| Kodak Colour Negative Film and Colour Print Making Materials & Processes - researched by Michael Talbert |

|

|

|

|

1880 - Eastman began commercial production

of dry plates in a rented loft of a building in Rochester, N.Y. 1889 - The first commercial transparent roll film, perfected by Eastman and his research chemist, was put on the market. 1891 - The company marketed its first daylight-loading camera, which meant that the photographer could now reload the camera without using a darkroom. 1892 - The company became Eastman Kodak Company of New York. 1898 - Kodak marketed the Folding Pocket KODAK Camera, now considered the ancestor of all modern roll- film cameras. It produced a 2¼ inch by 3¼ inch negative, which remained the standard size for decades. 1900 - The first of the famous BROWNIE Cameras was introduced. It sold for $1 and used film at 15 cents a roll. For the first time, the hobby of photography was within the financial reach of virtually everyone. 1908 - Kodak produced the world's first commercially practical safety film using cellulose acetate base instead of the highly flammable cellulose nitrate base. 1911 - The company's Blair Camera factory in Rochester was renamed the Hawk-Eye Works, and a department for the design of optics was established there in 1912. 1913 - The introduction of EASTMAN Portrait Film began a transition to the use of sheet film instead of glass plates for professional photographers. 1923 - Kodak made amateur motion pictures practical with the introduction of 16 mm reversal film on cellulose acetate (safety) base, the first 16 mm CINE-KODAK Motion Picture Camera, and the KODASCOPE Projector. The immediate popularity of 16 mm movies resulted in a network of Kodak processing laboratories throughout the world. 1928 - Motion pictures in colour became a reality for amateur cinematographers with the introduction of 16mm KODACOLOR Film. 1929 - The company introduced its first motion picture film designed especially for making the then, new, sound motion pictures. 1931 - KODAK VERICHROME Film was introduced offering greater latitude and finer grain than the KODAK NC (Non-Curling) Film which had been the standard since 1903. 1934 - Kodak A.G. (Germany) introduced the first of its 35 mm precision KODAK RETINA Cameras. 1935 - KODACHROME Film was introduced and became the first commercially successful amateur colour film initially in 16 mm for motion pictures. |

1936 - KODACHROME Film for 35 mm slides and 8 mm home movies. 1938 - The first camera with built-in photoelectric exposure control was developed; the Super KODAK Six-20. 1939 - Kodak added a READY-MOUNT service for 35 mm KODACHROME Film which made it possible to project slides as soon as they were received from a Kodak processing laboratory. 1942 - KODACOLOR Film for prints, the world's first true colour negative film, was announced. 1946 - Kodak marketed KODAK EKTACHROME Transparency Sheet Film, the company's first colour film which could be processed by the photographer with newly marketed chemical kits. Kodak employment worldwide passed the 60,000 mark. 1954 - KODAK TRI-X Film, a high-speed black-and-white film, was introduced. 1956 - KODAK VERICHROME Pan Film was introduced, a black-and-white film that replaced the popular KODAK VERICHROME Film launched in 1931. 1961-The company introduced the first in its very successful line of KODAK CAROUSEL Projectors, which featured a round tray holding 80 slides. KODACHROME II Film was introduced, providing a significant improvement over the long-established KODACHROME Film. 1963 - The line of KODAK INSTAMATIC Cameras was introduced, featuring easy-to-use cartridge-loading film, which eventually brought amateur photography to new heights of popularity - more than 50 million INSTAMATIC Cameras were produced by 1970. 1965 - Kodak developed the super 8 format and launched super 8 movies with new cartridge-loading KODACHROME II Film. 1972 - Kodak reduced the popular INSTAMATIC camera to pocket size with the introduction of five different KODAK Pocket INSTAMATIC Cameras, using a new KODAK 110 Film Cartridge - the line was so popular that more than 25 million cameras were produced in slightly under three years. 1980 - Kodak celebrated its 100th anniversary. 1981 -The introduction of KODAK EKTAFLEX PCT color printmaking products made it easy for home darkroom enthusiasts to make col or enlargements. 1982 - Kodak launched "disc photography" with a line of compact, "decision-free" cameras built around a rotating disc of film. KODACOLOR VR 100 Film was introduced, utilizing a newT-GRAIN emulsion technology. 1990 - Kodak announced the development of its Photo CD system and a proposed worldwide standard for defining colour in the digital environment of computers and computer peripherals. 1994 - At a January press conference, Kodak announced 30 new products, including KODAK ROYAL GOLD Film |

|

Some of the earliest colour

processes, as applied to motion picture film, can be read in

this Kodak publication for the British Kinematograph Sound &

Television Society entitled: 16mm home ciné colour film, named Kodacolor, appeared in 1928. Improved colour in the form of Kodachrome then arrived in the 16mm ciné format in 1935 and by 1936 Kodachrome was also available in 8mm ciné and 35mm still formats. The early 1928 Kodacolor was a lenticular additive colour film which employed the 'lenticular' process which made use of a black and white film stock, the base of which was embossed with a large number of minute lenses or cylindrical ribs, 22 elements per millimetre. When exposed through the base using a camera lens fitted with a banded three-colour filter, the image was recorded as a number of colour separation elements which, after a reversal processing, could be projected through a similar lens and filter to produce the original colours. The process, which had a number of disadvantages, was discontinued in 1935 with the introduction of Kodachrome. By the early 1930's, colour photography had reached well past the experimental stage. When “Agfacolor Neu” reversal film first made it’s appearance in 1936 it proved that a multi-layer colour film could be manufactured with the colour couplers incorporated into the three separate emulsion layers coated on the same support and processed in a single colour developer. A year previous to this, Eastman Kodak had marketed 16mm “Kodachrome” motion picture film but had chosen to process the film by a method of including the colour couplers for the three emulsion layers in three separate colour developers. Initially the processing procedure was extremely complicated. Not only were there three separate colour developers involved, but the film also had to be put through three separate “Dye Bleach “ baths, each penetrating the emulsion layers to a varying extent. Kodak

UK History; Kodachrome Availability and Processing Although requiring to be processed only by Kodak Ltd this did not mean sending film across the Atlantic to Eastman Kodak, Rochester, New York. Spurred on by World War II, with its danger to Atlantic shipping, it seems a processing service became available in the UK at the Kodak laboratories at Wealdstone, Harrow, Middlesex, around 1940. Ian on the Photrio blog site, suggests "...in a 1940 Kodak Ltd Catalogue, it stated that Kodak had suspended sending Kodachrome to Rochester for processing and were arranging for processing to be carried out in this country (the UK). The setting up of the UK Kodachrome processing plant was definitely due to the high number of merchant ships being lost". The Kodak factory at Harrow was established in 1891 on a seven-acre greenfield site, just to the west of the Harrow & Wealdstone railway line. It was a major employer in the area and by the 1950s the site covered 55 acres and employed around 6,000 people. But times change. Amateur Photographer magazine for w/e February 23rd 1985, in their 'NewsView', carried an article entitled 'Kodak property for sale' stating "The continuing decline in Kodak (UK) Ltd's Harrow operations now sees the company attempting to sell the 50-year-old Kodak Hall to the Borough of Harrow for £2m. Kodak Hall is (was) the recreational and leisure facility (1.4 acres) for employees working at Kodak's Harrow factory "The Hall isn't used to the extent it was by employees. Of course, when the Hall was built, Kodak had more employees at Harrow which was the site of Kodak's first UK Kodachrome processing laboratory". In 1957 laboratory staff moved to the site in Hemel Hempstead. Mr Shepherd (in February 1985) said management would make a decision soon about the fate of the Hemel laboratory site which will cease processing Kodachrome in April (1985), when UK processing will be taken over by Kodak Pathe in Sevran, France". James Casha, who joined Kodak Ltd in 1988, was given a final tour of the Harrow factory in October 2016. He reported "Today, despite an explosion in the number of images being taken, now with telephones rather than cameras, the demand for photographic paper has declined dramatically. The Harrow factory is now owned by Kodak Alaris (see below), who are reducing capacity to match this shrinking demand. Manufacturing will stop in October 2016. It is the end of an era for a factory that has been in operation since 1891 and was once the largest manufacturing facility in the British Empire!" By 2016 the Harrow factory had been reduced to just a producer of photographic printing paper. James comtinued "In years gone by, Kodak used to coat the paper base and add the iconic back-print at the Harrow site. Nowadays the paper base is brought in from Germany with the back-print and polythene coating already in place. All the factory has to do is to add the appropriate light sensitive emulsions!" Hemel Hempstead was locally known as 'Kodak Central' in the UK with (separately) a Kodachrome processing plant (Kodak Ltd; Box 14, Hernel Hempstead, Herts) and the main headquarters in the town centre, built in the 1960s. The processing plant clearly dates to, or before, 1957, when Kodachrome processing was moved there from Harrow. Kodak vacated their Hemel Hempstead town centre 'sky scraper' c75m tall office building in 2005, whereafter thebuilding was substantially modified and converted into apartments, completed in 2010. On september 5th 2023, Kodak Alaris announced that the previous day had been the official opening date of their new UK office, being the Kodak Alaris Global Headquarters also in Hemel Hempstead, UK. Processsing

early Kodachrome The first step was a black

and white developer, which produced a black and white negative

image in each layer. As this was not wanted, it was removed by

a bleaching bath. In 1938 the process was much simplified and the re-exposure step was made with red light fogging the bottom layer, which was then developed, then blue light for the top layer, which was then developed, and finally, the magenta layer was chemically fogged, and developed in the magenta developer. The selective exposures made sure that only one layer could be developed at a time. Although much simplified, the sequence was still too complicated to be carried out by a photographer using equipment in his own darkroom. Colour prints at that time were being made from transparencies by manual 'registration' methods such as "Tri-Chrome Carbro" and the "Kodak Wash-Off Relief", plus others. Mainly, these printing processes were only used by professional advertising photographers, since they were difficult to manipulate and involved much time and skill to get the best result, making the cost of even one print well beyond the pocket of the average amateur photographer. However, by 1941, Eastman Kodak had introduced a fairly quick and relatively cheap method of making prints from Kodachrome transparencies. Despite this facility, a colour transparency is not the ideal starting point for making a good colour print. The brightness range of the average Kodachrome could not be accommodated satisfactorily on the printing paper, resulting in white, burnt out, highlights and black shadows lacking in detail. Prints

from Kodachrome Transparencies, 1941-1961 ~ Minicolor and Kotavachrome By September 1941 the process had become reliable enough for Eastman Kodak to offer two types of colour print service:

