| Kodak Ektachrome Colour Transparency films - researched by Michael Talbert |

|

Kodacolor Aero Reversible Film In 1939, Vittum and Jelly, of Eastman Kodak, discovered a type of colour coupler which, unlike the Kodachrome developer couplers, could be combined with the three emulsion layers of a colour film. The new couplers were incorporated into a resinous binder. They were known as “Protected Couplers”, as they were carried in small particles of organic materials which protected them from any reactions of the silver bromide emulsions. The colour couplers were then within the emulsion but not in complete physical contact with it. Like Agfa’s Agfacolor Neu film of 1936, any colour material, film or paper, having the colour couplers combined with the three emulsion layers at the time of manufacture, could be processed in a much simpler, and much faster, manner than that of Kodachrome. Only one colour developer and one bleach bath were required. The first film manufactured

by Eastman Kodak containing “Protected Couplers” was

Kodacolor Aero Reversible Film in 1940. The processing sequence and chemical baths for Kodacolor Aero Reversible film were not unlike the processing procedure and baths for the earliest type of Kodak Ektachrome sheet films. Kits of chemicals for making up the five processing baths were available. The procedure was much like Process E1 but with longer times, very likely at 68°F (20°C). The time taken to process the film, not including drying, was around 90 minutes. It was probably about 6 to 10 ASA and had a high contrast. Two sets of filters were supplied with the film, one filter to correct for the various emulsion differences, and to balance it for average daylight. The other filter, or filters, were to correct for “haze”, or blueishness in distant subjects. The “Haze” filters were likely to have been, “Wratten Filter No.1”, and “Wratten Filter No.2A”, 2A being slightly stronger. It was replaced, or renamed, ”Ektachrome Aero film – High contrast”, possibly in 1946. |

|

The chronology of the Kodak Ektachrome processing chemistry, E1 through to E6, can be learned by reading the Sections below. Because the colour couplers were included in the emulsions (unlike Kodachrome), Ektachrome film could be processed using a much simpler procedure than Kodachrome, involving only one colour developer. Essentially, the E1 Process,

though not known by that title at the outset, was available from

1946 in the US and 1947 in the UK. The E2 Process appeared around 1955 for Kodak's 32ASA (ISO) film. Process E3 arrived in 1959 with a 50ASA film. Then a jump was made to a 160ASA Ektachrome (also known as High Speed Ektachrome) later that year. 1966 saw the introduction of Process E4 for Ektachrome X and High Speed Ektachrome. Processes E3 and E4 were used during the same years and some films were occasionally mixed up by users, so Kodak tried for a single new improved process with accompanying new films. Process E5 proved to be a development hiccup. Process E6 appeared from 1976

and three new E6 Ektachrome films accompanied this introduction,

namely Ektachrome 64, Ektachrome 200 (ISO; Daylight balanced)

and Ektachrome 160 (ISO; Tungsten balanced). |

|

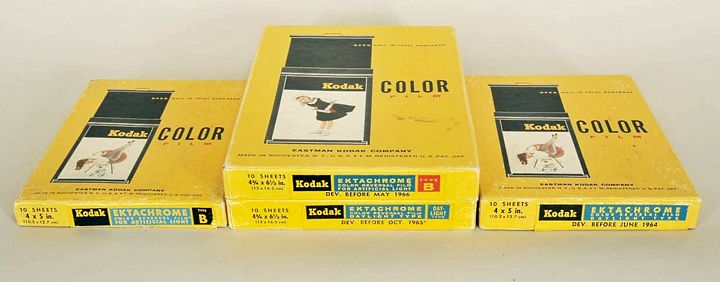

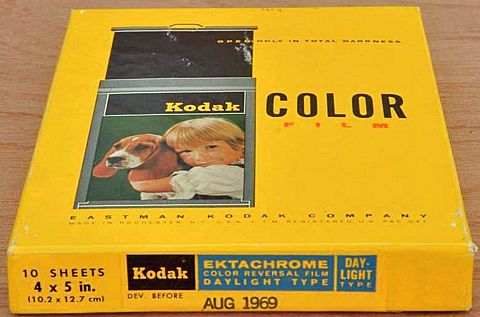

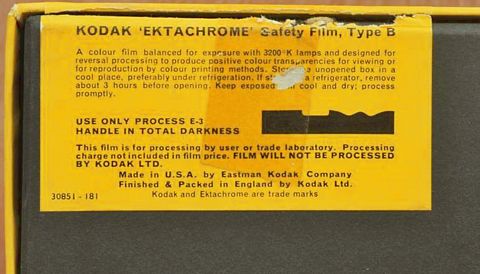

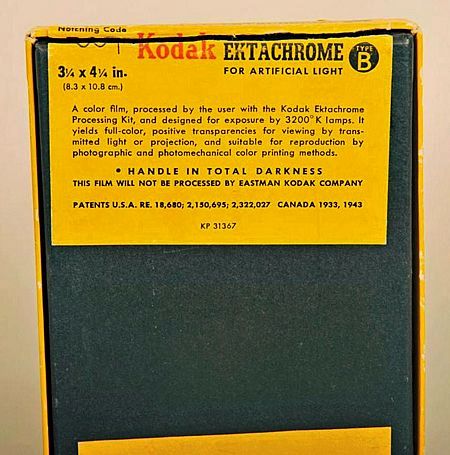

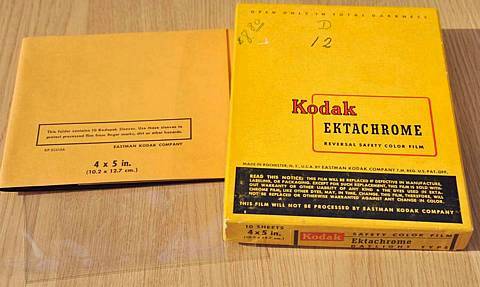

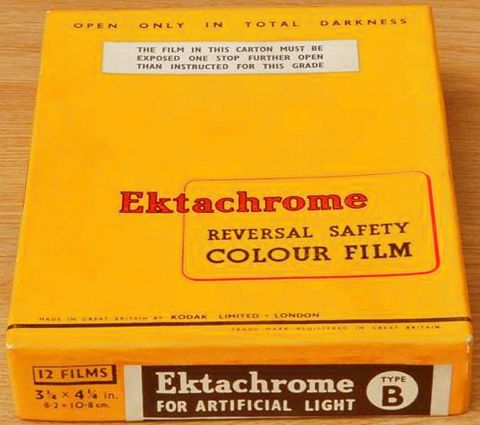

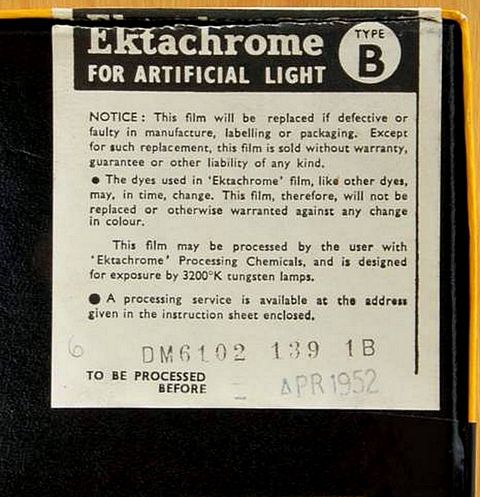

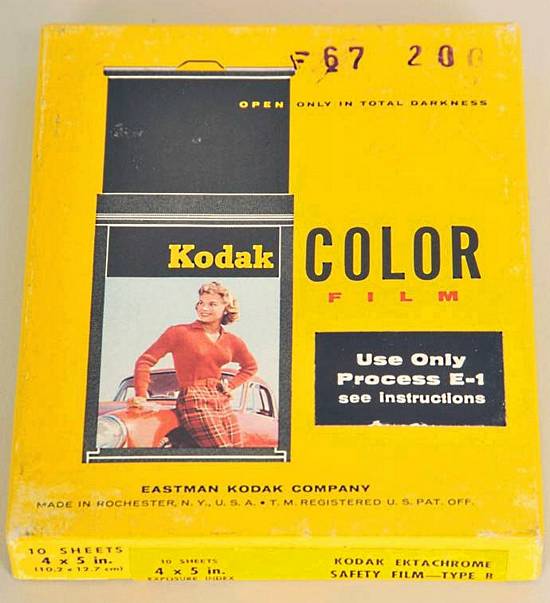

Ektachrome film was first introduced in sheet film format in 1946. Based on the earlier Kodacolor aero film, Ektachrome had a much lower contrast and was obtainable in a Daylight balanced film and an Artificial light balanced film. The artificial light type film was known as 'Type B', balanced for 3200°K lamps (see picture, below). The Daylight film had a speed of 8ASA (ISO), and the Type B film was rated at 10ASA (ISO). Both versions were designed for processing by the photographer in the “Ektachrome Processing Kit”. There are reports of Ektachrome film being processed in “Kodacolor Aero Reversible film” chemical kits, but the first developer had to be substituted for another type. One report states that the Kodacolor Aero kit gave “bright, contrasty transparencies with slight blueness in the shadows” on Ektachrome film. About a year later, a daylight type roll film was put on the market. The emulsion was exactly the same as the daylight sheet film. It was supplied in 620 and 120 sizes and the data sheet warns “It cannot be used satisfactorily in box or other simple cameras”. It’s speed to daylight exposures was 8 ASA, but Michael Talbert has seen where some sources mention a speed of 6ASA. It has also been reported that Kodak reduced the speed by one third of a stop for the daylight film in 1948 due to a re-assessment of the film’s capabilities. The actual film was not changed and no evidence can be found of this appearing in the official Eastman Kodak data sheets for the daylight type film. Both films were “code notched” for identification in the dark. It was not possible to use a safelight; both films had to be handled in total darkness. The daylight film had one notch cut into the edge of the film and the Type B film had two notches. It was possible to expose the Type B film to daylight using a Kodak Wratten filter No. 85B on the lens. The speed of the film then dropped to 6ASA. Flash exposures, with clear flashbulbs, were made with a Kodak Wratten filter No. CC95 and the instruction sheet gives tables listing various guide numbers for average and large reflectors when using clear flashbulbs. From 1946, both types of sheet film were packed in boxes of 12 sheets. This quantity may have been changed to 10 sheets per box as from the early 1950s. Included in the earlier boxes of 12 sheets were 12 “Kodapak” transparency sleeves. When each sheet of Ektachrome film had been processed and dried, the finished transparency was inserted into a “Kodapak” sleeve for ease of handling to prevent fingerprints while also protecting the transparency from scratches. Below is shown an Ektachrome 4 x 5 inch sheet film box, dating from 1948. This film was balanced for Daylight. The “Develop Before” date is July 1949, meaning that the film was likely manufactured around September 1948. Some information has been taken from a 1948 Data sheet for the film. The Daylight Type film had a speed of 8 ASA (ISO). Best colour rendering was obtained by exposing in bright or hazy sunlight. Blue casts would result in exposing on an overcast day, or under a clear blue sky, or photographing distant views. To correct the blue cast Kodak recommended placing yellow filters over the lens such as CC13, CC14, CC15. The CC13 was the weakest but CC15 would correct a fairly strong blue cast. The film could be exposed to

other light sources such as: |

|

Prices

of Ektachrome Sheet Film in the UK in 1950~1952 The 3¼ x 2¼ inch is for sale at £1.16s.5d (£1.82p) per box. The quarter plate 4¼ x 3¼ inch is for sale at £2.10s.11d (£2.54p) per box. These prices did not include the cost of processing the film. It is very likely that this is “in date” film. However, the George Childe

prices for the Ektachrome sheet film boxes may have been either

trade prices or the price without Purchase Tax. This possibility

exists because, in the “Kodak Price Supplement” to

a Kodak catalogue for May 1952, a box of 2½ x 3½ inch

size Ektachrome film cost £1 15s 0d (£1.75)

for 10 sheets. The quarter plate size film, of the same

quantity was £2 10s 0d (£2.50). The “Kodak Price Supplement” for May 1952 lists both the Daylight and the Type B film for sale in sizes from 2¼ x 3¼ inches to 8 x 10 inches in boxes of 10 sheets. The film listed for sale may have been manufactured by Kodak at their factory at Wealdstone, Harrow, although the advertisements for Ektachrome film in the British Journal Photographic Almanacs for the early 1950s give the impression that only the Type B film was being made at Harrow, and the Daylight type film was not available. The title printed in the price list: “Ektachrome Type B sheet film and Ektachrome Daylight Type sheet film (Not available for export)” further suggests that the film was being manufactured in the UK. Processing Service Kodak would accept film sizes from 2¼ x 3¼ inches to half plate 6½ x 8½ inches for processing. For some reason, 8 x 10 inch film was not processed by Kodak, but at that time other trade laboratories were beginning to set up 3 gallon tank lines of the five solutions required to process Ektachrome film. John Piercy, Ltd, 34A Bryanston Street, London (near Marble Arch), was one of the first colour processing laboratories in the country to offer a processing service for Ektachrome, although I believe they first were established in Leicester Square, London as long ago as 1948. The Kodak processing service operated on a basis whereby the more sheets of film sent in for processing at one time, the lower was the price charged to process each individual sheet. Examples of processing charges, May 1952.

