the other two films, and it is also the most widely available of the trio. Neither Ultra nor Portrait is available in a larger format than 120, while for Optima sheet film up to 10x8in is available. All three films carry the 'Professional' tag and as such, expectations are bound to be quite high in terms of the quality of resolution and colour saturation involved. As far as the typical user is concerned - ie producing prints of no greater than enprint size - there is no doubt that each of the films fulfills its potential as far as resolution and contrast is concerned. A greater test occurs for these films as the shots are enlarged. In the vast majority of cases, the way in which a print looks is as much to do with the way it has been developed as it is with how critical the exposure was at the time of shooting. Unless adequate care is taken when the film is processed and printed - be it Agfa's Triad, Kodak's Ektar or Fuji's Reala - the quality will not be evident. Important Factor Food photography, on the other hand, may involve using highly saturated colours to make the food look both fresh and appetising, whereas for general photography where a sense of realism is welcome, a film which takes equal notice of flattery and saturation may be the best bet. With these criteria as the basis for film selection, Agfa is attempting to allow the photographer to give different treatment to different subjects while still keeping the same type of film in terms of some of its characteristics. |

|

Glancing at the diagram (alongside), it is interesting to note the bias in the films towards individual colours (assuming that the central origin of the axis is a point of no colour saturation). Historically, Agfa has always tended to tone down its reds a notch or two compared to the opposition, and this still seems to be the case with the Triad films. The difference in blue and magenta sensitivity and saturation between Ultra and the other two emulsions is significantly greater than for other colours. The addition of extra-sensitive material to a film is obviously going to have some influ-ence on the thickness of that film and, without the film base, Ultra is 50 per cent thicker than Portrait. Film Latitude |

|

Ultra's raison d'etre is to give saturated colours. It succeeds (left hand side). Optima's fleshtones are the most realistic of the quartet (right hand side). |

Portrait film de-emphasises skin problems for flattering portraits. Agfacolor Optima 125 gives good crisp whites Agfacolor Portrait 160 is the fastest film but with the finest grain ! |

|

|

||

|

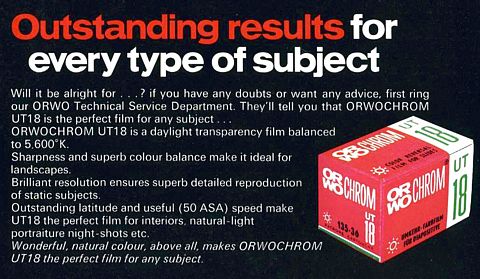

In 1969, Agfa-Gevaert introduced “Duplichrome D 13”, a sheet film designed for making large duplicate colour transparencies. It was intended for making duplicates from original Agfa-Gevaert reversal films, such as Agfachrome 50S and 50L Professional films. Successful duplicates could also be made from Kodak Ektachrome and Kodachrome original transparencies. Duplichrome D 13 was available in sheet film sizes from 4 x 5 inches to 20 x 24 inches. The film had a speed of approximately 10 ASA (ISO) and was designed for exposures in enlargers with colour heads with a recommended exposure time of 1 second to 10 seconds. Original transparencies could be printed directly onto the duplicating film without the need for contrast masking or the use of the “flashing” technique. |

||

|

|

|

|

|

|

|

Alongside is shown an instruction manual for using Duplichrome D13 film dating from May 1974. Printed in German, it gives descriptions of the Agfa subtractive yellow, magenta and cyan filters used to correct the colour balance of the duplicating film, plus the filter factors and a good colour correction table listing the filters to correct any colour cast. It is interesting to note that the table also lists corrections for colour cast when Tri Colour filters are used. For instance, a yellow (Gelb) cast required an increase (Verlangern) in exposure through the blue (Blau) filter. The Agfa filters used in Tri Colour printing were L622 Red, U531 Green and U449 Blue. Mixing instructions are given for the five solutions for the reversal process with two processing sequences, Normal and Schnell (fast). This small booklet packs a lot of information into its twelve pages. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Processing

Procedure for Duplichrome D 13 Either of two processing sequences could be used, a normal sequence taking 64 minutes wet time, and a rapid sequence taking 45 minutes wet time. The rapid sequence was mainly for use in processing machines such as “Colenta” and the processed transparencies had limited keeping properties due to the shorter processing times. It was suggested by Agfa to start the processing sequence in rotary machines with a “Pre Wet” bath before the First Development step.