The pages below are from a 'Minicolor Prints' leaflet dating from May 1942 advertising the three sizes of Minicolor prints available from 35mm transparencies. A full copy can be downloaded as a pdf by clicking here or on the image below. |

|

2. 'Kotavachrome' prints were made from Kodachrome Professional sheet film transparencies. A contrast reducing mask was first made from each transparency on 'Kodak Masking Panchromatic film' and' if the exposing light was filtered while exposing the mask, certain colours could be made to appear brighter in the print (see below). |

|

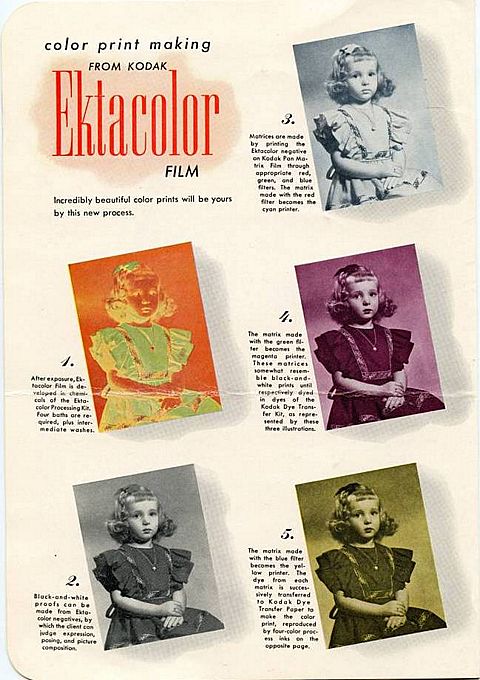

Professional colour prints from sheet film transparencies could be made by the then new Kodak 'Dye Transfer' process, which had superseded the Eastman Kodak 'Wash-Off Relief' process in 1945. In 1945, 'Minicolor' prints were renamed 'Kodachrome' prints. The leaflet below is dated October 1946 when prints could be ordered in four sizes, (2x, 3x, 5x and 8x) plus two 'Special size' prints of 8 x 10 inches and 11 x 14 inches. A complete pdf of this leaflet can be downloaded here or by clicking on the image below. Kotavachrome prints were now termed as 'Kodachrome Professional' prints. These were supplied in any size up to a maximum of 11 x 14 inches, based on the standard sizes of 8 x 10 inches and 11 x 14 inches and could be cropped if desired. It is not known if the making of contrast reducing masks were included in the service. The author thinks this was unlikely and Eastman Kodak, by this stage, may have been producing a printing material not unlike a duplicating film, where the emulsions were of especially low contrast (see: Ektachrome Duplicating films). |

|

|

Larger sizes of print were made from Kodachrome Professional sheet films by the Kodak Dye Transfer process now also including (1946) Ektachrome sheet film transparencies. Prints made by the Kodak Dye Transfer process would have been of far superior quality compared to prints made by any reversal colour print process. Below is shown a leaflet advertising Kodachrome films and prints plus other services available in April 1946. By that date the chemicals, Matrix film, and paper were obtainable for the advanced amateur photographer to make their own colour prints from transparencies using the Kodak Dye Transfer process, as is mentioned on the last page of the leaflet. A complete pdf of this leaflet can be downloaded here or by clicking on the image below. |

|

|

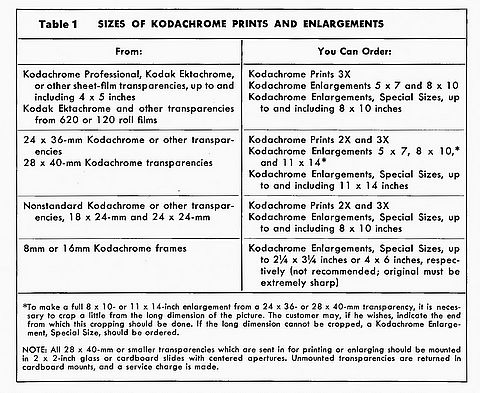

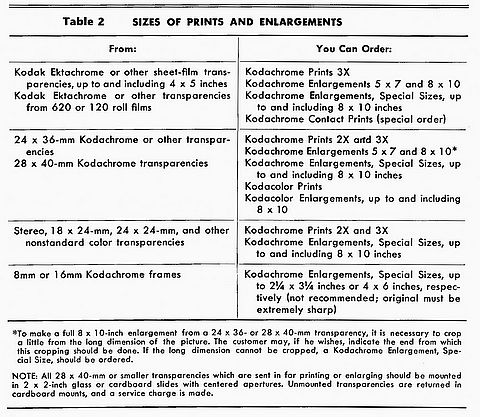

By July 1950 Kodachrome prints and enlargements were obtainable from all sizes of transparencies up to and including 4 x 5 inches. Table 1, below, shows the film types and sizes of prints and enlargements available. By 1951 Eastman Kodak were offering a service to provide 'Kodacolor' prints from 35mm transparencies. An internegative was made by printing the colour transparency onto a colour negative film, possibly by tungsten light onto Kodacolor Type A film. It is not known for certain how these internegatives were made or if there was any contrast reducing procedure. Kodacolor Type A negative film was introduced in 1949. Although daylight type Kodacolor had been available since 1942, the artificial light balanced film would have been more suitable for exposing internegatives by tungsten light. Also in 1951 Eastman Kodak withdrew Kodachrome Professional sheet film from the market and Ektachrome became the only colour reversal sheet film supplied by Eastman Kodak. Table 2, below, shows the additional printing service for Kodacolor prints made from colour transparencies in November 1951. In 1955 Eastman Kodak introduced 'Kodak Color Print Material, Type R' for making colour reversal prints from transparencies. In the USA only this was sold in rolls and sheets to professional photographers to make prints from their transparencies without having to go to the trouble and expense of making Dye Transfer prints. This material was renamed 'Kodak Ektachrome Paper' in 1958. Kodachrome prints and enlargements were still available in 1961 but it is thought by this date the prints were being made onto Kodak Ektachrome paper. Also in 1961, Eastman Kodak introduced a colour internegative film in 35mm format, and this film may have replaced Kodacolor Type A film, or Kodacolor Universal film from 1955, as a material for internegatives. The prints made from Kodacolor film internegatives, or 'Kodak Inter Negative Colour Film', were made on Kodacolor paper, Kodak Color Print Material Type C or Kodak Ektacolor paper. Table 3, below, shows sizes of Kodak Color Prints and Enlargements from transparencies for December 1961. (References: Kodachrome Professional films 1942. Kodak Reference Handbook 1943. Kodachrome and Kodacolor Films 1946 & 1948. Ektachrome, Kodachrome Professional films 1948. Kodachrome Films for Miniature and Movie cameras 1952 & 1953. Kodak Color Films 1950, 1951, 1957, 1959 & 1961. 'Colour Photography, the first hundred years' Brian Coe, 1979). |

|

|

|

|

|

|

Contrast

Masks made from Kodachrome Sheet Film Transparencies for Kotavachrome

Prints Each mask was made on “Kodak Masking Panchromatic Film”. Masking Panchromatic was a black and white sheet film which had a thin removable light sensitive layer attached to the film base. In total darkness, or under very dim dark green safelighting, this layer was carefully removed from it’s base and cemented onto the emulsion side of the Kodachrome sheet film transparency to be printed. The base side of the masking film’s removable layer was in contact with the emulsion side of the transparency. The Kodachrome was then exposed through the base, the emulsion side facing away from the light source, thus printing the highlights onto the layer of the masking film. Most masks were exposed with a red filter in front of the light source which improved the colour rendering of the greens and cyans in the Kotavachrome print. The exposed mask was processed to a negative while still attached to the transparency, the layer of film protecting the emulsion side of the Kodachrome from any harmful black and white processing chemicals. The mask layer was attached to the Kodachrome with its emulsion side outwards, so as to allow the black and white developing chemicals to act on the b&w layer. When processed and dried, the combination was used to expose the Kotavachrome print material, again exposing with the base of the Kodachrome facing the light source. After the print was processed, the mask layer of film was peeled off the transparency. Unlike other methods of masking, which required a separate piece of film to be registered with the transparency, there were no registration problems using this method as the mask, once exposed, never left the transparency until after the final print was made. (For a more complete explanation on masking using a separate film and for colour correction see “Duplicating Transparencies”) Although “Minicolor” prints were made from amateur photographer’s 35 mm transparencies, Eastman Kodak also made Kotavachrome prints from 35mm Kodachromes. The 35mm size was masked in the same way but the protective layer of varnish on 35 mm films had to be removed before the masking layer could be attached. Kodak Masking Panchromatic