The prices are per sheet of film processed and were free of Purchase Tax. In 1950, a box of black and

white sheet film, such as Kodak Super XX, size 4¼ x 3¼ inches,

would have cost about 14 shillings (70p) for a 24 sheet

box. In the same advertisement are “Ektachrome Processing Outfits” for sale at £1 10s 0d each (£1.50 ) but it does not say what size of outfit or how many films can be processed in each outfit. Kodachrome Professional sheet film was withdrawn from sale in May 1951 and was no longer manufactured. The processing service for this film was discontinued on 31st July 1952. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektachrome

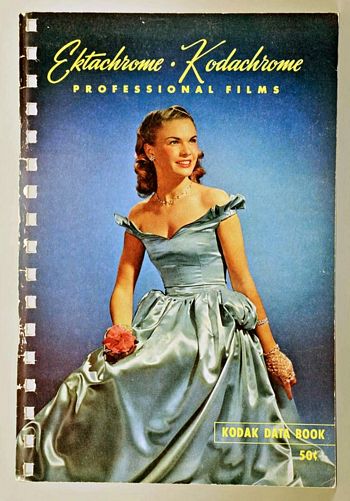

Exposure The instruction sheet and data sheet for the 'Type B' film included an exposure table for exposures to 3200°K lamps with subject to lamp distances ranging from 5feet to 20feet (6.1m). It is interesting to note that neither the instruction sheet nor the data sheet for the earliest made Ektachrome Type B film included any reference to increasing the exposure over a certain exposure time length due to Reciprocity Failure effects. The book “Ektachrome/Kodachrome Professional Films” states in the chapter “Exposure of Color films”, that the photographer must make his own tests using his own lighting set-up for exposure onto Type B film. For critical work film the same emulsion number was used to make the trial exposures and the final exposures. Eastman Kodak stated that the manufacturing variations between successive batches of film were small, with colour differences easily corrected within the range of Kodak CC23, CC33, and CC43 filters. The CC range of Kodak Colour Compensating filters marked in subtractive colours did not exist in the mid-1940s. The equivalent to CC23, CC33, and CC43 was likely to be the 10 densities of Yellow, Magenta and Cyan. (CC10Y, CC10M,CC10C) The speed of the film was unlikely to vary much more than half a stop at the time of manufacture. As far as Michael is aware, the standard exposure for the earliest Ektachrome film was about 1 second, and production tests by Eastman Kodak may have been made at this exposure. It is likely that exposures longer than 5 seconds may have had to be increased somewhat because of Reciprocity Failure effects. This increase would have varied slightly from one batch of film to another. By the late-1940s, a supplementary instruction sheet was being packed into Ektachrome Type B film boxes giving exposure and filter recommendations for times of 10 seconds and 120 seconds. An idea of the exposure increases are given by a later table dating from the early-1950s. An exposure of 10 seconds required an exposure increase of about 1 stop, (i.e. equivalent tp an exposure increase to 20 seconds), and 120 seconds required an increase of around four times the 120 second exposure (i.e. equivalent to an exposure increase to 8 minutes !). At longer exposure times the colour balance would change necessitating the use of Colour Compensating filters to correct the balance. Ektachrome

Processing From 1946, all Ektachrome film was made by the Eastman Kodak Company at Rochester, N.Y., U.S.A. As far as Michael Talbert understands, the film was first marketed in the U.K. in 1947. As the film was intended to be processed by the user, kits of chemicals were available in 2 litre and 5 litre sizes. In the U.K., in 1947 to 1948, only small amounts of Ektachrome sheet film and the necessary processing kits were imported into the U.K., mainly for bonefide professional photographers. Owing to import restrictions at that time, and to make the most of the processing chemicals that could be imported, Kodak in the U.K. set up a processing service for Ektachrome film at Harrow. By 1948, only the Type B film was available (see Early Ektachrome Film, above). Michael believes (ref: the British Journal Photographic Almanacs) that Kodachrome sheet film was not actually sold in the UK after the war. Although the BJ Almanac for 1947 mentions “Kodachrome Professional Film” in the Kodak advertisement (referring to sheet film Kodachrome), this "Kodachrome Professional Film" had been replaced by “Ektachrome Film” in the Kodak advert in the 1948 BJ Almanac. By 1950 Ektachrome film had replaced Kodachome in sheet film format and by 1951 Kodachrome sheet film production had ceased altogether. Eastman Kodak presumably wanted to sell an alternative to Kodachrome sheet film and hence made Ektachrome available. The main reason for Kodak deferring from Kodachrome is likely to be that Kodachrome in sheet film format would have been difficult and expensive for them to process. 35mm film is quite the opposite, since multiple films can be spliced together in the same way as Motion Picture film, and passed through machines as one continuous band of film. But you can’t splice together sheet film, and also it comes in different sizes. No wonder they stopped making it altogether in 1951!. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

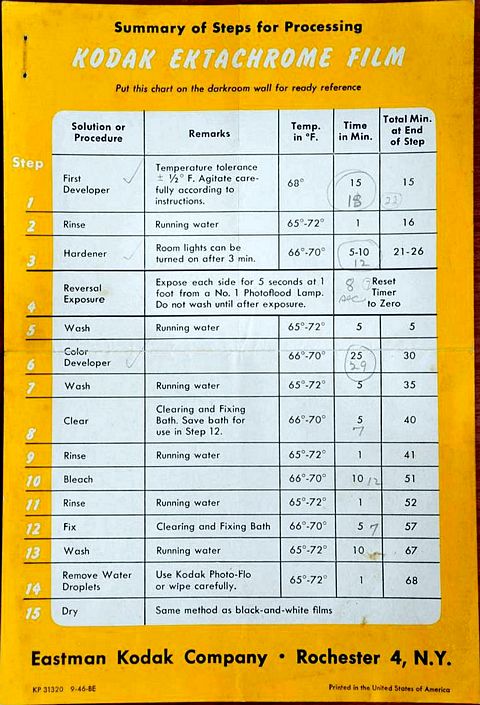

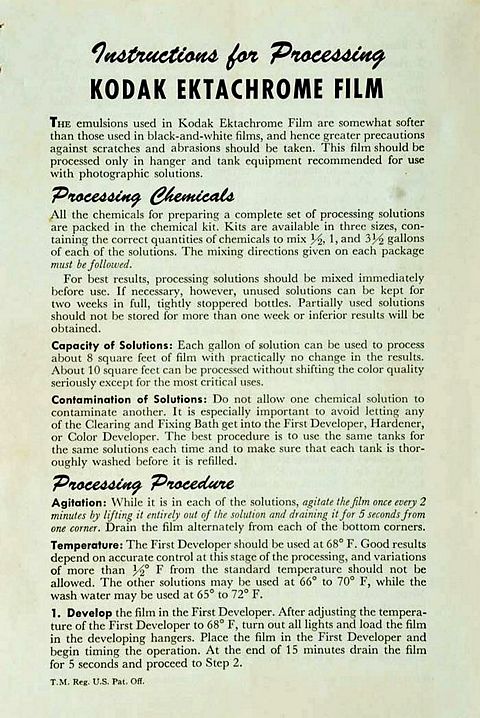

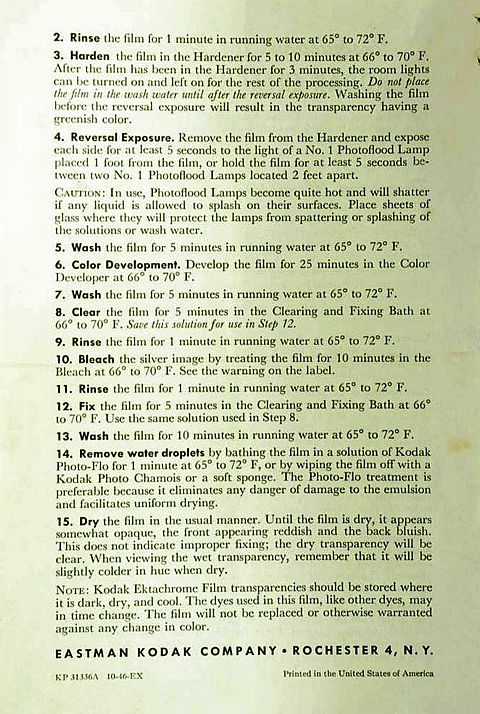

1946

Processing sequence Lower down are two pages of processing instructions, which date to October 1946. These instruction sheets have the number KP31336 with an A suffix, suggesting they are a first reprint. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Notes:-

By 1949 Ektachrome film was being made at Kodak’s Harrow plant in the U.K. Various formulae for the five processing solutions were suggested in the late 1940s to early 1950s, many of them published in the British Journal of Photography magazine and “BJ” Almanacs. Most formulae for the Colour Developer used May and Baker’s “Genochrome” for the colour developing agent. The quantity of this could be varied to alter the colour balance when making up the colour developer. In 1949, the process times were reduced by enabling the higher temperature of 75°F. The film was now hardened during manufacture, to withstand the higher processing temperature. As far as Michael knows, by 1952 the film was only manufactured by Eastman Kodak at Rochester, N.Y., and Ektachrome film was no longer made in the U.K. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Below is a later sequence, dating from 1954, with the higher 75°F temperature timing. At this time, Ektachrome film was obtainable in Daylight and Type B sheet film, and Daylight type 120 and 620 roll film. Various sizes of processing kits were available. Post 1955, with the arrival of Process E2 films and chemistry (see next Section), this earlier chemistry became known as Process E1.