Notes:

Duplichrome D 13 film remained on the market for many years. A new duplicating sheet film was introduced by Agfa-Gevaert in 1993 as “Agfachrome Duplicating Film”. It was available as 4 x 5 inches, 10 x 8 inches, and in 35mm. An Agfa-Gevaert catalogue for March 1993 states that “Other sizes of duplicating film available shortly”. It was designed for processing in Agfa AP–44, which was the equivalent of the Kodak E6 process. Agfachrome Duplicating Film was most likely the replacement product for Duplichrome D 13. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Agfacolor

Reversal Duplicating Film (Reversal Coyping Film) Agfa-Gevaert also manufactured Agfacolor Reversal Duplicating Film. As far as is known, this film was for making 35mm duplicate transparencies from 35 mm originals and was only available in 35mm format. The film was originally known as Agfacolor Reversal Copying Film and was used by authorized Agfa processing laboratories for the production of 35 mm duplicate transparencies from the early 1950s. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Agfacolor paper was first demonstrated at a meeting of the German Cinetechnical Society (Deutsche Kinotechnische Gesellschaft) in 1942 at Dresden, but due to wartime conditions, and lack of basic materials, Agfa did not release the Agfacolor negative / positive process until January 1949, and then only to a few laboratories in East/West Germany and later to Switzerland and Russia. Agfacolor film was made at Wolfen, in East Germany, and the colour printing paper was made at Leverkusen, in West Germany (note: although this is believed to be essentially true, some paper was manufactured at Wolfen; see below). After the war, the 'Rights' to the Agfa brandname were lost to the West German company, and the Wolfen company's products were rebranded ORWO (ORiginal WOlfen). The negative film, like the early cine film, was available in daylight, Type T, and artificial light, Type K. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Wolfen and ORWO, Film and Colour Paper: Agfa were making colour motion picture film, negative and positive, possibly since 1939 at their plant at Wolfen. Much later, when the film was marketed, it was labeled “Veb Filmfabrik Agfa Wolfen. Deutsche Demokratische Republik”. In the late 1940s, Agfacolor films Type T and Type K were also being manufactured at their West German factory at Leverkusen. By 1956, the Leverkusen factory was making the, then new, Agfacolor CN17 Universal colour negative film, (40 ASA(ISO)) designed for use in Daylight and Artificial light. At that time, CN17 film was only made at Leverkusen, the East German Agfa factory continued to make Type T and Type K films independently. As from 1956, the East German films were re-named, “Agfacolor Ultra “ negative films, with an increase in speed from 12 ASA(ISO) to 32 ASA for both types. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Alongside is shown a box of Agfacolor Ultra K Negative sheet film, manufactured in 1963 in East Germany by Agfa at Wolfen. This film is balanced for Tungsten light exposure at a speed of 40 ASA (ISO). It has an expiry date of April 1964. From 1964 onwards, products