Film was available in various sizes, viz: Although Kotavachrome prints could only be made by Eastman Kodak, the Masking Panchromatic film was also used by Colour Laboratories and Professional Photographers making colour prints from transparencies by the “Kodak Wash Off Relief “ Process, which became known as the “Dye Transfer” process after 1945 in the U.S.A. Kodacolor

Aero Reversible Film Like Agfa’s Agfacolor Neu film of 1936, any colour material, film or paper, having the colour couplers combined with the three emulsion layers at the time of manufacture, could be processed in a much simpler, and much faster, manner than that of Kodachrome. Only one colour developer and one bleach bath were required. The first film manufactured by Eastman Kodak containing “Protected Couplers” was Kodacolor Aero Reversible Film in 1940. Mainly used by the United States Army Air Force for reconnaissance purposes, the special feature of this film was that it could be processed anywhere without elaborate equipment. Kits of chemicals for making up the five processing baths were available. Processing was much like E1 but with longer times, very likely processing at 68°F (20°C). The time taken to process the film, not including drying, was around 90 minutes. Despite the name “Kodacolor”, the film produced a transparency after processing, and bore no relationship, apart from the colour couplers, to the eventual Kodacolor negative film.The processing sequence and chemical baths for Kodacolor Aero Reversible film were not unlike the processing procedure and baths for the earliest type of Kodak Ektachrome sheet films (see here). It was probably about 6 to 10 ASA and had a high contrast. Two sets of filters were supplied with the film, one filter to correct for the various emulsion differences, and to balance it for average daylight. The other filter, or filters, were to correct for “haze”, or blueishness in distant subjects. The “Haze” filters were likely to have been 'Wratten Filter No.1' and 'Wratten Filter No.2A', 2A being slightly stronger. It was replaced, or renamed, ”Ektachrome Aero film – High contrast”, possibly in 1946. |

|

|

||

|

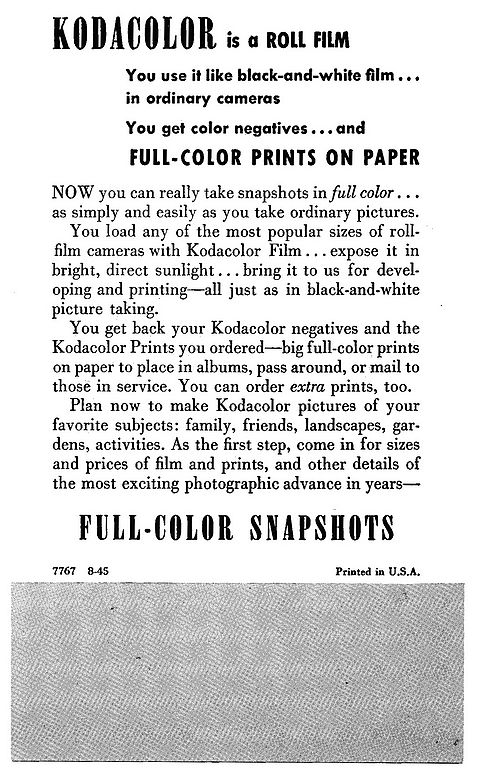

Introduction In November 1941, the Director of Research at the Eastman Kodak Company, Dr. Kenneth Mees, outlined an entirely new system for making colour prints from a colour negative film - called Kodacolor. The announcement was entitled "Direct Processes for Making Photographic Prints in Color, communication No.832, from Kodak Research Laboratories.” Like Kodachrome, this film was coated with three light sensitive layers, sensitive to red, green, and blue light. Each layer incorporated colour couplers, like Kodacolor Aero film, and after exposure the film could be developed in a single colour developer, producing a colour image in each layer. After bleaching and fixing, an image of pure dyes was formed of the original subject. However, this was where the similarity between previous colour films ended. Unlike Kodachrome, or Kodacolor Aero film, this was a negative image, colours were reversed as well as density. Areas of blue sky reproduced as dark yellow, grass became pink, and reds became blue-green. The photographic colour printing terms of "pink" and "blue-green" are the subtractive colours magenta and cyan. All processing of Kodacolor films was undertaken by Eastman Kodak at Rochester N.Y. The photographer handed in his exposed films to a Kodak dealer who sent the films to Eastman Kodak at Rochester. The cost of processing the film was included in the film price at the time of purchase but did not include the cost of any prints. To allow the film to be used in fairly basic, non adjustable cameras, the film speed of Kodacolor was at least twice that of Kodachrome. A Weston rating of 20 (25 ASA or ISO) was quoted in the data sheets. This was adequate for an exposure of 1/50th of a second at f11 for an average subject in bright sunlight. Initially, the film was balanced for daylight and blue flashbulb exposures. The data sheets gave specific instructions for "fill-in" flash exposures using Nos. 21B and 5B photoflash lamps. The film speed was increased by one third of an f-stop in 1955, to Weston 25, or 32ASA/ISO. Although the Kodak Data book - "Kodachrome and Kodacolor Films" mentions that Kodacolor film had a limited exposure latitude compared with black and white films, it also pointed out "Satisfactory Kodacolor prints can be made from Kodacolor negatives which received as much as two full f-stops more than the correct exposure". However, overexposed negatives generally gave a lack of detail in the highlights of the print, while under exposure caused black shadows and low contrast prints. Photographers were also warned that Kodacolor pictures made on dull, overcast, cloudy days tended to turn out flat (lacking in contrast) and with a blueish colour cast. Good black and white prints could be made from Kodacolor negatives, and so a colour negative which had been incorrectly exposed, or lacked colour accuracy due to being exposed under mixed lighting conditions, could often be used to at least produce a satisfactory black and white print. Eastman Kodak described "Kodacolor" as a "colour medium for snapshotters", who prefered a colour print as their end result, as opposed to a Kodachrome transparency. Kodacolor gave pleasing, attractive colour prints but the process could not give exact colour fidelity. Reds and blues were reproduced well, yellows were rather dull, while greens tended to be tinged with blue. The structure of the film was similar to the early Agfacolor negative film, consisting of three colour sensitive layers. The Red sensitive layer, producing the cyan dye image, was coated on the base of the film. On top of the red sensitive layer was coated the green sensitive, producing a magenta dye image, then a yellow filter layer, and on top, a blue sensitive layer, giving a yellow dye image. The film was principally intended for amateur photographers, with simple, basic roll film cameras. In 1942, when Kodacolor first appeared (in the US) roll films were available in six different sizes:- 127, 120, 620, 116, 616, and 122. 35mm Kodacolor film was not manufactured because this film size was well catered for by Kodachrome and, at that time, the enlarging of a small 35mm image would have shown the granular structure of the early Kodacolor film in print areas of medium density, such as a cloudless sky. At that time, all processing and printing of Kodacolor film was carried out by Eastman Kodak at their laboratories at Rochester, N.Y. The photographer handed in his exposed rolls of film to a Kodak photographic dealer who then sent the films to Rochester for either, “developing only” or “develop and print”. The purchase price of the film included “developing only”. In the first instance the photographer was able to see the negatives before ordering prints. Then he selected the best exposed negatives and marked the order e.g.“one off or two off” as the case might be. In “Develop and Print” there was no way the photographer could see the negatives before they were printed, and he had to take a chance on whether his exposures were correct. Eastman Kodak printed one print off each of the negatives according to the negative quality within certain limits. Some negatives may have been judged by the printer as too bad to print (gross underexposure, fogged), and if these particular negatives were important to the photographer for personal reasons, those negatives had to be returned by the owner marked “Print regardless”. All prints, irrespective of negative size, were made 2&7/8ins wide plus white borders of about ¼ins all round. The length depended upon the length of the negative. The smallest prints were from square negative, and the largest from size 122 rollfilm, which, in some cameras, produced a massive 3¼ x 5½ ins negative. The print size from these negatives was 2&7/8ins x 5&1/8ins, a little smaller than the negative! However, 122 rollfilm was short lived, by 1948 this size was no longer manufactured in Kodacolor. KODACOLOR

Film from 1942 to 1955 Kodacolor

Film in 1942 |

||

|

|

|

| As far as is known, the following images are of a very early “Kodacolor” print return wallet which was used to contain Kodacolor negatives and Kodacolor prints when the film was processed and printed by Eastman Kodak company at Rochester, New York, or an Eastman Kodak subsidiary laboratory. There is no date printed on the wallet, but indications from the contained (unmasked) negatives suggests that the wallet dates from the around the mid-1940s. The section entitled “Like your prints?” (on the wallet; see right hand side image) is reproduced almost word for word on a page in an Eastman Kodak Data booklet “Kodachrome and Kodacolor Films”, Fourth edition, March 1948. The negatives are unmasked, so must pre-date 1948. | ||