Notes:-

E1 sheet films and E1 processing

chemicals only were listed for sale in the February 1960 Kodak

Professional Catalogue for the UK. |

|||||||||||||||||||||||||||||||||||||||||||||||||

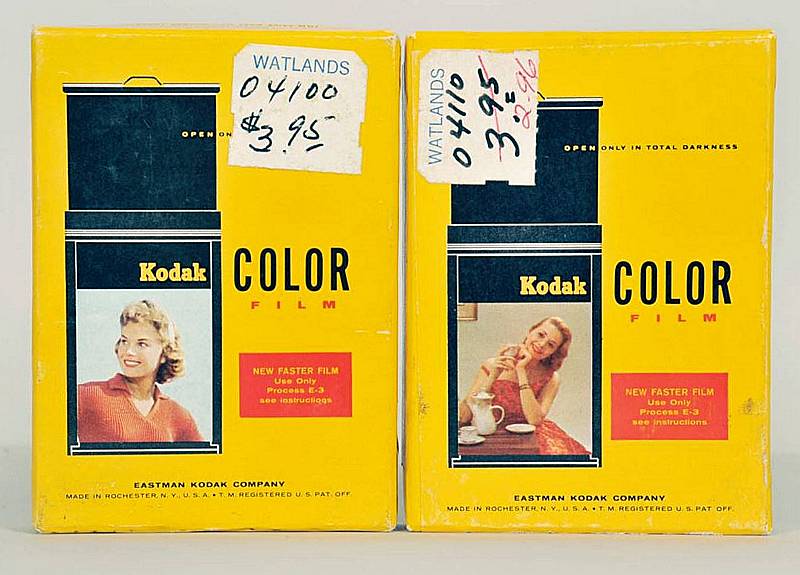

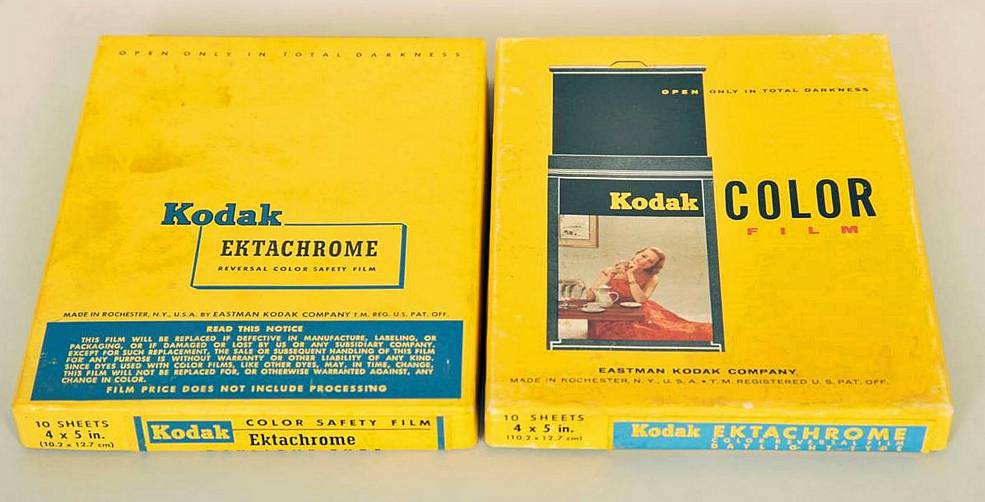

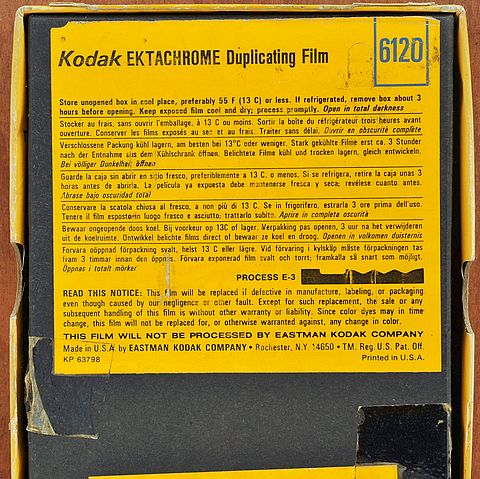

| Boxes of Ektachrome 'Process E-1' film, mid 1950s to 1960. | |||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Below are two further boxes

of Ektachrome film for Process E1.  |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

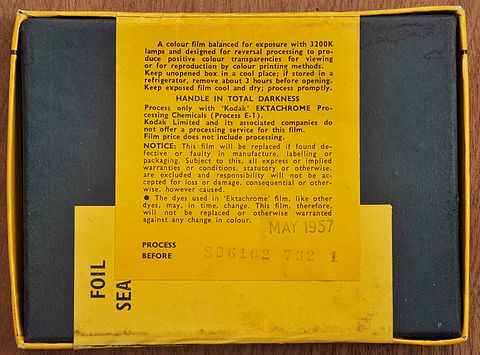

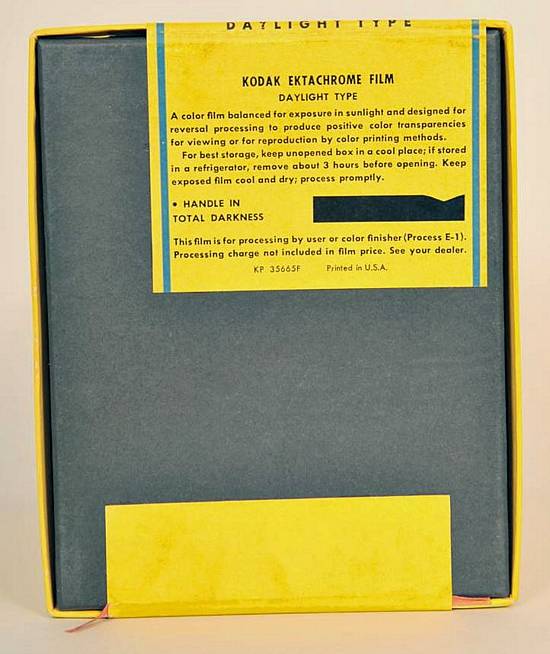

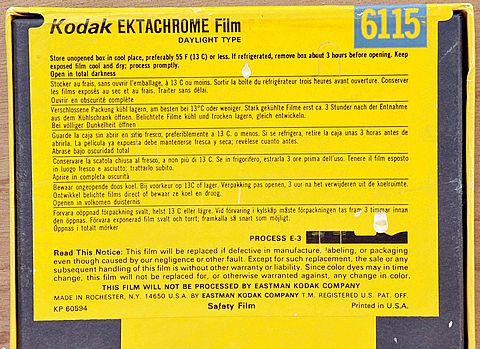

Rear label from Ektachrome E1 film box (left hand side, above) dated April 1959.  |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

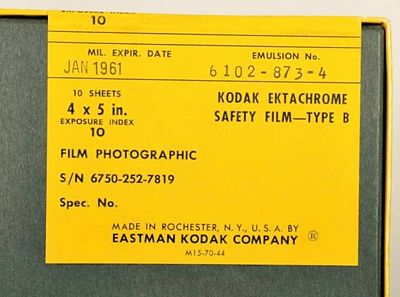

Box

of Ektachrome Process E-1 film ~ 6102

It was also suggested that, for critical use, the photographer made a trial exposure at an exposure time of one second to find out if any colour correction filter was necessary at this exposure time. If a filter was found necessary it would be combined with any other colour correction filter(s) when the film was exposed at longer exposure times. The supplementary data sheet for this particular batch of film, batch No. 6102 873 gives the emulsion speed as “Normal”, i.e. 10 ASA (ISO). The data sheet also gave information on colour balance correction for exposures at long and very long exposure times. For long exposure times of about 10seconds a CC05C filter, (5 unit Cyan filter) was suggested plus an exposure increase of half a stop. For very long exposure times of around 120seconds a CC10C filter, (10 unit Cyan filter) was suggested plus an exposure increase of 2 stops. From this information it can be concluded that the colour balance of the film turns red with longer exposures. Example

of how to use this film: The supplementary data sheet also suggested any exposure adjustment when using clear flash bulbs as the light source at 1/50th second. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

The sealing label on the back of the above box can be seen to the left. It is a bit odd, totally unlike the sealing label of the later E3 boxes, and may possibly have been made for a special purpose, or perhaps Eastman Kodak ran out of the normal labels and had to print some improvised labels for the very last batches of E1 film ! Above the expiry date of "Jan

1961" can be read "MIL. EXPIRY DATE". |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In 1955, higher speed 32ASA (ISO) Ektachrome Daylight roll and 35mm films were put on the market, specifically designed for the amateur photographer. For the 35mm photographer it was a faster alternative to the well known Kodachrome Daylight film. Average exposure was 1/50th second at f11 in bright sunlight. The film was also suitable for exposure with blue flash bulbs and electronic flash. This type of lighting could also be used in daylight as “fill in” flash. The new Ektachrome film could also be exposed to Photoflood lighting with a Kodak Wratten filter No.80B, but this cut the film speed down to 12ASA (ISO). Film sizes available in the

U.S.A. in 1955 were: Ektachrome Daylight film was

first sold in the U.K. in 1956 when the same film sizes became

available as in the U.S.A., except that 828 film was not supplied.

At the same time, kits of chemicals for processing the film became

available in 600ccs, 2 litres, and 3 gallon sizes. These chemicals

were known collectively as “Process E2”. The

1954 process then became known as “Process E1”.

The Process E2 processing

sequence was almost

identical to the 1954 Process E1 procedure (see

above). But it used a different First Developer formula and

had other slight differences, viz: In 1959, the E2 films were

listed in the U.K. “Kodak Dealer’s Catalogue”

for that year as E120, E620, and E135 (20 exposures). Unlike all Kodachrome films, Ektachrome films were sold without the cost of the processing included in the price of the film. Chemical kits for the original E2 processing solutions were still listed in the 1959 “Kodak Dealer’s Catalogue”. A complete kit of size 600ccs for processing 8 films cost 17 shillings i.e. 17s (85p). A complete kit of size 2litres for processing 26 films cost £2.5shillings (£2.25p). Ektachrome

Process E2 ~ Type F Film It was also possible to make

exposures in other light sources such as: For the 35mm user, it gave a choice of an alternative film to Kodachrome Type F film, although Kodachrome Type F was two thirds of a stop slower. Sizes available in the U.S.A.

in 1955 were: The film is not listed in the U.K. Kodak catalogues for 1956 or 1959. The U.K. “Kodak Professional Catalogue” for 1961 lists the film in EF120 and EF135 (20 exposure cassettes). Manufacture of Ektachrome Daylight Type and Type F films were discontinued in 1962, being replaced by Ektachrome X film. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

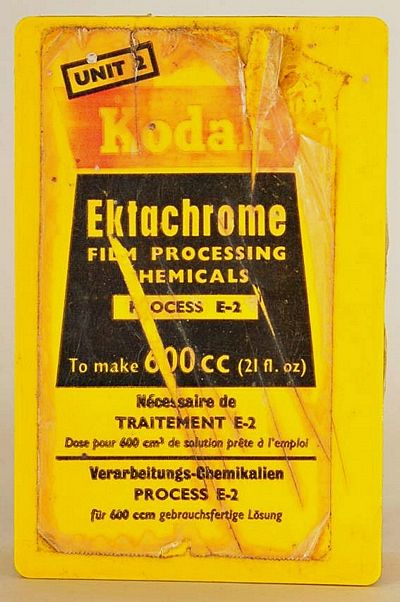

At the end of the 1950s, significant changes were made to the existing E2 roll and 35mm films, resulting in an 'Improved' Process E2 procedure with a modified First Developer and Bleach The Improved Process E2 chemistry was introduced in the U.K. from 1959 with 600ccs size kits, but this introduction occurred too late to be included in the “Kodak Dealer’s Catalogue” for that year. The separate chemical components were packed in two plastic boxes, one box, Unit 1, containing the two developers, and the other box, Unit 2 (see image, left), containing the Hardener, Clearing bath, Bleach, Fixer, and Stabilizer chemicals. With the “Improved Type” chemical solutions, the Clearing Bath and the Fixer were now separate solutions. A complete kit of “Improved Type“ E2 chemicals cost £1.2s.6d (£1.12p). The two Developers cost 12s (60p). The remaining chemicals cost 10s.6d (52p). All of these are late 1959 prices. The Unit 2 package shown alongside (left) is from an "Improved Type" processing kit, but dates to 1967, by which time Kodak had ceased to print “Improved Type” on the packaging. All Ektachrome E2 films could be processed in either the 'Original' or the Process E2 "Improved Type” kits, but the Improved Type chemistry gave a better colour rendering and clearer highlights. You could also put E2 films through E3 chemicals, as long as you then kept the two E3 developers specially for E2 films. At Art college Michael found it best to put several cut films through the process first to “ripen” the two colour developers, otherwise the freshly mixed chemistry resulted in a green cast on the film. Michael thinks it was 1968 or 1969 when Kodak finally stopped the manufacture of E2 chemicals. Process E2 ~ Unit 2 (see image). Michael Talbert purchased this Unit 2 part kit, along with the Unit 1 part, in January 1967, for his first attempt at processing colour film. All the enclosed chemicals were powders, except for the Stabilizer, and had to be mixed with water to make 600ccs working solution. The liquid Stabilizer was diluted with water to make 600ccs of working solution. The chemicals would (officially) keep for 8weeks, unused or partially used before needing replacement. This was a very conservative estimate and many users found that the chemicals would keep for at least another 4 weeks. Kodak enclosed a very informative 6 page instruction sheet with the Unit 1 part kit containing the First Developer and Colour Developer. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Process E2 'Improved Type' Procedure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Notes

The above process was also the sequence and timings for the later Ektachrome E3 process, described below. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| High Speed Ektachrome Film | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In 1959 an increased speed Ektachrome film was introduced, at first as 35mm film format in 20 exposure cassettes for exposure in Daylight. It’s speed was 160 ISO (ASA), over two stops faster than the regular Ektachrome film, (32 ASA). It was then the fastest colour film in the world. Next fastest was Super Anscochrome D, which was rated at 100 ISO (ASA) About a year later an artificial light type for 3200°K was made available as “High Speed Ektachrome Type B”, packed in 20 exposure 35mm cassettes, rated at 125 ISO (ASA). By 1963, 120 size roll films in both daylight and Type B films made their appearance.

