| Ansco Printon & Plenacolor ~ Researched by Michael Talbert |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

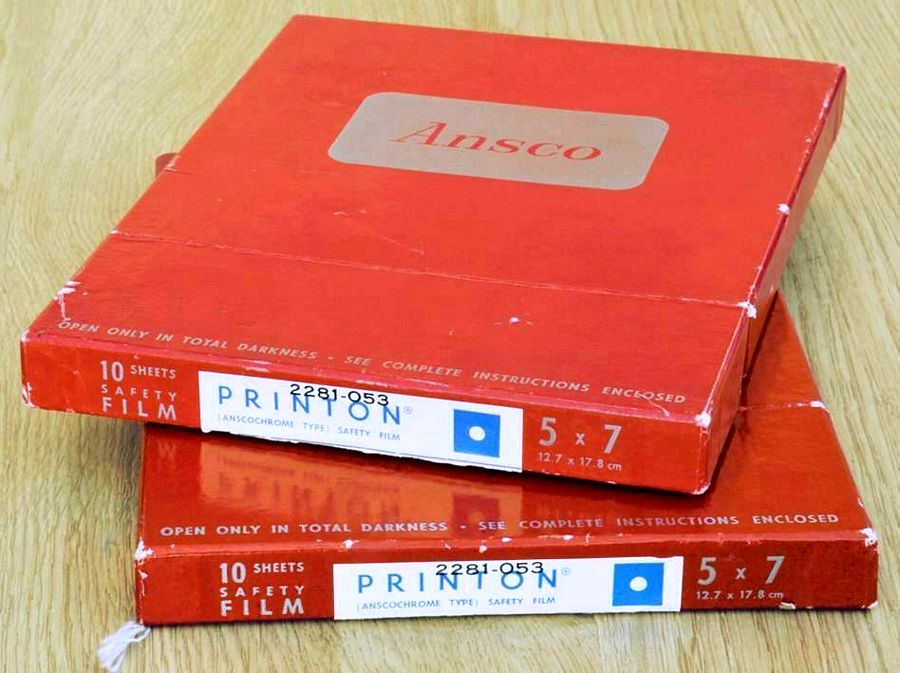

Ansco Color Printon was a reversible opaque colour print material for making colour prints directly from colour transparencies without the use of an internegative. It was first made in 1943 by Ansco, Binghamton, New York, USA for industry and the US military, but by 1945 it was sold directly to professional photographers and amateur photographers.