.jpg) |

.jpg) |

|

.jpg) |

||

|

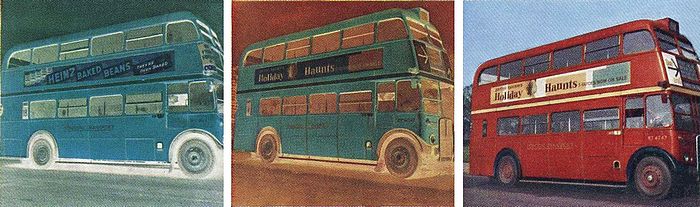

Because of the age of the film, the Kodacolor negatives in the above envelope were incapable (by 2023) of producing acceptable colour prints. Below left shows one such negative. The (typical) best achievable is as shown centre, below. A better, though not necessarily accurate, coloured image was obtained by converting the central image to monochrome and then 'colourizing' it, using the AI website https://palette.fm/. The result is shown right, below. |

||

.jpg) .jpg) .jpg) |

||

|

Kodacolor

Film in 1944 To alleviate this problem, from 1944 an extra emulsion layer was included, between the yellow filter layer and the green sensitive, magenta dye forming layer. This layer acted as a “positive mask.” It’s function was to decrease the contrast of the colour negative as a whole but without any loss of colour saturation. The actual layer itself was a black and white emulsion, sensitive only to blue light. It was too slow to be affected by the camera exposure, it’s speed being much the same as a Process film or Line film emulsion. Process film was a slow speed, high contrast, blue sensitive film, used for copying black and white line originals, and for making positive transparencies from soft black and white negatives. It was faster and less contrasty than Line Film. Line film was a very slow speed, very high contrast blue sensitive film for making line negatives from architects and engineers plans and drawings. Both films had various uses in photolithography. As a result of the positive mask layer, the colour negatives appeared rather “heavy” regardless of exposure and required a longer printing exposure. It is believed that processing of the film took slightly longer because the mask layer had to be developed separately to the three colour sensitive layers. After processing the mask held back some of the light projected through the shadow areas of the negative. Since the mask added density to the shadow areas, less light could reach the printing paper from the shadow area, so the printing exposure could be increased to put more detail into the highlights of the print, thus lowering the overall contrast. The mask only added density to the shadow areas of the negative. Kodacolor film with the black and white mask was marketed from 1944 to 1949. |

||

| 1945 and 1946 Kodacolor Leaflets | ||

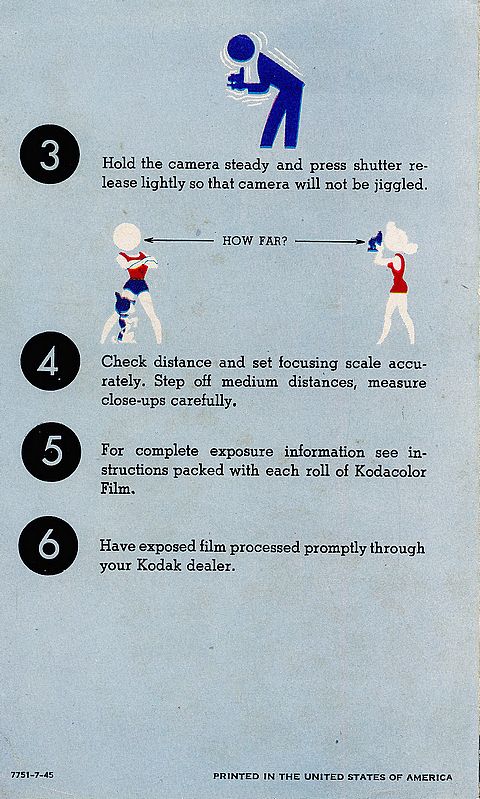

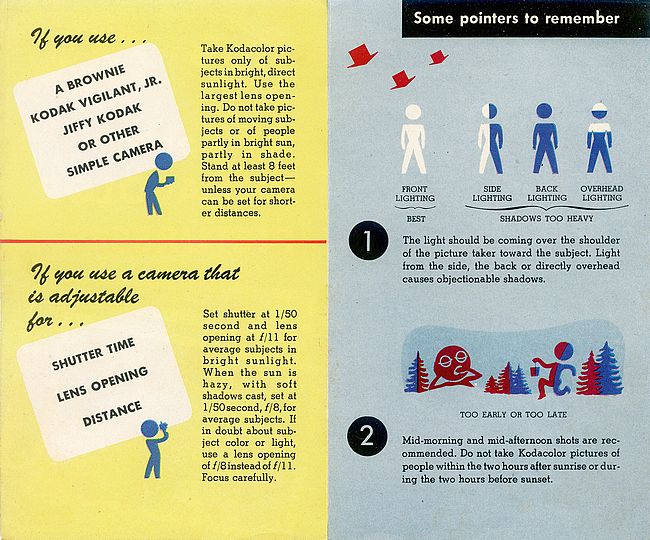

| This leaflet, 'Tips for better Kodacolor Pictures', dated July 1945, gives many valuable hints and directions on how to obtain the best possible prints from your Kodacolor films. On adjustable cameras, 1/50 second at F/11 was the recommended exposure for snapshots in bright sunlight (suggesting a film speed around 25ASA/ISO). The pictures below are front and rear, followed by the reverse double page. | ||

|

|

|

|

||

|

|

|

| Below is a larger 'hand-out' leaflet dated March 1946 | ||

|

|

|

|

|

|

|

Kodacolor

Film in 1949

~ Colour Masked Kodacolor

Film. Due to the dye deficiencies, the magenta dye absorbed some blue light, which it should have passed freely, and the cyan dye absorbed a portion of light of it’s own colour. Prints made from Kodacolor negatives showed greens tending towards blue and weak reds. In the first case the blue light which was being absorbed by the magenta dye should have been used to make the green yellower. In the second case the portion of cyan dye that was being absorbed by it’s own layer should have been used to make the print redder. More blue light makes the print yellower, and more cyan light makes the print redder. If the green in the print was too blue and a blue filter was inserted in the printer to correct this, it is likely the whole print would turn out too yellow, as the other colours in the print would have been correct, or nearly so. A solution to this problem of dye deficiencies was first thought of by W.T.Hanson of Eastman Kodak in 1943. His proposal was to create a “mask” in the film by making use of “coloured couplers” to correct for the overlapping absorptions of the cyan and magenta dyes. |

||

|

The coloured mask was actually a positive image, exactly registered with a defective negative dye image. The coloured mask corrected the dye deficiencies in the negative image to the extent of the overlapping absorptions. The negatives took on an orange–red colour. Kodacolor film with “integral coloured masking” as it was called, was produced from 1949, and in the same year an artificial light version of the film was launched (see left). It was balanced for Type A photoflood lamps (approximately 3400°K). It’s speed to photoflood lighting was 20ASA and it could be exposed to daylight with a Kodachrome Type A filter, No. 85 at 12ASA. Paul Godfrey has supplied me with two pdf files which contain details of Kodak's colour printing services available in the USA during 1952 and 1953. |

|

_cr.jpg) |

The document alongside is part of the leaflet (dated Julty 1949) included with the Kodacolor Type A film shown above. It deals with the subject of getting the film processed and the option to also have prints made. The full leaflet can be downloaded as a pdf here. The resolution is low but readable. There was no mailing envelope included with the film. The roll of film came in a metal (possibly aluminium) container. After the film had been used, the customer would take the film, preferably in its container, to a local Kodak dealer who then sent the film to Kodak at Rochester, New York, for processing. Customers had the choice to just receive our negatives back (at no further charge) or arrange with the dealer to have prints made, for which the customer would have been charged accordingly. The possibility to just have negatives returned (no prints) was because of the cost of colour printing. The customer had opportunity to assess their negatives and decide which were worth having printed. This would have entailed taking the relevant negatives back to the Kodak dealer and waiting for the prints (and the original negatives) to be returned from Rochester. The leaflet below is taken from “Let’s take Kodacolor Pictures”, an Eastman Kodak Company publication No. E-10 printed in March 1955. It tells about the processing and printing of Kodacolor negatives. The negative process would have been the later B-41, almost identical to C-22. |

|

|

||

|

THE TRUTH

UNMASKED? The far left illustration shows an Agfacolor negative (edit: probably CN17) which does not have a mask incorporated. The second picture is of a Kodacolor negative which is integrally masked; while the furthest right shows a print which might have been made from either, though in fact it is from the Kodacolor one. |

||

|

What is the advantage of masking? The answer is that the makers using this system aim to improve the accuracy of colour rendering in the final print; and to a large extent they succeed, especially with greens, which have always been difficult in colour photography. In Kodacolor and Ektacolor two masking layers are employed; a pink one to offset failings in the cyan dye, and a yellow one to adjust for the short-comings of the magenta. The combination of the two gives rise to the orange appearance of negatives made by Kodak. Ilford incorporate only a yellow mask for the magenta layer in llfocolor, and hence the rather yellow appearance of colour negatives made with this film. The mask is produced by colouring the actual colour couplers concerned; thus the cyan couplers are themselves pink. However, where they are used to produce a dye image their own colouring is destroyed, and with it the masking effect at that particular point. |