Apart from processing High Speed Ektachrome using Process E2 into projectable colour slides (transparencies), it was possible to process High Speed Ektachrome as if it was a colour negative material, using the Kodacolor Process C-22. For examples, see below. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) |

.jpg) |

Two colour negatives taken in 1971 on Kodak High Speed Ektachrome 120 roll film exposed at 250 ASA (ISO) and then processed as negatives. The film was processed in Kodacolor C-22 chemicals at 75°F using a colour development time of 7 minutes. The remainder of the process was exactly the same procedure as when processing Ektacolor or Kodacolor negative films. The result is an unmasked colour negative with a pronounced magenta cast. The purpose of using High Speed Ektachrome film as a negative material was to make use of a speed increase as the film could be rated at 250 ASA (ISO). High Speed Ektachrome film processed normally as a transparency in E2 or E4 chemicals was rated at 160 ASA (ISO). The fastest colour negative film obtainable in 1971 was Kodak Ektacolor Professional film Type S rated at 100 ASA (ISO). As well as a gain of about 1½ stops in speed there was also a gain in contrast as shown in these pictures taken in sunlight. There is also a slight colour “cross over” of red shadows and if the pictures were darker, cyan highlights would appear. This “cross over” would show more in a less contrasty subject. It would have been better to use this technique in very dull, flat lighting than sunlight. The colour “cross over” shows most in the “old barn” picture as red shadows with no detail, and the highlights, (the geese), are “burnt out”. The negatives shown here were scanned and the positive prints were made digitally but only the colour balance of the prints was corrected, the contrast was not altered. This is to show how the prints may have looked in 1971. When making the prints in 1971 from the unmasked negatives, a blank piece of Kodacolor film, i.e. an “orange” mask, was included with the printing filters to make the negatives more like masked colour negatives. The original 1971 prints were made on Kodak Ektacolor Commercial paper and the strong magenta cast, otherwise resulting in very green prints, was filtered to neutral using Yellow and Cyan printing filters.

|

.jpg) |

.jpg) |

|

E2 Formulae from the British Journal of Photography

Annual 1980 First Developer.

Hardener. This is a weak

Stop Bath.

Colour Developer

Clearing Bath. This is a

Stop Bath.

Bleach

Fixer

Stabilizer

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||

|

In 1959, new Process E3 Ektachrome films came onto the market, in sheet and roll film formats. The new sheet films were named:- The roll films were identical to the sheet film emulsions. The Daylight Type roll film was introduced at the same time as the Daylight Type sheet film, in 1959. The Type B E3 sheet film was produced perhaps a year earlier (1958), but the Type B rollfilm was introduced much later, in 1971. Both rollfilms were replaced by Process E6 emulsions in 1976. |

||||||||||||||||

|

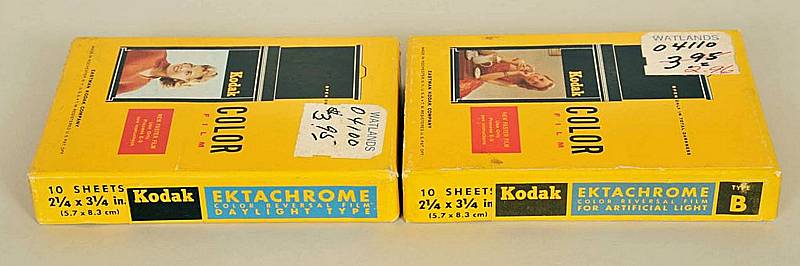

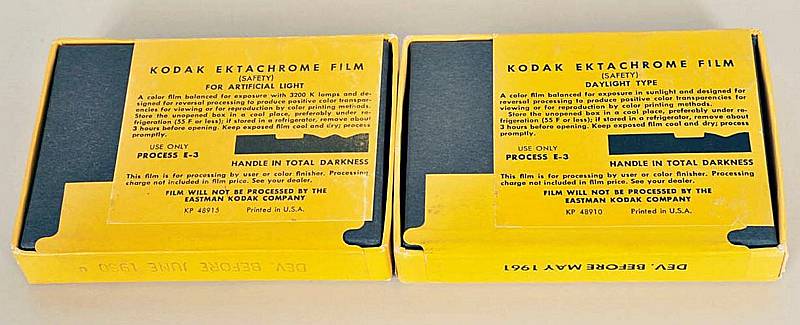

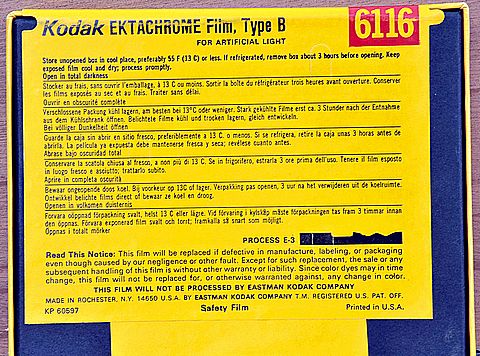

Two very early Ektachrome Process E3 Film boxes Daylight Type (LHS) and Artificial Light Type B (RHS) Size 2¼ x 3¼ inches and labeled with instructions to “only use Process E3” chemicals. |

||||||||||||||||

|

Same boxes as above. The Daylight film was rated at 50 ASA (ISO). The Type B film was rated at 32 ASA (ISO) for a ½ second exposure, but the speed then dropped as low as 10 ASA (ISO) for a 30 second exposure. For exposures as long as 30 seconds, Kodak CC 05 Magenta plus Kodak CC 05 Red filters were recommended to be used in the supplementary instruction sheet. |

||||||||||||||||

|

Same boxes as above. As can be seen, the expiry dates were: May 1961 for the Daylight type film (RHS) and June 1960 for the Type B film. It is likely that Eastman Kodak were manufacturing Ektachrome sheet film for Process E3 and Process E1 concurrently for a year or so. Here the Type B film has an earlier expiry date than the Ektachrome Process E1 Type B sheet film box illustrated above (January 1961). |

||||||||||||||||

|

Process

E3 Procedure An instruction leaflet was included with the 2 gallon replenisher chemicals giving information in tabular form of amounts of replenisher to be added after each process for single or quantities of the various sizes of sheet film, roll film, and 35mm film for both E2 and E3 processes. The two gallon size replenisher chemicals were intended for use with three gallon tank installations and not for continuous processing machines. The E3 Process was replaced by the E6 process about 1977 (began replacement around 1976) and by then most laboratories had installed the necessary equipment to process the then new E6 films. But there must have been a short period of time during the changeover when a few laboratories were running an E3 Process, an E4 Process, and an E6 Process ! By 1978 the E3 and E4 films still on the market must have been out of date or very near their expiry date. The new sheet films and roll films designed for the Process E3 were processed in exactly the same way as the Process E2 improved Type films (above), using the same bath sequence but employing a First Developer incorporating a different developing agent. In consequence, films designated for the E2 process, (roll films and 35mm films), had to be processed separately from the new E3 sheet and roll films by using separate First Developers and Colour Developers. All other solutions were common to both processes. However, it was possible to process small amounts of E3 film through E2 developers provided the process was operating within tolerance. Control strips of pre-exposed film were processed at regular intervals to check that the process was operating within limits as regard to speed of films, contrast, and fog level. In the USA. and the UK, both E1 and E3 processing chemicals and kits were sold concurrently for a time. Gradually E1 film and chemicals were phased out, being replaced by the new E3 films and processing solutions. It is said (BJ Almanac 1961) that the new E3 films gave improved definition and considerably better colour rendering of yellows and greens; also cleaner whites. |

Sufficient for 2 litres of solutions. |

|||||||||||||||

|

Ektachrome

E3 Daylight Type Sheet Film ~ 6115 The new Ektachrome sheet film was available in Daylight type, rated at 50 ISO (ASA), and also as an artificial light Type B version (3200°K), designed for exposure at times of ½second or longer with a nominal speed of 32 ISO (ASA). This sheet film was first available for sale in the USA in 1959, in formats from 2¼ x 3¼inches to 11 x 14inches, plus 5 sizes in square centimeters. The same emulsion was obtainable in rollfilm, EP 120 and EP 620. According to the BJ Almanac for 1960, E3 film was not available for sale in the UK in late 1959 and the same Almanac still gave information on the old E1 sheet film. A year later, E3 film was being sold in the UK and a 4 inch x 5 inch size box of 10 sheets of film cost £4 8s 2d in 1961. A box of equivalent size black and white film in 1961, say Plus X, cost about £1 4s (£1.20), but this was for 25 sheets of film. It should be remembered that the Chancellor, Selwyn Lloyd, announced a surcharge of 10% on Purchase Tax in July 1961, so the price of film would have risen during the latter part of the year. The Data Sheet for Ektachrome Daylight film, dated March 1959, states that the best colour rendering is obtained in clear or hazy sunlight, and gives filter suggestions for other light sources and guide numbers for blue flashbulbs and electronic flash. The speed of the film varied between 40 ISO (ASA) and 64 ISO (ASA). A supplementary data sheet, together with an instruction sheet of 4 pages packed with the film, stated the correct speed for each emulsion. Also printed on the supplementary data sheet was a filter suggestion for exposing the film with electronic flash tubes, usually a CC10Y filter = 10 Yellow. The emulsion number of the film was printed on the sheet and on the left side of the box. Also, it was embossed on each sheet of film. |

||||||||||||||||

.jpg)

|

.jpg) |

|||||||||||||||

|

To the left are shown various E3 film boxes, containing both Daylight and Type B film. These boxes date from the early 1960s; the Type B film box on the left is dated “February 1963”, the film being manufactured about March 1962. The “Dev. Before” date was originally printed on the back end of the box. Its position was changed to the front end in about June 1964, as is the case with the middle two boxes, and the box to the right hand side. |

|||||||||||||||

|

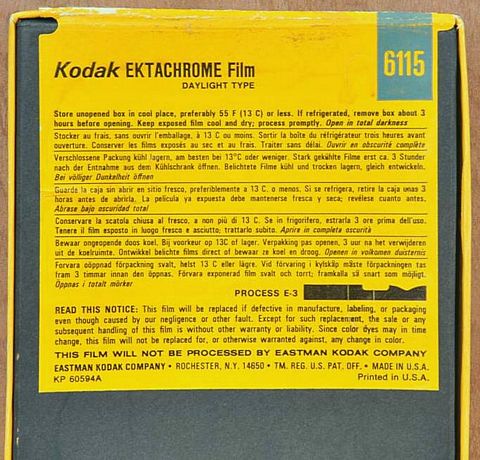

The rear label of all Ektachrome sheet film manufactured in the USA from early 1969 show only the storage recommendations, printed in several languages. The colour sheet film boxes were also of a different design (see: Ektachrome sheet film, dated March 1971, below). |

