| F.R. Print Process |

|

|

|

|

|

Fink Roslieve (F.R)

Colour Print Process The 'F.R' colour printing process

was a revised and simplified form of the Pakolor process, marketed

in the USA by the F.R. Corporation, New York 56, USA. Michael found various errors within the processing sequence printed in Jack Coote's book, presumably taken directly from F.R. Corporation literature e.g. in the column headed 'Total min. at end of step', the length of time was printed as '385' minutes. This is believed to refer to the total processing sequence time and should have read 38minutes, a time which seems feasible at the highest processing temperature - see Note 4, below. The reference to the F.R. Process in Jack Coote's books are the only ones found by Michael, apart from an advertisement in the American 'Popular Photography' magazine (not the UK version of this title), as shown here. Going by the date of the publication of these books (1963 and 1968), it could be assumed that the process was in use by (mostly) American amateurs from the late 1950s to the first half of the 1960s. |

||||||||||||||||||||||||||||||||||||||

|

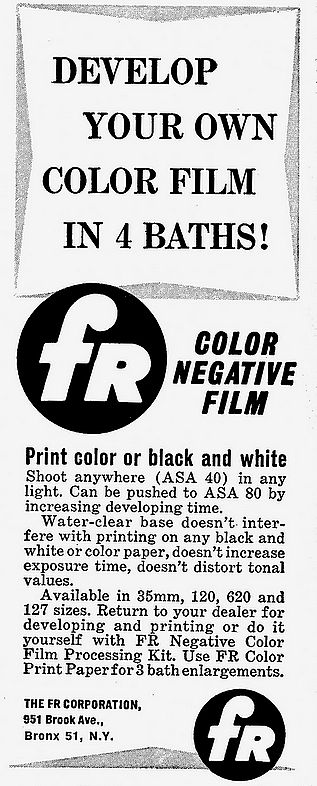

Opposite: An advertisement for 'F.R. Color Negative Film' published in the American magazine 'Popular Photography' in August 1963. It mentions an 'F.R. Negative Color Film' processing kit using four solutions and 'F.R. Color Print Paper' for three bath enlargements. It is very likely that Color Print Paper was processed in the processing sequence published in 'Colour Prints' by Jack Coote (see below). The F.R. Color Negative film

may have been very similar to the unmasked Agfacolor negative

film CN-17 which was the same speed and being unmasked, was suitable

for black and white prints and colour prints (as claimed for

the FR film). The F.R. Film advert claims "Shoot anywhere

(ASA 40) in any light". If If pictures could be taken

“in any light”, the film must have had a colour temperature

sensitivity of about 4,500 °Kelvin, approximately between

daylight and tungsten light, identical to Agfacolor CN 17

colour negative film. Colour corrections for differently balanced

lighting conditions were then made at the printing stage. The F.R. Print Process, presumably for dish processing.

Total time excluding drying: 43 minutes. Notes:

|

|

|||||||||||||||||||||||||||||||||||||

|

J. Coote mentions the F.R. process again in his next book “Colour Prints” published in 1968, third revised edition. He says: “The colour paper marketed by Paterson is a direct descendant of earlier papers devised and manufactured by Dr. Kurt Jacobson. The earlier version of the paper and the process were first handled by Pakolor and later by the 'F.R. Corporation' before being taken over by Pavelle. The paper is now known as Paterson Colour Paper and is being distributed by Johnsons of Hendon.” It seems the chronology of the Pakolor, F.R and Pavelle papers went as follows: Pakolor paper 1952. As far as is known, F.R. paper was never sold in the UK. |

||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|