||

|

|

||

| Kodacolor Film in 1956 |

|

|

|

It is thought that the new Kodacolor Universal film, and its new Process C-22 developing sequence and chemicals, was introduced in the USA in February 1956. The Universal Kodacolor was balanced for the light of Clear Flashbulbs (3800°K), and was one third of a stop faster than the older Kodacolor at 32 ASA (ISO). The colour of the mask was

slightly different to the older Kodacolor which produced a yellow

brown mask. The mask colour of the new Kodacolor was a reddish

brown. Alongside is ahown the cover of a Kodacolor Booklet of 32 pages, published by Eastman Kodak Company, publication No. E 10, in March 1955. Intended primarily for the amateur photographer, it contains information on “Outdoor Pictures”, “Flash Pictures”, “Exposure Tables”, “Flood Lamp Pictures” and “Ordering Prints and Enlargements”. There are several exposure tables, for Daylight and Type A films. Illustrated with some very well reproduced square colour pictures, as the film was only available in roll film sizes in 1955. Inside the front cover there is stuck an information sheet advising of changes to Kodacolor film. It states that a new film, Kodacolor Universal Type, is now available, replacing the Daylight type, and the Type A films. The sheet gives new flash distances for some Kodak cameras and a table of new Flash Guide Numbers. Kodacolor Universal Type film was sold at a price that did not include the cost of developing to a negative, unlike the previous Kodacolor films. |

||

|

Kodacolor Roll Film comes to the UK, October

1957, though

not widely available to the general public until Spring 1958 The trouble with unwanted absorption by these cyan, magenta and yellow dyes has been overcome to a large extent by Kodak in Ektacolor and Kodacolor (the former being a professional film) and in the cine film known as Eastmancolor, by using an integral masking system. A similar system has been adopted by Imperial Chemical Industries in the new ICIcolor. The colour-forming chemicals incorporated in colour negative processes are themselves normally colourless before development and only become coloured during processing, when the particular dye, be it cyan, magenta or yellow, is produced in the particular layer in proportion to the blackening of the silver. That is to say, if in the negative light has not acted at all on the emulsion there will be no blackening of silver and no conversion of the colour-forming material into the particular dye. On the other hand, if the emulsion has been fully exposed to light the maximum amount of dye is produced together with the maximum blackening of the silver. In the subsequent bleaching process the blackened silver is removed leaving only the dye image. Now if we consider the cyan layer as fully exposed to light, then after the bleaching and fixing we get a layer of cyan dye, the function of which is to absorb red. Now, as we have indicated above, this cyan dye also absorbs some blue, thereby usurping to some extent the function of the yellow layer. Let us imagine this cyan layer had 20 per cent unwanted absorption of blue. The method adopted in integral masking is to make this colour-forming material yellow in its normal state instead of colourless. Then, if no light action has occurred in the emulsion, after bleaching and fixing we shall have a plain yellow dye absorbing say 20 per cent of the blue. If on the other hand the silver has been fully affected by exposure and fully blackened, then after bleaching and fixing we shall have a cyan dye also absorbing 20 per cent of the blue. In other words, no matter what amount of blackening or what variations of exposure are given to the particular layer, it will have a uniform absorption of 20 per cent of the blue, irrespective of gradation. We are not giving actual figures but merely giving a theoretical example. In a similar way the magenta layer, whose function is to absorb green, but which may absorb say 15 per cent of the blue, is also made coloured, the particular yellow or orange coloration being so arranged as to absorb the same percentage of blue as the magenta does when fully developed. The yellow layer, which produces very efficient dye, is not treated in any way, but the two colourings in the magenta and the cyan layer can be made to compensate to a very large extent for the faults in these dyes. An integrally masked negative, such as Ektacolor, Kodacolor, ICIcolour or Eastmancolor when held up to the light appears strongly orange owing to this additional blue and green absorption, but when placed in the enlarger and projection printed on to similar tripack paper (which does not contain any masking dyes) the final result is very similar to that which will be produced with a theoretically perfect cyan and magenta dye. The fact that the negative looks a very peculiar deep orange is very puzzling to the uninitiated, but it must be remembered that the appearance of the negative is not important so long as the final result is what we require. Our own tests, using the British-made

material, showed that the prints now being produced are very

good indeed. Their prices are as follows: Amateur Photographer magazine reported, in its 'News and Reviews' section, 23rd October 1957 edition, "Limited supplies of Kodacolor rollfilm in 120 and 620 sizes are now available. It is a colour negative material for producing colour prints on paper, and can be used in daylight, flash or srtificial light without compensating filters. It is rated at 32 ASA (26° BS) in daylight. 3½ x 5ins or 3½ x 3½ins square prints are supplied on semi-glossy paper and processing is handled only through Kodak dealers. Kodacolor film is 12s.8d excluding processing and prints; processing to colour negatives 6s.6d per film and prints are 2s.9d each. We shall publish fuller details on this film in the near future." In July 1958, MCM reported

in its "New York Letter": |

||

|

KODACOLOR

X Films Kodacolor X remained on the

market until 1975, but thereafter the C-22 Kodacolor & Kodacolor

X films were gone forever. However, the C-22 process lived on

for another four years. The C-22 process was last mentioned in the British Journal of Photography Annual (BJPA) 1985 edition, with formulae and processing steps. |

||

| Below are shown

boxes of Kodacolor, Kodacolor X and Ektacolor Professional Type

S films. All 120 size. Kodacolor: Expiry date August 1961. Kodacolor X: Expiry date December 1968. Ektacolor Professional, Type S: Expiry date May 1976. |

||

|

||

|

|

|

| Process C-22 with High Speed Ektachrome Below are shown examples of the use of Process C-22 Chemistry with High Speed Ektachrome, a colour slide film intended for processing to positive transparencies in Process E2. |

||

.jpg) |

.jpg) |

Two colour negatives taken in 1971 on Kodak High Speed Ektachrome 120 roll film exposed at 250 ASA (ISO) and then processed as negatives. The film was processed in Kodacolor C-22 chemicals at 75°F using a colour development time of 7 minutes. The remainder of the process was exactly the same procedure as when processing Ektacolor or Kodacolor negative films. The result is an unmasked colour negative with a pronounced magenta cast. The purpose of using High Speed Ektachrome film as a negative material was to make use of a speed increase as the film could be rated at 250 ASA (ISO). High Speed Ektachrome film processed normally as a transparency in E2 or E4 chemicals was rated at 160 ASA (ISO). The fastest colour negative film obtainable in 1971 was Kodak Ektacolor Professional film Type S rated at 100 ASA (ISO). As well as a gain of about 1½ stops in speed there was also a gain in contrast as shown in these pictures taken in sunlight. There is also a slight colour “cross over” of red shadows and if the pictures were darker, cyan highlights would appear. This “cross over” would show more in a less contrasty subject. It would have been better to use this technique in very dull, flat lighting than sunlight. The colour “cross over” shows most in the “old barn” picture as red shadows with no detail, and the highlights, (the geese), are “burnt out”. The negatives shown here were scanned and the positive prints were made digitally but only the colour balance of the prints was corrected, the contrast was not altered. This is to show how the prints may have looked in 1971. When making the prints in 1971 from the unmasked negatives, a blank piece of Kodacolor film, i.e. an “orange” mask, was included with the printing filters to make the negatives more like masked colour negatives. The original 1971 prints were made on Kodak Ektacolor Commercial paper and the strong magenta cast, otherwise resulting in very green prints, was filtered to neutral using Yellow and Cyan printing filters.

|

.jpg) |

.jpg) |

|

|

||

|

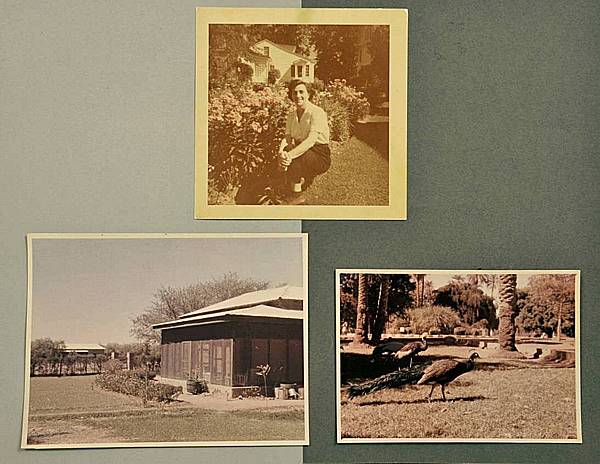

Michael Talbert comments on

how the following images were produced: Possibly the very strong orange mask in the C-22 negatives helped protect the dyes from fading, whereas the C-41 Kodacolor II negatives have a much “thinner” colour mask. It’s rather odd that the Kodacolor II film's 120 negatives have faded, but the Vericolor II 120 film negatives haven't, as the first two pictures show. The fading of Kodacolor II negatives is not unique as I have another 120 Kodacolor film, taken late 1976, and that has faded as well. |