|||||||||||||||

|

Alongside are Kodak Ektachrome Process E3 film boxes from the late 1960s to the mid-1970s. The small box of Type B film (top of the 'pile') has its box sealing label fixed to the long side of the box. This change started in 1968 for Black and White and Colour sheet film but by 1970-71 Kodak had reverted to attaching the sealing label to the short side of the box for 4 x 5 inch and 5 x 7 inch sizes. The expiry date on the 2¼ x 3¼ inch Type B box is June 1971. This film was made and packed in the USA. It has a new design label and was probably manufactured about August 1970. Note the film numbers, starting in the late 1960s, were printed on the right hand side of the labels – 6115 for E3 Daylight film, 6116 for E3 Type B film. |

|||||||||||||||

| The Ektachrome box dated JAN 1970 (centre top box in the 2 rows of three boxes) has a starred sticker to the RHS, saying – ESTAR BASE. This was the trade name used by Kodak for “Polyester Plastic”. All sheet film Ektachrome Process E3 film was normally coated onto an acetate base, like Kodak Ektacolor Professional sheet film. This box of film is believed to be an experimental batch or a batch made for a special purpose. On the side of the box is the emulsion number, SO 263 21 B, meaning a Kodak product which was supplied to Special Order (SO), not to be on sale indefinitely, and could be withdrawn from the market at any time. Michael Talbert used this film in his 2nd year at Medway College of Art, and apart from the film having a slightly thinner base, it was identical to any other box of Ektachrome E3 sheet film. | ||||||||||||||||

|

Ektachrome sheet film, Daylight type and Type B for process E3. Eastman Kodak changed the design of their “Color Film” boxes in late 1968. This new design replaced the “picture in a dark slide” film box (see above) plus a new sealing label with storage recommendations printed in seven languages (as shown below). The description of the film was omitted from the label. The “Film Number”, which had always been printed on the left hand side of the box along the edge, together with the emulsion number, was also printed on the right hand side of the sealing label, 6115 for Daylight Type, 6116 for Type B. Both the illustrated boxes have a “Develop Before” date of March 1971. The sealing labels were increased in size and were now placed on the long side of the box for film boxes up to and including 5 x 7 inches. This practise had been done by Kodak Limited London on their black and white sheet film boxes in the late 1940s and from 1962 to 1965 - see black and white section. These label design changes were applied to Ektachrome camera sheet films as manufactured from late 1968. |

|||||||||||||||

|

|

|||||||||||||||

The larger (rear) label for the Eastman Kodak “Color Film” boxes (above) was short lived. By 1970 the label (see right) had reverted to being placed on the short side of the box for 4 x 5 inch and 5 x 7 inch sizes, but kept almost the same design, showing storage recommendations. Eastman Kodak have omitted the words “Safety Film” from the label. Above is shown a slightly different design for the top of the box, this one with a “Develop Before” date of January 1972. |

|

|||||||||||||||

| The author remembers the “large sealing” label boxes of film. He first encountered them in his last year at Art College using Ektacolor Professional Type S and Type L, Ektacolor Interneg and Ektachrome Duplicating film. At that time all Ektachrome sheet film (for cameras) sold in the UK was re-packed by Kodak Limited London into boxes that had “Colour Film” printed in red in a “blank” dark slide (see above picture of box dated JAN 1970). He's fairly certain that by 1970 all camera sheet film Ektachrome was imported from the USA without being re-packed, like the January 1972 box above. | ||||||||||||||||

| Ektachrome Professional 120 Roll Film ~ Process E3 (6115) | ||||||||||||||||

| This was the 120 size roll film version of Ektachrome 6115 Daylight type sheet film. The correct effective speed for the emulsion number stamped onto the film carton (03 348) was printed in red in the instruction sheet enclosed with the film. It could vary between 40 ASA/ISO and 64 ASA/ISO. The effective speed for film of this batch number was 50 ASA/ISO. | ||||||||||||||||

.jpg) |

.jpg) |

|||||||||||||||

.jpg) |

||||||||||||||||

| Ektachrome E3 Artificial Light Type B Sheet Film for 3200°K lamps | ||||||||||||||||

Front labels of Ektachrome Type B film manufactured in the USA and then repacked in the UK. The boxes are of 4 x 5inch Ektachrome Process E3 Type B film for artificial light (3200°K – 3400°K), with 'Develop Before' dates of January 1970 and November 1968. |

Rear label of Ektachrome Type B sheet film for process E3. As the label shows, this film was manufactured by Eastman Kodak in the USA, but then sent to the UK to be repacked and labelled by Kodak Limited, London. |

|||||||||||||||

| The practise of

re-boxing film imported from the USA began in 1965, but by 1970

Kodak in London were again importing colour film from Eastman

Kodak, Rochester, USA, in original boxes, as pre-1965. The Ektachrome

film box, daylight type, with a “Develop Before” date

of January 1972 (see further above) is one such that has not

been repacked. As far as is known, Ektachrome Daylight Type, Ektachrome Type B, and Ektacolor Print Film were the only films to be imported and repacked in this manner. |

||||||||||||||||

|

Artificial Light Type B E3 film was available for sale in the USA from 1959 in sheet film format only and in the same sizes as the Daylight Type E3 film. It was sold for the first time in the UK in 1960. Each box contained a general instruction sheet and a supplementary data sheet. Similar to the Ektachrome E1 film (see above), the supplementary data sheet gave the actual speed of the film plus filter recommendations for correcting the colour balance when the film was exposed at longer times than ½ second. The general instruction sheet gave exposure indexes for:

In the description of exposing sheets of Type B film designed for the Ektachrome E1 process (see above), the photographer was advised to increase exposure by between ½ stop and two stops, due to the reciprocity failure of the film. A different method of calculating the exposure was used with Ektachrome Type B E3 film. Typical Supplementary Data sheet for a batch of Ektachrome Type B Process E3 sheet film

*

colour balance Normally, the correct exposure was found by setting the exposure meter at the middle ASA speed i.e. 20 ASA, and taking a reading. If the exposure time thus calculated was much greater or much less than 5 seconds, and a different speed given in the data sheet related to this time, this different speed was used to re-calculate the exposure. For times much beyond 30 seconds, say over 60 seconds, a trial exposure definitely had to be made, as it was likely that the film speed would need to be decreased even further and the colour balance corrected with a higher strength filter than CC 20G. Example: Michael Talbert exposed many sheets of Ektachrome Type B E3 film and in his experience it was always best to take a “test" shot first, which would also tell the particular colour balance of the processing chemicals. In the above example, if the E3 process was tending towards a magenta balance, this might “cancel out” the results from a CC10 Green filter, making the finished transparency still slightly magenta despite exposing with the equivalent of a 15 Green filter on the lens. Thus, the "test" would give guidance of the likely need to use a stronger correction filter than CC15 Green. Other common variables which might alter the colour balance of the processed transparencies include:

BUT....given the correct exposure and processing, this film was capable of producing outstanding results, far better than that of any rollfilm or 35 mm film designed for Process E2. Ektachrome E3 Process sheet films were replaced by Ektachrome E6 sheet films in 1976. |

||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Process E-4 was introduced by Eastman Kodak Company in 1965 as a faster reversal process operating at 83 – 87°F for machine processing of amateurs’ Ektachrome films. Unlike Process E-3, there was no need for re-exposure of the partly processed film to light for reversal; instead, reversal was accomplished by chemical fogging in the E-4 Colour Developer. Films suitable for processing

in E-4 (in 1973) were: Other sheet film Ektachrome, 6115 and 6116, Ektachrome Duplicating Film, 6119 and 6120, and Professional roll films, 50 ASA, and 32 ASA, could not be processed in E4. These films could only be processed in E3. As the films listed above were

originally designed for processing at temperatures of 73 –

77°F, (Process E-2), emulsion reticulation would occur when

processing these films at higher temperatures. Therefore, two

additional baths were required, The Pre–Hardener bath

contained two powerful hardening agents, (i) Formaldehyde and

(ii) DMTF, 25 – dimethoxytetrahydrofuran. The E-4 Colour Developer contained TBAB – tertiary butylamine borane. This chemical enabled the undeveloped parts of the film, having been developed to a negative image in the First Developer, to react in the Colour Developer to form a positive image. TBAB is very toxic, and the chemical had to be handled with great care. Kodak supplied the chemical as one part of the Colour Developer, and Colour Developer Replenisher, in pellet form, to reduce any chance of inhaling any dust or powder from the TBAB when mixing the Colour Developer or it’s Replenisher. Again, the 3 gallon instruction leaflet gave precautions in handling and mixing the components of the separate parts of the Colour Developer/Replenisher. If the Colour Developer was mixed from separate chemicals, as to the formula, TBAB could be omitted. The films were then given a reversal light exposure after step 5, in the same way as in the E2 and E3 procedures, before placing the films in the Colour Develper. Although the process was initially designed for use in large tank installations and continuous processing machines, it was possible to use the E-4 process in small amateur developing tanks. Small volume kits of chemicals were made available in 1 quart size (US), and 600ccs size (UK) by the end of the 1960s. Processing

Procedure for E-4 (i) large commercial tanks (ii) amateur processing

tanks

Notes:

(ii) Processing procedure for small tanks, 2 litres or less. This was the processing procedure for the Kodak (UK) amateur E-4 kits.

Notes:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The Ektachrome E-6 process began to supercede Process E-4 from 1976. Kodak stopped making Ektachrome X (a process E2 film) about 1978, replacing it with Ektachrome 64 film for the (new) E-6 process. Thereafter, all previous Ektachrome films could only be processed if sent to a laboratory still providing the lower temperature Process E-4 (or the obsolete E-2). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

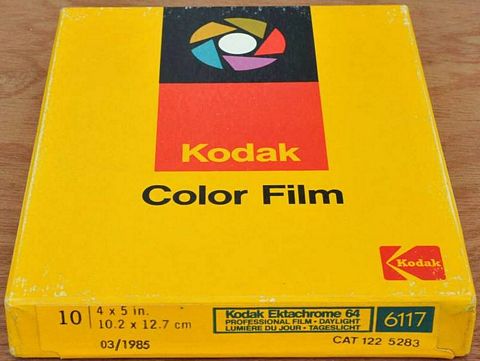

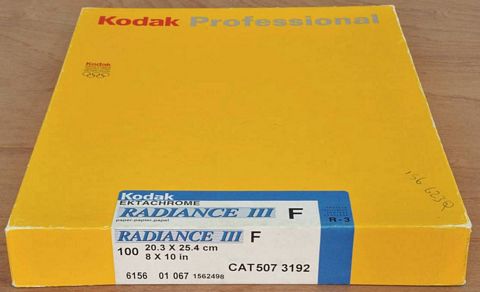

| Ektachrome Professional 64 This was one of the first E6 sheet films to be marketed in the USA in 1976 and then in the UK from 1977. The speed rating could vary from 50 ASA (ISO) to 80 ASA (ISO) and the actual speed of the film for each batch was given in the instruction sheet enclosed in the film box. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

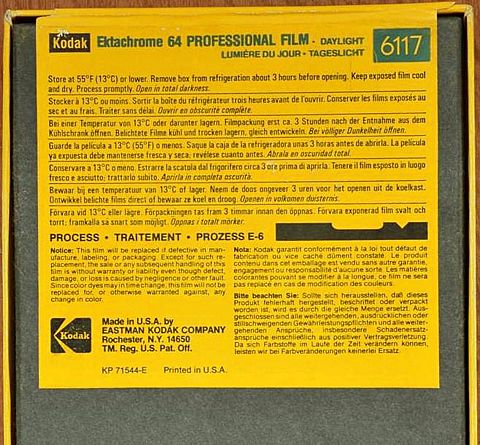

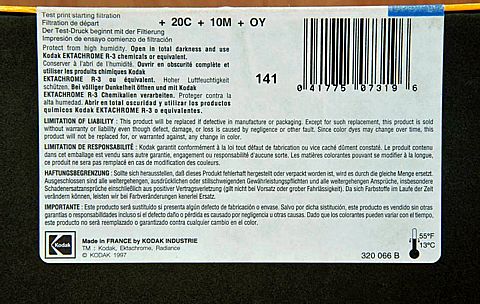

A box of 5 x 4 inch Ektachrome Professional 64 Daylight Type Film for Process E6 This box has a "Develop Before" date of March 1985. The rear label (see right) shows storage instructions in seven languages. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