made at the East German Wolfen factory were labeled ORWO (meaning

= 'Original Wolfen'), and this film became known as “Orwocolor

Negative, NK 17” The equivalent Daylight type film

was known as: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

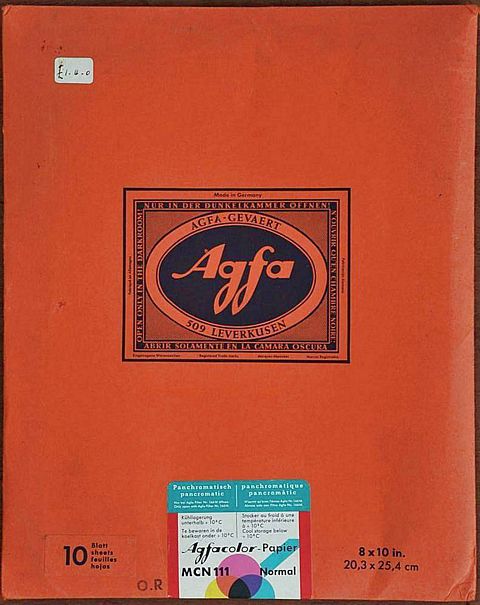

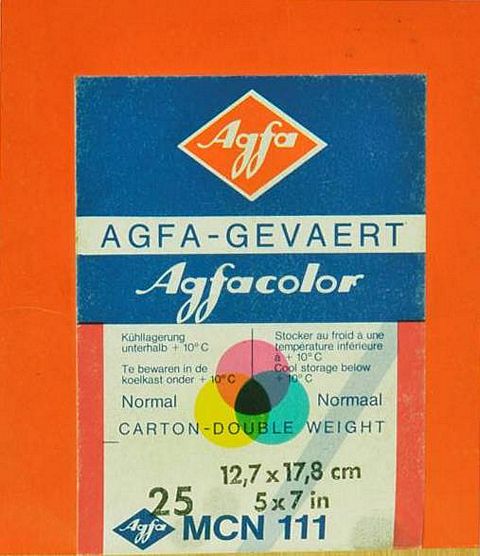

| Until recently (March 2019) Michael Talbert believed Agfacolor paper was only made at Leverkusen, West Germany, possibly from the end of World War 2, and then marketed in Europe from 1949. However, below is shown a picture, plus side views, of a box of Agfacolor paper 9 x 12 cms, clearly marked as being made by Agfa at Wolfen, expiry date July 1960. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A box of 25 sheets of Agfacolor paper, size 9 x 12 cms, made at the East German factory at Wolfen. The paper contrast grade is “Hart”, (Hard), suitable for soft contrast or under exposed colour negatives. This paper would have been balanced for printing from unmasked colour negative films, such as the Agfacolor East German colour negative films, Ultra T for daylight, and Ultra K for artificial light. The emulsion number is 022 436, and the filtration given for changing over batches of paper is 10 00 10 (10 Yellow, 0 Magenta, 10 Cyan), given in “Wolfener Filter”, possibly equivalent to the Agfa colour printing filters. It is not known what the number 0784 refers to, and, strangely, there is no “paper code” printed on the label. The equivalent code printed on a similar packet made at Leverkusen, West Germany, would have been CH 111.

Left hand side of box:

Right hand side of box:

This is now a rare box, from a seller on the German e-bay web site. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Agfacolor

April 1951 Price list When Agfa negative / positive

colour materials arrived in the UK, in July 1951 (see below),

it was the policy of Agfa to only sell Agfacolor chemicals and

colour printing paper to those who had completed a course on

Agfacolor photography at one of the Agfacolor Schools. In 1951

there was an “Agfa Photo Schule” at Leverkusen. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The first item in the left hand column (see page above) is a kit of print processing chemicals for Agfacolor paper making 1 litre of each of the solutions apart from the Anti-Fading solution. This would have to be purchased separately in either ¼ or 1 litre bottles to be diluted to 10 times the volume. The Agfacolor 1 litre paper processing kits are not mentioned in any of the 1950s “Agfacolor” books by H.Berger. “Agepon” is a Wetting Agent. “Agfacolor Umrechnungstabelle” is some kind of measure for working out the exposure times for Agfacolor paper. “Agfacolor Rechenschieber” translates as a “Slide Rule”, again for calculating exposure times when changing the filtration using Agfacolor glass filters, using the filter factors given by Agfa. “Agfacolor Farbstern” or “Colour Star”. There is a diagram of a “Colour Star” in the 1950 edition of the Agfacolor book by H.Berger. It is a circle showing coloured triangles spaced around a circle. Green is opposite Magenta, Blue is opposite Yellow and so on. It might be a some kind of chart or poster to hang up in the darkroom. “Agfa Filmlack”. Filmlack is a lacquer for coating onto Agfacolor negative films to protect them from scratches, marks etc. It was applied onto the emulsion side after drying. "Agfacolor Lichschutzlosung” is an Anti Fading solution for Agfacolor paper. This solution must have been introduced from mid 1950 to early 1951 and was the last bath in the processing sequence before drying. Prints were bathed in the Anti Fading solution and dried without further washing. The very early processing sequences recommended Agepon Wetting Agent as the last bath before drying. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1951