||

|

|

|

| Vericolor II Professional film, Type S negative, Process C-41, taken February 1976 on 120 film, 2¼ inch square negative. | Kodacolor II negative, Process C-41, taken February 1976, on 120 film, 2¼ inch square negative. This negative has faded to blue, although stored in the same place as the Vericolor II Professional negative (seeleft) Print shows excess yellow-green, due to blue-magenta cast on the negative. | Ektacolor Professional Type S negative, Process C-22, taken October 1975 on 120 film, 2¼ inch square negative. Note the mask is much more orange, and denser, than the Process C-41 negatives. |

|

|

|

|

|

|

| Ektacolor Professional Type S negative, Process C-22, taken November 1975 by electronic flash on 120 film, 2¼ inch square negative. | Kodacolor X negative, Process C-22, taken June 1973 on 120 film, 2¼ inch square negative. | |

|

|

|

|

|

The negatives and 'prints', to the left and below, are from two different Agfacolor films, but reproduced here for ease of comparison. |

| Agfacolor CNS negative, taken February 1976. The negative has faded slightly, but the print shows only a feint blue cast due to the fading. 120 film, 2¼ inch square negative. Agfacolor four-bath negative process. | Agfacolor 80S negative, taken February 1976. The negative has faded, and the print shows blue shadows and yellow highlights. 120 film, 2¼ inch square negative. Agfacolor four-bath negative process. Agfacolor 80S film was the professional version of Agfacolor CNS 2 film. | |

|

|

|

|

Development Inhibitor Release Colour Couplers

(DIR couplers) Although DIR couplers were first incorporated into Kodacolor II films in 1972, Vericolor Professional films also used the same type of colour couplers. In 1972 the 16mm film size became the new 110 film, and Kodacolor II film was the first colour negative film to be produced in this size. It was also the first film to be designed to be processed in the new “Flexicolor” chemicals, which collectively became known as Process C-41. The film was sold in “Easy Load” cartridges, for “dropping into” the camera, much in the same way as a 126 cartridge, and the cameras were known as “Pocket Instamatics”. In 1972, Eastman Kodak in the USA introduced three new cameras for taking pictures on the new 110 format film. The cameras were sold in simple “Outfits”, or the cameras could be purchased separately. The outfits consisted of the camera, a flash cube, (Magicube of four flashes), a Kodacolor II film of 12 exposures, and an instruction book. Kodak Pocket Instamatic 40

camera outfit. Ten basic features of these cameras were listed in their USA 1972 Kodak Professional Products catalogue.

In 1975, Eastman Kodak Color Processing Services in the USA were offering to make “3R” colour prints (R = rectangular), from 110 negatives and transparencies in 3½ x 4½ inches, and colour enlargements in 5 x 7 inches. It is very likely that coloured grain would have begun to show in the 5 x 7 inch size enlargements. |

||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

There is little known of the methods and processing procedures Eastman Kodak used at Rochester to process the earliest versions of Kodacolor film. As early Kodacolor film was available only in roll film sizes, it is likely that “dip and dunk” film processing machines were used to develop the films to colour negatives. Modified black and white film processing machines may have been employed, more tanks being added for extra chemical solutions and washes. 1942

to 1944 ~ Kodacolor Processing procedure

The temperature of the baths

is likely to have been around 68°F. 1944

to 1949 ~ Kodacolor Processing (the second type of Kodacolor film) The film had a black and white contrast “mask” layer between the yellow filter later and the green sensitive layer. The mask layer was a very slow speed, blue sensitive emulsion, too slow to be affected by any camera exposure. The film was processed to form a dye negative image in each of the three colour coupling layers. The film was then exposed to blue light through the base, printing the already developed cyan dye and magenta dye layers onto the mask layer. The exposure did not affect the blue sensitive top layer because the yellow filter , underneath the blue sensitive layer would “stop” any blue light. The mask layer was then processed in a soft working black and white developer to form a weak positive mask image of the shadow areas of the green sensitive layer and red sensitive layer. The exposure of this layer took place after the film had passed through the Bleach bath. The idea was, when the negative was printed onto Kodacolor paper, obviously through the base of he film,the mask would have held back some of the exposing light from the shadow areas of the negative, thus lowering the contrast. The processing sequence may have been something like the one used for the original Kodacolor film outlined above but with additional steps.

Possible Processing Sequence:

KODACOLOR

Film Processing, 1949 – 1956 ~ (the third type of Kodacolor Film) Process

C-22 KODACOLOR Film Processing; post-1956 ~ (“Universal” type of Kodacolor

Film - see above)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The above C-22 process, dating from 1955–56, shows two processing times:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In 1963, Ektacolor Professional Type S roll film was introduced, the same emulsion as the sheet film on a roll film base. At first available in 120 and 620 rolls, it was joined by a 35mm size in 36 exposure cassettes and long lengths of bulk film a few years later. About this time, the development time for all C-22 Kodacolor films was increased to 14 minutes, and the agitation rate was decreased to an initial 15 second agitation for the first minute and thereafter once per minute. It was then possible to process Kodacolor, Kodacolor X and Ektacolor Professional Type S roll and 35mm films in the same processing run. The time for the various sheet films remained the same as previous i.e. 14 minutes. By 1965, early Kodacolor film was almost obsolete, having been replaced by the then new faster Kodacolor X. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Unit 1 contains the Developer and Stop Bath. Unit 2 contains the Hardener, Bleach and Fixer. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Notes.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Processing

C-22 Film in C-41 Chemistry The more modern, but high temperature (100°F), C-41 chemistry (see below) is incompatible with C-22 films, where the highest process temperature was 75°F. The higher C-41 temperature would damage the C-22 film emulsion. It might even strip it off its celluloid backing ! But it might be possisble to use a modified C-41 procedure. The C-41 Bleach and Fixer will work at 75°F as this was the lowest temperature for processing C-41 films; 6½ minutes in each. You could get away without using the Stabilizer. The Wash times might have to be increased by 50%. The C-41 Development time is 3¼ minutes at 100°F. Working on the old black and white developer rule, where development time has to be doubled for each 10 degrees Fahrenheit reduction in temperature, would suggest 6½ minutes at 90°F, 13 minutes at 80°F, so about 19 minutes at 75°F. Hence, it might be possible to colour develop a C-22 film in C-41 chemistry, all at 75°F.

Notes:

ALTERNATIVELY,

try Black & White Processing Chemistry The above site's owner puts colour films through Kodak HC 110 developer which is a bit like a liquid D-76, though maybe a bit more energetic than D-76. This route is almost certainly better than trying to develop out-dated colour negative film in hopes of achieving colour results, especially if the original colour chemistry is no longer available. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

KODACOLOR

II Film and the FLEXICOLOR Process C-41 The film was initially intended to fit the new amateur “Kodak Pocket Instamatic “ cameras taking 110 size film, a new format giving a negative size of only 13mmx17mm. The grain structure of the existing Kodacolor X and Ektacolor Professional colour negative films were not fine enough for use in the new ultra small 110 cameras. Following the idea of the original (1962) Instamatic cartridge Type 126 film, 110 films were sold in cartridges for slotting into the Kodak Pocket Instamatic cameras. The ultra small negatives were sharp enough to make enlargements up to 3½x4½inches. Prints much larger than this size showed objectional graininess. The film was coded as:-

Kodacolor II could be given the same exposure times as Kodacolor X film. The daylight speed was 80 ASA (ISO), exposed without a filter. Photoflood speed was 25 ASA (ISO) with a Kodak No.80B filter. Tungsten speed (3200) was 20 ASA (ISO) with a Kodak 80A filter. The negatives were suitable for printing onto Kodak Ektacolor 37RC paper. Kodacolor II film was designed for processing in the new FLEXICOLOR chemistry, also known as “Process C-41”. Flexicolor chemicals were principally intended for machine processors. Kodacolor II film could not be processed in the recently marketed Vericolor chemicals. In other words, Kodacolor II film was not simply an amateur version of the two Vericolor films. Hence, in 1972, there were three Kodak colour negative processes:-

The films and the processes could not be interchanged (but see above for advice re: processing a C-22 film in C-41 chemistry). Process

C–41 using Flexicolor chemistry

Notes.

For further information, the reader is advised to download the Kodak Booklet entitled "Processing Colour Film". It is available here as a pdf file in a version dated July 1982. “Rack

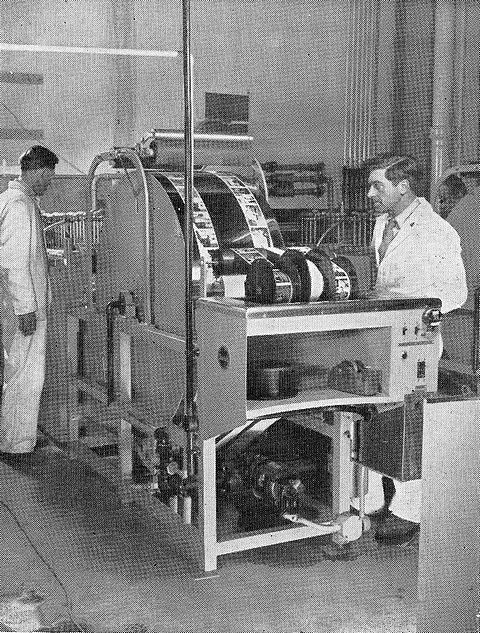

and Tank” continuous processors using C-41 Replenishment was generally automatic and the dwell time in each processing tank could be altered to suit each process, (C-22, E-3, E-4, C-41, Agfa Negative, and others including black and white films.). In the trade this type of processor was known as “Dip and Dunk”.