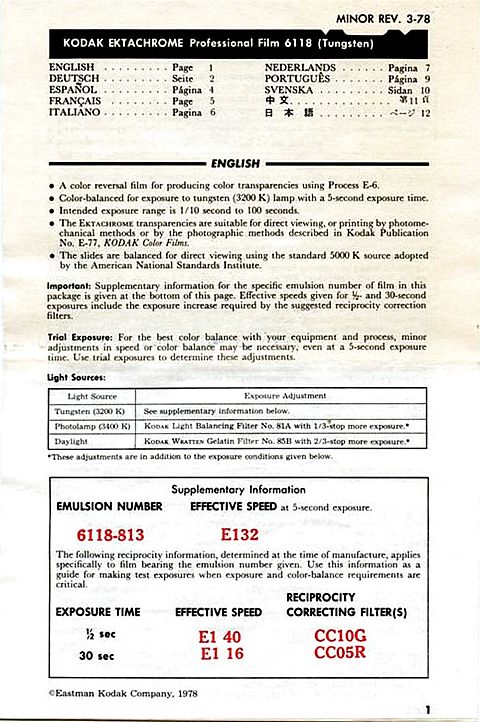

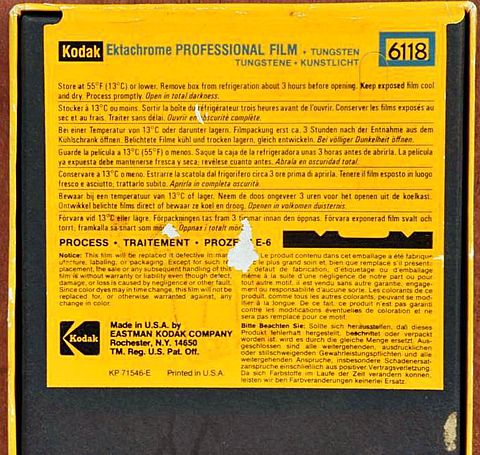

Ektachrome

Professional film 6118 The 6118 film was designed for exposures from 1/10 second to 100 seconds. It’s speed when exposed using 1/10 second could vary from 32 ASA (ISO) to 50 ASA (ISO). An instruction leaflet dated March 1978 was enclosed in the film box (see below) stating a speed of 40 ASA (ISO) for use at ½ second, and a speed of 32 ASA (ISO) at a 5 second exposure. For critical use a trial exposure could be made, especially if the exposure estimated was over 20 seconds. In this case an exposure reading would be taken with the meter set at 20 ASA (ISO). For exposures over 40 seconds, it was essential that a test exposure was made, and this would show if any extra filtration (including the CC 5 red filter) was needed to correct the colour balance. For an estimated exposure of about 100 seconds, 10 ASA (ISO) might have been a good starting point plus a CC 10 Red filter. Ektachrome Professional film 6118 Tungsten was replaced by Ektachrome 64T Professional film in 1989. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The rear label shows the “Code Notch” and storage details. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektachrome

Professional 100 film for daylight, Sheet and Roll Film Other features: By 1985 an 11 x 14 inch size sheet film was available as well as a 220 size roll film, 35mm and bulk 35mm in 100 foot rolls. In the late 1990s the sheet film number was changed to 7058 with the same catalogue numbers. Other Ektachrome camera films were introduced during the 1990s incorporating Kodak's T grain for much finer grain, but Ektachrome 100 Professional film continued to be manufactured using traditional technology. A part description from the

UK Kodak “Professional Products Profile” catalogue

for 1999 reads: By 2003 the film was available in 4 x 5 inch sheet film, 120 roll film, 35mm cassettes, and bulk 35mm. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

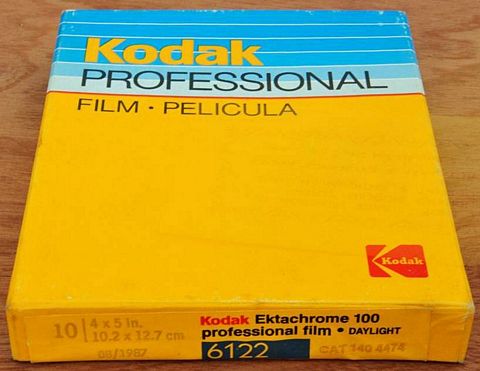

Front of a box of 4 x 5 inch Ektachrome 100 Professional film with a 'develop before' date of August 1987 |

The rear label of a box of Ektachrome 100 Professional sheet film. It shows storage information and a “Code Notch” diagram. One of the first labels on which a thermometer icon was used to denote storage temperature (below 55°F, 13°C). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

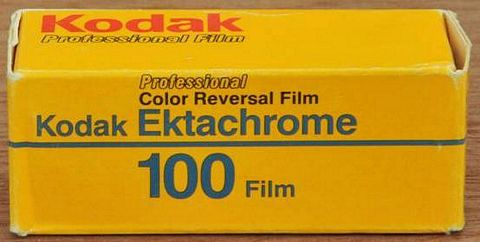

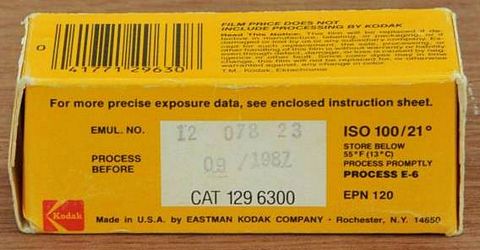

Ektachrome 100 Professional in a 120 roll film size Above is a 100 ISO (ASA) speed film and below is the 200 ISO version. |

Ektachrome 100 Professional 120 film with a 'develop before' date of September 1987. The 200 ISO film below has a 'develop before' date of June 1988. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Kodak

Ektachrome E6 Processing Kits Kodak Developer

Kit Process E6 Thanks to the Canadian ebay seller 'thrifttwins' for his permission to show the following images of an Ektachrome film E6 processing kit dating from 1979 for processing any E6 films. It combines the 1977 innovation of including two 473 ml units each of First Developer and Colour Developer, plus one 473 ml unit of all the other associated chemicals. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) |

_cr.jpg) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) |

.jpg) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Kodak

Hobby Pac Colour Slide Kit for Process E6 This kit of chemicals was intended for amateur photographers to process any E6 film in small developing tanks at temperatures from 96°F to 110°F. This was the recommended temperature range for best results. However, it was also possible to obtain acceptable results from processing films at temperatures from 70°F to 95°F. The following processing sequence gives times for 96°F (35.5°C) using small capacity tanks holding half a litre of solution.

Notes:

As far as is known, the Hobby

Pac kits were discontinued in the late 1990s. In the UK in 1998

a 3.8 litre kit was obtainable for E6. The volume changed

to 5 litres in 1999, comprising of six solutions By 1992 the formaldehyde was removed from the E6 Stabilizer and the bath was re-named “Final Bath” or “Final Rinse”. E6 films were hardened in the Conditioner bath, now re named "Pre-Bleach”. The formalin was locked into the solution chemically and was released onto the film only when needed, thus eliminating the irritating smell of formalin. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Processing

Procedure for E-6 Although, at its very highest temperature of use, Process E-4 was only 10degF lower than Process E-6, an important inclusion within Process E-4 (compared to Process E2) was a 85°F Pre-Hardener stage, which toughened E-2 film emulsion layers sufficiently to withstand E-4 processing temperatures. You couldn't process E-2 Ektachrome films in Process E-4 without putting them through this Pre-Hardener step first. Since Process E-6 did not include a Pre-Hardener, because E-6 films were intrinsically designed to tolerate the 38°C E-6 processing temperature, any E-2 film put through an E-6 process would be liable to irretrievable emulsion damage; the emulsion might even separate completely from its base. For advice on how to process out of date E-2 films, see the following section. The following table provides a summary of steps for Process E-6 in a typical amateur 600ml processing tank. The times shown include a 10 second drain time at the end of each step. If your tank is not a daylight-loading model, you should load it in complete darkness, but for convenience of filling, emptying and agitating with solution, it is acceptable to remove the lid of the tank at the end of step 3. For a commercial large tank

replenished system or continuous processor, the following times

applied:

Notes:

The British Journal of Photography Annual for 1985 gives advice for processing E-6 film at 32°C (rather than the official 38°C), being the lowest temperature recommended. The BJPA text says that processing below 32°C “the permeability of the emulsion diminishes too greatly to permit adequate exchange of solutions through the gelatin”. In other works, below 32°C, the gelatin is too cold to let the flow of chemicals through to work on the bottom emulsion layers (but see the following section, where Photo Technology claimed processing to be possible down to 20°C).

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

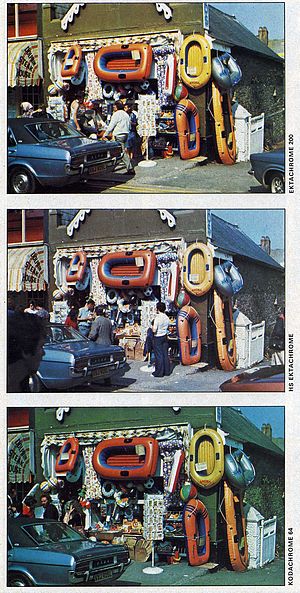

Amateur Photographer test of Ektachrome 200 for

Process E6 (January 18th 1978) The new Ektachrome 200 has significantly improved grain characteristics while offering a 1/3stop increase in speed over the former E4-process High Speed Ektachrome (160 ASA). It has improved colour reproduction with better separation of subtle hues of the same colour. The new film is not only sharper than High Speed Ektachrome, but seems to have lost the traditional blue/green bias. The makers also say that the new product gives excellent results when push-processed by one f/stop to obtain an effective film speed of 400ASA. This is one of the most useful advantages of this new film. Fast film speed ratings do, however, come with certain disadvantages - something has to be slightly sacrificed in order to achieve the speed. You'll still have to go a long way to beat the colour saturation and sharpness of Kodachrome 25, but the new film isn't far off the quality of Kodachrome 64. Professional users of the new Ektachrome 200 claim that the Professional version shows better flesh tones, neutrals, greens and browns; especially better brown tones found in wood grain and other "rich" surfaces. Professional films, though, are aimed at a specific user and therefore these films must be carefully stored in refrigerated conditions. The capacity of a film to faithfully reproduce colours can change over a period of time, so the new films aimed at the amateur take this into consideration. Amateur users have nothing to worry about if they use the film before the expiry date on the carton. However, it is reported by some users to be less forgiving, storage-wise, than High Speed Ektachrome. Processing services for Kodak Ektachrome films of the E4 process will continue to be available for an undetermined length of time. This will be until the manufacturer feels that photographers have had sufficient time to finish all their E4 films and have gone over to the new E6 films. Amateurs who wish to process their own new E6 Ektachrome films can obtain an E6 processing kit which will make 600ml of solution. At the moment the new Ektachrome 200 is available only 35mm cassettes viz: 20 exposures for about £1.58 and 36 exposures for about £2.50. In our user tests of the films

compared here, three cameras were used - a Nikkormat FTn, a Canon

AT-1 and a Fujica ST705. All three of the films were then sent

to Kodak for processing to obtain the best results. The advantage

of the new 200ASA film is only slight when compared to the former

160ASA variety, but when used at 400ASA it really does become

more important. This means that a faster shutter speed may be

used to stop action or alternatively a smaller aperture may be

used for increased depth-of-field. Due to reciprocity characteristics, some small amount of film speed is lost when using the new films with electronic flash due to the extremely short exposure time. This is also the case with exposures longer than about 1sec. The reversal part of the E6 process is a chemical one, so the film spiral need not be removed from the developing tank and held up to a bright light; in fact reversal is not complete by this method with the new films. All the processing chemicals are liquids and there are seven of them; first developer (6min), then first wash (2 min); reversal bath (2min); colour developer (6min); conditioner (2 min); bleach (6min); fixer (4min); final wash (4min) ; and finally the stabiliser (½min). Total time 32½min. The first developer temperature is the most critical for maintaining correct results. This should be 38.0 degrees C; +/-0.3 degrees. This is not easy to maintain, but it does affect density for effective film speed. To push process the film for a 400ASA rating, the only step required is that the first developer time must be increased by about six to eight minutes. Then carry on as usual. However, remember that this procedure of up-rating films increases contrast and grain and decreases exposure latitude. If you're really bold, or need to save a film under-exposed by two stops, then try extending the first development time to around 11½min. So when it comes down to colour rendition, grain, sharpness and exposure latitude, which film really scores? The short answer is that Kodak deserve a big pat on the back and a hearty "thank you" from photographers, because the new Ektachrome 200 seems to take the honours on all points. This is taking into consideration that Kodachrome has had traditionally better colour saturation and grain than the E4 High Speed Ektachrome. Gone is the traditional Ektachrome habit of changing flesh tones in shade areas to a cadaverous blue. But now with the extra speed of the 200 film and careful exposure, this new film is a winner. Keeping Kodachrome 64 on the market ensures a good medium speed transparency film, but I would guess that the majority of photographers will choose between either the sharpness of Kodachrome 25 or the speed of the new Ektachrome 200. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The three upper shots were taken by direct summer sunlight. The left one was taken on the new Ektachrome 200 and has not only better colour saturation, but a "richer" type of colour reproduction. Colours are more accurate compared to the real flowers. The middle shot taken on High Speed Ektachrome (160ASA) and shows a bit of the traditional blue bias. The reds are slightly more washed out looking and the difference between the various hues of red are not as distinct as in the new Ektachrome shot. In the shot on Kodachrome 64 (right) the colours appear to have an overall green'ish bias. This shot has slightly more exposure so all colours appear lighter and brighter, though not quite as accurate as those seen in the new Ektachrome shot. Flesh tones reproduced in the lower pictures are more natural, yet 'rich' at the same time in the far left example on the new Ektachrome 200 film. The exposure for all three shots was exactly the same. Compared with the High Speed Ektachrome shot in the middle, the new film shows not only better colour saturation in the highlight areas (note the deeper green grass), but also in the shadow areas (note the whiteness of the blouse). The example taken on Kodachrome 64 (on the right) still has the slight overall green bias, but you will probably be able to notice that this shot appears slightly sharper due to the finer grain of this lower speed film. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Colour saturation and accuracy may be seen perhaps a bit easier in these three examples. The top one was shot on Ektachrome 200. The colours are more true-to-life than in either of the other two examples. The Kodachrome 64 shot (bottom) appears slightly sharper due to its lower film speed, but shows a slight greenish colour bias. The middle shot, taken on High Speed Ektachrome, still exhibits some of the traditional blue/green colour bias for which Ektachrome was noted. This, thankfully, is gone now and even many Kodachrome 64 users will probably switch over to the new Ektachrome 200 for its slightly better colour rendition even though it is marginally less sharp. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

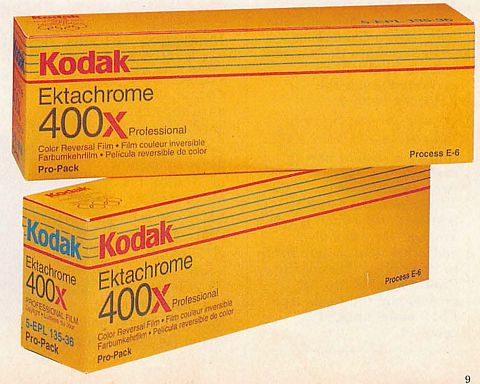

| Ektachrome 64X, 100X and 400X Pro (Spring 1992) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The following has been extracted from Amateur Photographer magazine for 22nd February 1992. It appeared in a series of announcements within a 3-page News section report from the PMA 92 trade fair held in Las Vegas. (PMA = Photo Marketing Association) That little X-tra Once again Kodak is adding

that little bit X-tra to its film range with its new Ektachrome

400X Pro. Designed for fast action shooting

in low light, the film is the first ever 400 reversal film for

professionals. The latest addition to the Ektachrome family will appear (UK) in March in 35mm with the 120 format version out in April (all refers to 1992). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Processing

Out-of-Date E-2 (and E-3 / E-4) films Possible Options are:

Photo Chrome 6 Instructions

Notes for Chrome 6:

In Conclusion: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Type R Paper from

1955 (becoming

Ektachrome Paper in 1958) In 1954, the US Supreme Court ruled that the Eastman Kodak Company were required to release technical information on the printing and processing of Kodacolor films and Kodacolor paper. This ruling also extended to the making of colour prints produced directly from Kodachrome and Ektachrome transparency films. At that time, Eastman Kodak were making Kodachrome prints and Kodachrome enlargements from colour transparencies in any size film format up to 5 x 4 inches. Print sizes ranged from 2¼ inches x 3¼ inches to 8 inches x 10 inches. It was possible that these prints were made on a white pigmented cellulose acetate base material similar to the Eastman Kodak “Kotavachrome” prints ten years earlier. In the early 1950s, Eastman

Kodak were also making colour prints from 35mm transparencies

by first making an internegative on Kodacolor roll film, and

then printing this internegative onto Kodacolor paper. At this time, there was no actual film designed for use solely as a colour internegative film, apart from certain Eastman Color negative films being used in the Motion Picture industry. Kodak Color Print Material, Type R, originated in 1955 jointly from Kodak Pathe, at Vicennes, France, and Kodak Ltd. Harrow, UK. It was first manufactured in roll form only, in France and the UK, solely for use in Kodak processing and printing laboratories in the UK and Europe for making reversal colour prints directly from amateur photographers’ transparencies, but was later manufactured by Eastman Kodak at Rochester, New York. Eastman Kodak marketed the product in roll and various sheet sizes in the USA to colour laboratories and professional photographers. Although 'Type R' was sold in the USA to professional photographers, and possibly amateur photographers in the late 1950s, there is no obvious evidence that the paper was marketed or distributed to anyone in the UK other than colour laboratories operated by Kodak Ltd before 1965. The paper is not listed in the UK Kodak Professional Catalogue for 1964 – 1965. The paper was balanced for about 3200°K, and when making prints with an enlarger the colour balance was altered by the use of, at first, Kodak Color Compensating filters, and later Kodak Color Printing filters. Enlargers equipped with colour heads could also be used, such as, Agfacolor or Chromega colour heads. It was recommended by Kodak that the enlargers were fitted with an ultra violet filter, such as a Wratten 2B, and an Infra Red cut off filter. The Infra Red filter prevented extreme red casts in the print requiring a very high cyan filtration leading to lengthy exposure times. A first trial filtration given by Kodak was “10 Yellow plus 30 Cyan” (10 — 30). The layer arrangement was identical to Kodak Color Print Material, Type C, with the red sensitive layer on top, the green sensitive underneath the red, and the blue sensitive layer at the bottom of the pack. Unlike the material used for making Kodachrome prints, the emulsions for 'Type R' were coated onto a paper byrata–coated base. The paper was about twice as thick as Kodak single weight Bromide paper made in the UK in the mid-1950s (Bromide WSG 2S). Processing

Type R Paper, using Kodak Color Print Process P-111, from 1955 In 1960, a Kodak Color Print Processing Kit for Process P-111 could be obtained in a 3½ US gallon size. This kit contained the chemicals to make the six processing solutions, the Stabilizer being made up by the user to the Kodak formula. Separate packs of the six solutions were also available in sizes of 3½ US gallons, 10 US gallons, and 25 US gallons of each processing solution excepting the Stabilizer. A First Developer Replenisher, Process P-111, and a Color Developer Replenisher, Process P-111, were available to make 5 US gallons and 25 US gallons of each solution. This sequence is the procedure for Tank Processing, in 3 gallon tanks or larger, using the Kodak Color Print Processing Basket. Times may have been different for continuous processing machines.

Total wet processing time i.e. excluding Reversal Exposure and Drying = 74¼ Minutes Notes:-

From 1958, Kodak Color Print Material Type R, became known as “Kodak Ektachrome Paper”. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektachrome

Paper, from 1958 Up to 1965, Ektachrome Paper

was exposed and processed in exactly the same way as the previous

“Type R” material. There seems to have been no change

in the product apart from its name. Availability

of Kodak Ektachrome Paper in the USA in 1960 Only three sheet sizes were “stocked”; other sizes may have been subject to delivery delay or had to be ordered specially. Machine

Printing Kodak Ektachrome Paper and Processing in Ektaprint R

Chemicals; 1963 – 64 It is thought that, in 1963, there was no Kodak colour printer designed especially for making prints from transparencies. By 1967 the 'Kodak Roll Printer Model 5B-K' was available for use with Ektacolor and Ektachrome papers. A processing sequence for rolls of Ektachrome RC (Resin Coated) in the 'Kodak Continuous Color Print Processor Model 4R-3', introduced in 1964, processed at a speed of 1½ feet per minute at 85°F gave times of 3½ minutes in each solution and washes apart from the Stabilizer (2 minutes) and 'Spray Wash' (9 seconds). The processing sequence appeared in the 1969 instruction sheet 'How to use Kodak Ektaprint R chemicals' reproduced below on page 4 of the instruction sheet dated August 1969. The original process in 1964 for the Kodak Model 4R-3 may have included a 'Pre-Wet' step and a wash between the Hardener Stop Bath and R3 Bleach. The Ektachrome paper in 1964 did not have a Resin Coated base and would have required the 'Pre-Wet' step and longer washing times, but the speed of processing the paper and the temperature were the same. Ektachrome paper coated onto a Resin Coated base became available from 1969. The Ektaprint R process was introduced in 1964 replacing the old P-111 process which had been used with Ektachrome paper and Kodak Color Print Material Type R since 1955. Ektaprint R was a much faster process than P-111, operating at 85°F. It seems that the new Ektaprint R chemicals and process temperature were designed to work with the (then) new Kodak 4R-3 processor. As far as is known, Eastman Kodak never manufactured a colour print processor to work with Ektachrome paper and the P-111 process chemicals, but there may have been processors made by other companies or by colour processing labs specifically for the P-111 process. It is quite likely that the formulae of some of the components of the P-111 process remained the same within the new Ektaprint R process. Before 1964, rolls of Ektachrome paper could be wound onto Kodak Processing reels, taking widths of 3½ inch, 5 inch, and 8 inch wide paper, and processed in a P-111 3½ US gallon tank line. There were two Bleach chemicals, Ektaprint R Bleach, and Ektaprint R3 Bleach. In 1964 Ektaprint R Bleach was available in 3½, 10 and 25 US gallons. The Ektaprint R R3 Bleach was available in 25 US gallon size only. The R3 Bleach may have been made specifically for continuous colour print processors. Also in 1964, the 'Formalin Fixer' chemicals were common to both the Ektaprint R and P-122 processes as well as the later (1965) Ektaprint C process. (References: Eastman Kodak “Products for the Professional” catalogues 1964, 1965, 1968. Kodak Color Data Guide 1966. Eastman Kodak Stores, Inc catalogue 1965. Kodak Ektaprint R instruction sheet 1969). Kodak