Notes.

A

process cross between the C-41 and the C-22 for Kodacolor II

film

Notes.

The British Journal comments: “Results with this procedure are identical to those obtained following the official procedure”. Having never printed any negatives processed in this C-41/C-22 sequence Michael Talbert cannot comment on the (print) quality of the negatives. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Process

C-41A and C-41V Process C-41A was for Kodacolor

Disc films HR, VR, and the later Kodacolor Gold Disc films. The processing procedures are given in the Kodak (UK) instruction sheet “Instructions for processing Kodacolor and Vericolor Films in Kodak Flexicolor Chemicals (20 litre and larger size packings). The sheet is dated July 1983.  |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Developer. The top layer is sensitive

to Blue light and forms a Yellow dye where the developer has

acted upon it. Oxidized Colour Developer + Dye Coupler = Dye Image. The developer will only form a dye image where the film is exposed. The three coloured dye layers together make an opposite colour image to the subject. When printed onto colour printing paper, the colour printing paper (when developed) will again form an “opposite” dye image, reproducing the original colours of the subject. Apart from the contrast in the colour printing paper being higher than a colour negative film, the paper works on exactly the same principle as the negative film. Bleach. Wash. Fixer. At the end of the fixing time the film consists of coloured dyes plus some soluble silver. Final Wash. Stabilizer. Faults. At the end of processing, if it was discovered that the Bleach had been omitted from the sequence, it would be possible to re-treat the film by washing off most of the Stabilizer and then re-processing, starting with the Bleach bath. Interestingly if, by error, an exposed sheet of black and white film was to be put through a colour negative processing sequence, it would be completely blank at the end of processing. It would be be a clear sheet of film ! The colour developer would have acted upon it, making a black and white negative image but, since there would be (of course) no colour couplers in the film, the (colour) developer would be unable to also produce a coloured dye image. When the b&w film subsequently went into the Bleach bath, all of its metallic silver would be converted into silver halide, exactly as a regular colour film. The fixer would then work exactly as with a colour film (see above) and so, following its use and subsequent wash, all the soluble silver would be removed, including the exposed black silver image, being the black and white negative image formed by the colour developer. But of course, since no coloured dye images were able to also be formed buy the developer, the total negative image would be removed and the result ? ...... a sheet of blank film ! |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektacolor Film Announced

~ 1947 Ektacolor Film Marketed

~ 1949 ~ Ektacolor Type B Sheet Film Ektacolor Type B film was a

colour negative sheet film balanced for exposure with 3200°K

lamps and designed for processing by the user. The film sizes

available in 1949 were: It was the first colour negative film in the world to incorporate coloured coupler masking. The processed negatives had an overall orange cast. The orange mask eliminated the effects of the overlapping absorbtions of the magenta and cyan dyes. The first proper data sheet for the film was enclosed in a 10 page booklet published in December 1949. It is interesting to note that even as early as August 1947 the Ektacolor Processing Kit is mentioned (halfway down page 2) with four chemical baths. The negative process for Ektacolor film was entirely different to that of Kodacolor film at that time. In 1947, the colour sensitive emulsions of Kodacolor film included a black and white emulsion which was processed after the colour development step to provide a “mask” to decrease the contrast of the colour negative. (see: Kodacolor film: 1944 to 1949) When Ektacolor film was marketed in 1949, a new Kodacolor film also became available, structurally very similar to Ektacolor Type B film, and it is thought that the processing steps for both films were nearly identical. Kodacolor was processed, as far as is known, in large “dip and dunk” machines holding many gallons of chemical solutions whereas Ektacolor type B film was to be processed by the photographer in his own darkroom using 1 gallon solution kits of chemicals. Exposure Because of the reciprocity failure of the emulsion layers of the film, the correction for a 120 second exposure was around a two stop increase over the “normal” exposure of 1 second at 8 ISO. Approximate exposure

times and speeds for 1 second to 120 seconds The designation CC-10R refers to a Kodak Colour Compensating filter of 10 Red strength. It was used over the camera lens for exposures of 120 seconds. The film could also be exposed with Clear flashbulbs. Guide numbers were suggested in the Kodak Data sheet and a compensating filter was recommended for exposure with clear flash to correct the colour balance. This was stated on the supplementary exposure data sheet packed with each box of film. The supplementary data sheet included in the Type B box (see box illustration below) gave the following filter recommendations for various light sources. The filter recommended for daylight exposures required using a film speed of 5 ISO. No filter was necessary when exposing the film to tungsten light. Suggested filters for other

light sources were: The “Kodatron” light was a portable electronic flash lamp manufactured by the Eastman Kodak Company. The 86A was a fairly strong yellow filter. Calculating the exposure

time for Ektacolor Type B Film Some useful information on the exposure of the Type B film is given in the Kodak Color Data book “Color Photography in the Studio” (first edition published in 1950), on page 59. It was suggested that an exposure time of 120 seconds should be increased by 2 stops over a calculated exposure time based on 1 second. The exposure variations listed above show a method of calculating the exposure time based on the same method as given in the later Kodak Ektacolor Type L film instruction sheet. On the last page of the Type B instruction sheet under “Color Balance and Speed Charactaristics” Kodak suggest that for critical work an exposure test is recommended, and that their production tests had been made at an exposure time of 1 second.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ektacolor Type B film dating from 1952 The Instruction Sheet and Supplementary Data Sheet, as supplied with this film, can be seen immediately after the following box images. Or download them as a pdf here. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The Instruction Sheet for the Ektacolor Type B box illustrated below, with a “Develop before” date of October 1952, is shown below. It is likely that this instruction sheet may have been one of the first issued, as the date on the last page, bottom left, is July 1949. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

At the end of the above pdf is a Supplementary Data Sheet, also issued with the film. This data sheet gives the various filters to be used when exposing Ektacolor Type B film to lighting other than tungsten 3200°K lights. As noted in the Instruction Sheet above (see page 2) “ ……. production tests are made with an exposure of ½ second”. This suggests that exposures in daylight of about 1/30 second were less likely to suffer from reciprocity effects than much longer exposures of 16 seconds or more. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ektacolor Type B film from 1956 and Type S film from 1958 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektacolor

Type B Processing Kit Originally, the working temperature of the solutions and washes was 68°F, but it was found later (1950) that the film could be processed at 75°F with a correspondingly shorter total processing time. A possible processing procedure for Ektacolor Type B film from 1949 may have been:

Notes:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektacolor

Type B processing from around 1956 ~ Process B-41.

Ektacolor Print Film, introduced in 1950, was also designed to be processed in the Ektacolor Processing Kit or the later Kodak Colour Film Processing Chemicals, C-22. The two processes did not produce matching transparencies, but the differences in colour balance were small and could be easily corrected with Kodak Colour Compensating Filters. As the baths and wash temperature was similar to Process C-22, it is very likely that the timings for the individual steps were the same. In 1958, Ektacolor Type B film was replaced by the faster “Ektacolor Type L” film for Long exposures from 1/5 second (25 ISO) to 60 seconds (10 ISO) with 3200°K lamps. The previous B-41 process became obsolete and from then on process C-22 was the standard process for all Kodak still colour negative films and Kodak Ektacolor Print film. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Proof

Printing Type B onto Black & White Paper By 1956 it is not mentioned in the Data sheet for Ektacolor Type B film and “Kodabromide Grade 3“ is recommended for making black and white prints in another section of “Kodak Color Films” data book of 1956. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Colour

Prints from Ektacolor Type B Film It might also have been possible to print a small size Ektacolor Type B sheet film negative onto Kodacolor paper using the printing machines at the Eastman Kodak laboratories where prints were being made from Kodacolor roll films. However, there is no evidence of this ever being done and it could be that the printing machines used for Kodacolor roll film were not set up for any other kind of film than Kodacolor. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektacolor

Roll Film Ektacolor roll Films were mainly purchased by professional photographers who wanted to process the film themselves, to save time, to provide negatives for printing onto Kodak Pan Matrix film making Matrix positives suitable for the Dye Transfer Process, or the negatives could be printed onto Ektacolor Print Film or, from 1955, onto Kodak Color Print Material, Type C. Ektacolor roll film was available in exactly the same sizes as the Kodacolor films, and balanced for Daylight or as Type A for Photoflood light. The roll film was processed in the Ektacolor Processing Kit in a similar way to Ektacolor Type B sheet film (see below). This leads to an interesting speculation ! If it were possible to process Ektacolor roll films, which were identical to Kodacolor roll films, in the Ektacolor processing chemicals, it may be that all Kodacolor roll films, Daylight and Type A, were processed at Rochester, N.Y. by Eastman Kodak through the same chemical baths and sequence as the Ektacolor processing kit. In his book, “Photofinishing Techniques”, the late Jack H. Coote suggests that, in the early 1950s, Eastman Kodak were using “rack and tank” machines at Rochester to process Kodacolor roll films. Ektacolor Type B sheet film was introduced in 1949, the same time that new Kodacolor 'colour masked' roll films were introduced. Both films were manufactured with built-in coloured couplers which resulted in the familiar orange-red colour negatives. Hence, it is possible that Eastman Kodak may have processed Kodacolor roll films through the 4-bath Ektacolor process starting from 1949. It is understood that, in 1957, the 4-bath process was changed to a processing sequence almost identical to the, then new, C-22 process, which had been introduced in 1956 for Ektacolor Type S sheet film and the new Kodacolor Universal film suitable for both daylight and artificial light exposures. Ektacolor Type B was replaced by Ektacolor Type L for the C-22 process in 1958. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Kodak

Ektacolor Sheet Film Type S Daylight exposures were made with a Kodak Wratten filter 85C (bluish) with an exposure rating of 25 ASA. The film was very similar to the (then) new Kodacolor Universal roll film, and the daylight exposure guides mentioned in the data sheets for either film were identical. Exposure The exposure for an average

subject in bright sunlight was 1/50th second at f/11. In 1956, the sheet film sizes available were the same as Ektacolor film type L. By the late 1950s, Ektacolor Film Type S was available in the USA to professional users in 35mm and other widths. Supplied in long rolls, it was for use in school, identification, and portrait photography. This bulk roll film version was known as “Kodak Ektacolor Film” without a type designation. By 1961, the same film was on sale in the UK to approved professional customers in 35mm bulk film format. The Kodak Professional Catalogue for July 1961 lists long lengths of 99 feet, 200 feet, and 400 feet bulk film. The film was said to have the same characteristics as Kodacolor film and, presumably, the same speed i.e 32ASA (ISO). Kodak Ektacolor Type S Film was replaced by Ektacolor Professional Type S Film in 1962.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.jpg)

|

.jpg) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Kodak Ektacolor Sheet Film Type L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

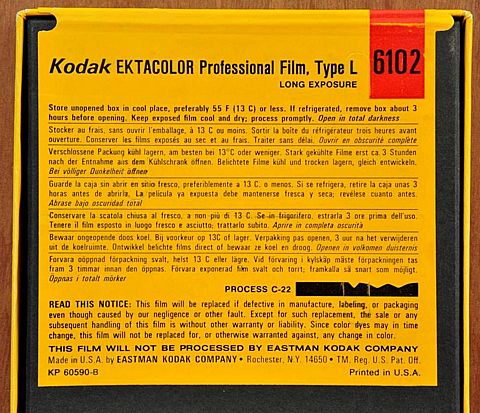

By 1958 Ektacolor Film Type B had been replaced by Ektacolor Type L, a new faster film for long exposures in tungsten light (3200°K). The film was rated at 16 ASA (ISO) for a 5 second exposure. The film was for making colour negatives at long exposure times. The 1958 instruction sheet, packed with the film, recommends exposures from 1/5th second to 60 seconds under 3200°K lamps. A trial exposure meter reading was taken with the exposure meter set at 16 ASA. If the calculated exposure was much more or much less than 5 seconds (the length of time for 16 ASA), the meter was set at the film speed in the table below nearest to the calculated exposure and another exposure reading was taken. Exposure

A Kodak Wratten 81A filter (yellow) corrected the colour balance of the film for use in photoflood lighting, converting 3200K to 3400K, for a 5 second exposure at 12 ASA. The film was rated at 20 ASA for daylight exposures at 1/5 second, with a Kodak Wratten 85B filter (yellow). For exposures shorter than 1/5 second in daylight it was preferable to use Ektacolor Film Type S. In 1958 Ektacolor Film Type L was available in sheet film sizes (inches) of : 2¼" x 3¼", 3¼" x 4¼", 4" x 5", 5" x 7", 8" x 10". The emulsion number found printed on the side of each box of film was also embossed on the code notched edge of each sheet of film excepting the 2¼" x 3¼" inch size. Kodak Ektacolor Type L film was replaced by Kodak Ektacolor Professional Type L film in 1963 (see lower). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Kodak Ektacolor Professional Film Type S ~ short exposure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

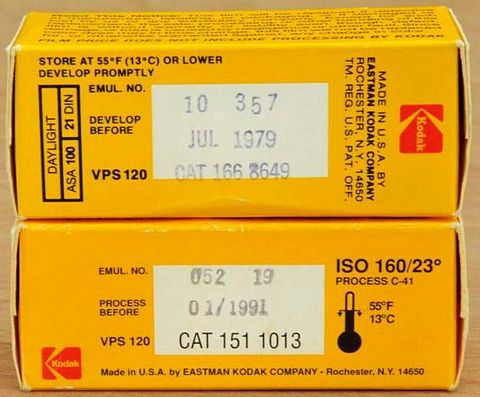

|

In 1962, a new version of Kodak

Ektacolor Type S sheet film was marketed for professional photographers. Ektacolor Professional Film Type S was very similar, but not identical, to Kodacolor X film. While Ektacolor Professional film was aimed at the professional market, Kodacolor X was principally an amateur photographer’s colour negative film, balanced for clear flash illumination and designed to be printed by photofinishers making en-prints and moderate sized enlargements. Ektacolor Professional film was often processed and printed by the photographer in his own darkroom, using enlargers with a filter drawer or colour head. Correctly exposed Ektacolor Professional Type S negatives generally required yellow and magenta filters for printing, whereas, Kodacolor X negatives, being slightly yellower, or redder in colour than an Ektacolor negative, frequently required the use of cyan filters to balance a colour print. If Kodacolor X film was exposed to daylight with a Kodak No. 85C filter over the lens, the resulting negatives were very similar in colour balance to Ektacolor Professional film Type S negatives and could be printed with yellow and magenta filters. As it was possible that amateur photographers might expose their Kodacolor X film negatives to widely differing lighting conditions, the photofinishers who printed the resulting negatives compensated for the variations in colour temperature by means of their automatic colour printing machines. To assist the photofinishers in coping with this range of variation, Kodacolor X film, and the earlier Kodacolor film, were balanced for 3800°K, (clear flash bulbs), approximately mid way between daylight and tungsten illumination. Prints made on automatic colour printing machines may have had slight colour mis-matches regarding highlight to shadow differences, (magenta highlights, green shadows as an example), but generally Kodacolor X and Kodacolor films were capable of giving a pleasing balance with most subjects. As Ektacolor Professional Film was balanced for daylight, it was to be expected that a slightly higher degree of colour accuracy was obtainable with subjects exposed in daylight conditions compared with the Kodacolor films. However differences were slight and a lot depended on the quality of the final print. In early 1963, a 120 size roll

film Ektacolor Professional Type S Film was made available. Like the previous “Kodak Ektacolor Film”, (see above), the Type S professional emulsion was also made in 35mm size and supplied in long rolls. The Kodak Professional Catalogue for 1964, (for the UK) lists Ektacolor Professional Film Type S in 120 rolls, coded “CPS 120” and bulk 35mm film in 100 ft. and 400 ft. lengths. To view a picture of a 120 roll film box of Ektacolor Professional Color Negative Film Type S (above), click here. In 1966, the speed of all Kodak camera colour negative films were increased by 1/3 of a stop, making Ektacolor Professional Film Type S the fastest colour negative film in the world at 100 ASA (ISO). In the UK, by 1970, an additional size of 70mm film was made available in 100ft lengths. Two years later, another addition was 35mm size film in 36 exposure cassettes. 220 size film was listed in the Kodak U.K. Professional catalogue by 1971. In the U.S.A., 220 and 620 size rollfilms were mentioned in the data sheet for Type S Professional Film in October 1964. Below is shown a box of Ektacolor Professional Type S sheet film, probably manufactured around mid-1963. Alongside is a box of Ektacolor Professional Type L, probably manufactured around mid-1964, so an early eample. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The first design of label to be used on Professional Type S film was “Dev. Before July 1964” (as applied from 1962; see 2nd from bottom). The top box contains film of 2¼ x 3¼ inches, packed into a 5 x 4 inch film box. Note that the lowest box, that contained 8 x 10 inch paper, has a "Dev Before" date of Sept.1965. |

This was the original label, as used from the introduction of Type S Professional film in 1962. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rear label of the “Develop Before” Oct. 1974 box (left, above), showing storage instructions in seven languages. This type of label was in use from 1970. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Kodak Ektacolor Professional Sheet Film Type L ~ long exposure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

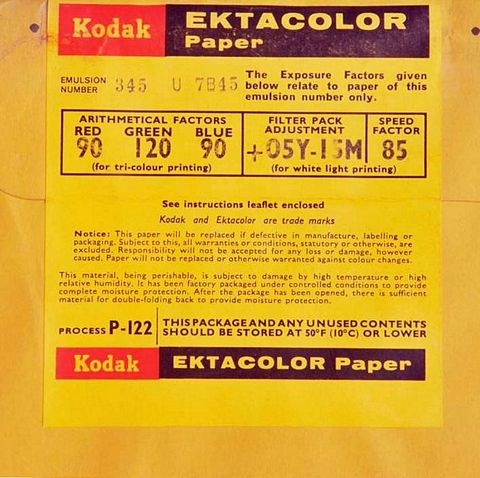

Near the end of 1963, Eastman-Kodak introduced a faster long exposure colour negative film to replace Kodak Ektacolor film Type L (see above). It was designed for exposures in tungsten lighting at times from 1/10 second to 60 seconds. Like the previous Ektacolor Type L film, the speed of the film depended upon the exposure, and the exposure was calculated in exactly the same manner as with Ektacolor Type L film.