Ektachrome Paper in the UK The Ektaprint R chemicals had to be imported from the USA along with the paper and were available in 3½ US gallon and 10 US gallon of each of the chemicals to make working strength solutions. The Ektaprint R 'Formalin Fixer' had replaced the P-111 'Hardener Fixer' and there was now an 'Ektaprint R Stabilizer'. There were also chemical components for replenishers for the First Developer, Colour Developer, and Formalin Fixer to make up 5 US gallons of replenisher for each solution.There were no Ektaprint R kits; the process was designed for large colour laboratories and D&P processing stations either for use as a 3 US gallon tank line or the quantity of 10 US gallons or more in continuous processing machines. The 'Kodak Trade Circular' for 4th January 1965, printed in December 1964, gives revised prices for all of the six P-111 chemical components. It is thought that the paper and chemicals were listed in a UK 'Kodak Finisher' catalogue, distributed only to large photofinishers, and Ektachrome paper and Ektaprint R chemicals were included for the first time in the 'Kodak Trade Circular' for March 1966, hence being termed as a 'new product' in that particular Trade Circular. Kodak Ektaprint R chemicals were included in the 'Kodak Professional Catalogue' for 1966 - 67 (catalogue dated January 1966), but Ektachrome paper was omitted. In the catalogue under the heading 'Ektaprint R Processing Chemicals' there is the note: “For processing Ektachrome Paper. For further details apply to Professional Sales Division, Kodak House, Kingsway, London WC2”. An equivalent Professional catalogue for 1968 – 69 lists the chemicals without this additional note. In 1966 – 67 the Formalin Fixer became common to the Ektaprint C process and the Ektaprint R process. The solution was available as 'Ektaprint Formalin Fixer', to make up 3 UK gallons, and as replenishers (Ektaprint Formalin Fixer and Replenisher) to make up 8.8 UK gallons and 22 UK gallons. By this time (1967), most of the Ektaprint R solutions were being sold as 3½ and 25 US gallon components except for the two developers, which were sold as to 3½ and 10 US gallons of working strength solution, and 5 and 25 US gallons of Replenishers. All the Ektaprint R chemicals were manufactured in the USA, except the Ektaprint Formalin Fixer, which was made in the UK. (References: Kodak Professional UK catalogues, 1966 – 67, 1968 – 69. Various Kodak Trade Circular booklets, 1965 – 67. Eastman Kodak Professional catalogue, 1969 - 70). Processing

Ektachrome Paper using Ektaprint R, from 1965

Total wet processing time: 48¼ minutes. Notes:

Ektachrome Paper was replaced by Ektachrome RC Paper in 1969. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektachrome

RC Paper, from 1969 By August 1969, Ektachrome

RC paper was available in roll sizes from 3½ inches

in width to 11 inches in width. Processing

Ektachrome and Ektachrome RC Papers using the Kodak H11-L and 16K Rapid Processors, 1965 to 1973 Processing in the H11-L and

16K Rapid Processors consisted of partly using Ektaprint R

chemicals and partly CP-5

chemicals.

Notes:

Processing Ektachrome RC Paper using Ektaprint R, 1969 to 1973

Notes:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Below is shown an Ektaprint R instruction sheet of 7 pages as would have been enclosed in the “First Developer” chemical component to make up 3½ US gallons of solution. It dates from August 1969 and was the first instruction sheet published with the new reduced process times for Ektachrome RC (Resin Coated) paper. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) |

.jpg) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) |

.jpg) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg) .jpg) |

The final wash time was reduced dramatically from 10 minutes to 3 minutes. There was no “Pre-Soak” step, and the wash between the Hardener-Stop and R3 Bleach was omitted. The reduction in wash times was due to the water resistant Resin Coated base which minimized the absorption of water and processing chemicals. The instruction sheet mainly refers to batch processing in 3½ US gallon tanks, but gives process times for two continuous colour print processing machines. Ektachrome RC paper was the second colour printing paper to be manufactured with a resin coated base. .jpg) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Chronology: Ektachrome Papers Manufactured in the USA from 1973 to 1990

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Chronology: Ektachrome Papers used in the UK,

imported from France and USA; 1973 to 1990

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

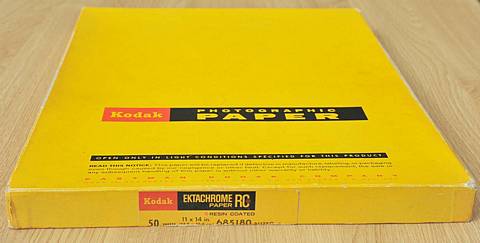

| Ektachrome RC Paper Type 1993 (in the USA from

1973) In the USA, Kodak Ektachrome RC paper Type 1993 replaced Ektachrome RC paper in 1973 and a shortened version of the “Ektaprint R” process was introduced in 1973 as “Ektaprint R-5" with fewer solutions and washes. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

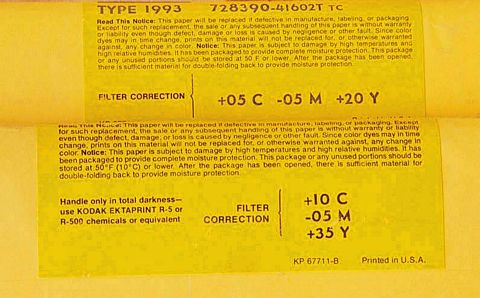

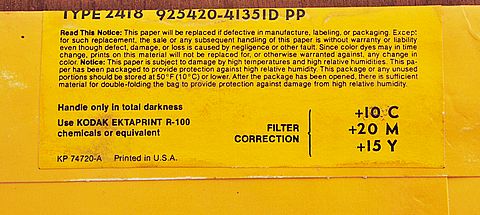

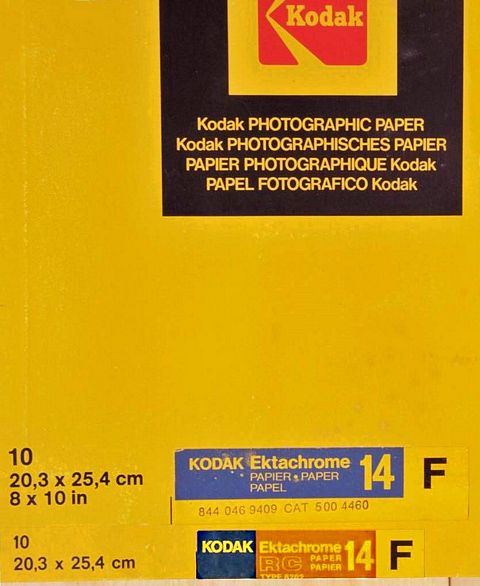

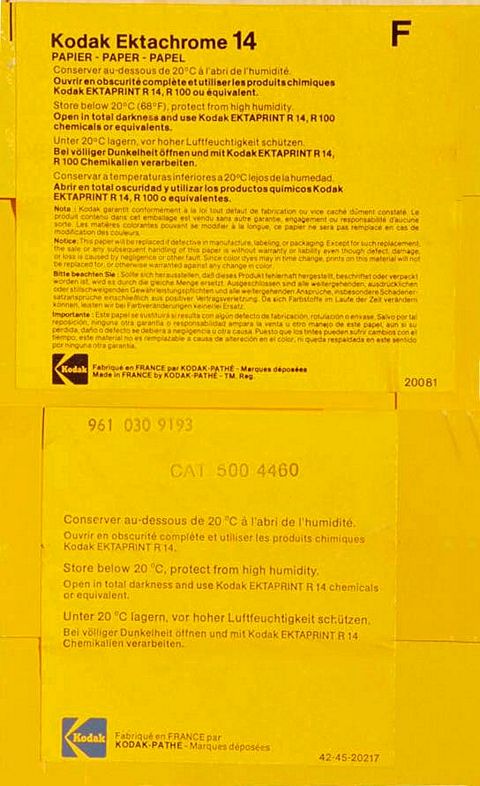

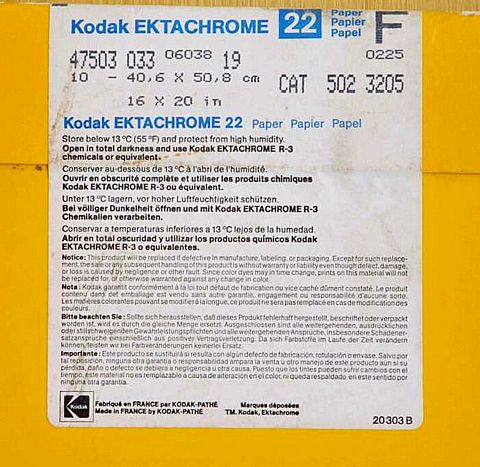

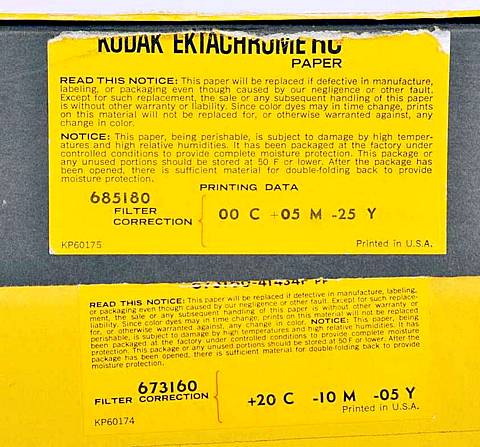

| Above are shown two front labels from Ektachrome RC paper, Type 1993. The top label dates from 1975 and the other label dates from 1973-74. Ektachrome RC 1993 paper was compatible with the earlier Ektaprint R seven-chemical bath process as well as the later Ektaprint R-5, five-chemical bath process. The “F” signifies a glossy surface, and the paper was also obtainable with a Silk surface, coded “Y”. | Above are the back labels to the same Type 1993 packets. The top label is of the earlier packet of 1973-74 and shows the 1993 designation. The later label now includes the processes where the “R-500” replaced the earlier “Ektaprint RD” chemicals for the Kodak Rapid Processors. Both packets show the “Filter Correction” for changing between different batches of paper. Note the high Yellow filter correction on the later packet. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Processing Type 1993 using Ektaprint R-5, from 1973

Total Time: 21½ minutes. Notes:

Ektachrome RC Type 1993 paper could be dried in a drum dryer with the emulsion side out, or rolls of paper were fed through hot air dryers. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektachrome

2203 Paper, in the USA from 1977 To begin with it was available in roll form only, in “Y” silk surface, but by 1980 it had fully replaced the 1993 paper and was obtainable in sheets and rolls in “F” glossy surface, and “J” smooth high lustre surface. Ektachrome 2203 was designed for processing in (then new in 1977) Ektaprint R-100 chemicals for large continuous processors working with roll paper. Ektaprint R-1000 chemicals were made available in small quantities for processing sheets of paper in drums and tube type processors. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektachrome 2203 was principally used for “Print from Print” viz: a service mainly for amateur photographers where only the original print (not the negative) was needed to make copies or re-prints. The original print was copied by reflection directly onto the Ektachrome 2203 paper. The 'Kodak Color Print Copy attachment, Model 5S/5B-K' was available for use with Kodak 'digital' printers and Kodak S Series colour printers, such as Models 5S, 8S and 11S, for making colour copy prints from amateur's original prints onto 8.9cm wide Ektachrome paper. The print was loaded into a “print” carrier, which took the place of a negative carrier, a light was shone on the print, the shutter of the printer was opened and light was reflected off the print onto the Ektachrome paper. No negative or transparency was required to make copies or re-prints. The above reference to 'digital' printers should not be confused with the form of digital printing that became commonplace from the 1990s onwards. In the 1970s, 'digital' referred to the printers making use of in-built micro-processors, programmed (by Kodak) using a digital computer language. This gave the printers the facility to 'recognise' and adapt their exposure and colour filtration to suit a wider variety of 'non-standard' subjects. To read more detail of the Kodak MC Digital Printers, click the link here to download a pdf taken from a UK Kodak catalogue dated June 1980. By the mid-1980s, 2203 had been replaced by Ektachrome 21 and 22 papers (see below). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektachrome

14RC Paper, in the USA from 1972 At first the paper was processed in Kodak Ektaprint R chemicals but by 1974 the paper was being processed in a modified version of the Kodak Ektaprint R-5 process. The modified process was known collectively as Ektaprint R14. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||