A detailed history of Ansco

can be read on the Wikipedia webpage here. It was the first colour print

material in the world of the integral tri-pack type where the

user could expose and process his own colour prints. The emulsions

were coated onto a white opaque colour film type of material

with an acetate base, not a paper base, similar to a thick sheet

film. It was slightly thicker than the Kodak single weight black

and white printing paper available in WW II, and was much like

the material used by Eastman Kodak for making their Minicolor

prints from Kodachrome transparencies. From the base upwards

the first emulsion was the red sensitive layer containing the

cyan coupler which gave the cyan dye image. On top of this layer

was coated a green sensitive emulsion containing the magenta

coupler. This produced the green dye image. Because the red emulsion

and the green emulsion were both sensitive to blue light, a yellow

filter was inserted between the green emulsion layer and the

top layer, sensitive to blue light and contained the yellow coupler,

producing a yellow image. As Printon was a reversal material, the first solution in the processing sequence, a black and white developer, produced a black and white negative image. Any photographic material developed to a negative image also contains an undeveloped, and unexposed, positive image, the exact reversal of the black and white negative image. This remained undeveloped in the black and white developer because it was unexposed. Printon makes use of this fact by exposing the undeveloped positive image to light, (because it was unexposed), and then developing this image in a colour developer which reacts with the colour couplers to produce a coloured positive image, the exact opposite of the black and white negative image. At the end of the colour development step there are a black and white negative image and a colour positive dye image in the Printon. We only want a colour positive dye image, but the Printon contains the developed silver produced in the black and white developer and the colour developer. So the next processing step is the Bleach bath, which converts all the metallic silver into silver halide. The silver halide is made soluble by the following bath, which is the Fixer. Most of the soluble silver halide remains in the Fixing bath, and any left in the Printon is removed in the final wash. The unwanted black and white negative image, because it had been produced in a black and white developer, is unable to generate a coloured image, and is completely removed. The silver is also removed from the positive colour image, produced in the colour developer, to leave the dye image containing cyan, magenta, and yellow dyes, making up the original scene. The final wash removes any chemicals and silver not retained by the Fixing bath, and an “Anti-Staining” bath completes the processing sequence before drying. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Handling

Printon in the darkroom Exposure

of Ansco Color Printon At the time of the introduction of Printon very few photographers would have had any knowledge of making prints from a colour transparency onto an unknown tri-pack material. Some were skilled in making Tri-Chrome Carbro or Kodak Wash-Off Relief prints (later known as Dye Transfer) from colour transparencies, and would have had the necessary skills to recognize colour casts in Printon test prints. But the method of filtering, or removing colour casts, from Printon would have been entirely different to changing the colour balance of these “assembly” type printing methods. Colour casts on Ansco Printons were removed by the use of colour filters, much the same way as colour negative/positive printing, but with the opposite effect. Ansco probably had in mind a person doing colour printing for the first time, so their colour printing filters were fairly easy to use. And to help the 'first time' printer expose his first test strip, each label on the packets of Printon carried a “starting filtration” which could be made up of Ansco filters for a trial test print. Of course, because of the vast range of enlargers, enlarging lamps, and methods of printing, this trial filtration could only be a rough guide, and it was extremely unlikely that the first test print at this filtration would have produced a neutral print. But it was at least a good starting point. An exposure time recommended for the first trial print was 2, 4, 8 and 16 times the exposure time given to a successful black and white print made on Ansco Brovira contrast grade 2 (possibly Normal grade) paper. Ansco also pointed out that a heat absorbing glass was essential when using Printon, as was a U.V. filter, such as Ansco Color UV-16P. A Kodak Wratten 2A filter was a good substitute. Without the heat absorbing glass in the enlarger, it was possible that some prints would have required a very high cyan filtration to eliminate heavy red casts caused by the lack of the heat absorbing filter. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Processing

Printon with the 'Ansco Color Printon Developing Outfit' Owing to the emulsions of Printon being coated onto a white plastic base material, sheets of Printon could be loaded into “groove” type film processing hangers where the sheets were slid into grooves which held them securely on all four sides. “Clip” hangers could also be used where a clip gripped each corner of the sheet. Ansco

Color Printon Processing Procedure dating from 1948 Processing was carried out at any temperature between 65°F and 75°F, but the processing times of the two developers varied by ½ minute (First Developer) and 1 minute (Colour Developer) for each degree F, upwards or downwards. The bleach times were also variable according to the temperature of the solution. During the 1950s the processing times were changed slightly. The two development times were altered and there was a shorter Bleach time. Agitation in each solution: constantly for the first minute, then 5 seconds every minute. The process can be carried out in white light after 1st wash.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Printon

Processing Formulae from the mid-1950s The following quantities in grams make up one litre of each solution. First Developer

Short Stop; This solution is used twice, so best to make up two lots of 1 litre and use separately.

Colour Developer

Note: Hardening Bath

Bleach Bath

Fixing Bath

Anti Stain Bath (optional)

Capacity of solutions is approx: 5 sheets of 8" x 10" per litre, except for fixer which is double i.e. 10 shets of 8" x 10" per litre. Life of solutions in stoppered bottles: 1st Developer, Short Stop, Bleach, Fixer – all one month. Colour Developer, Hardener – about 1 to 2 weeks (likely to refer to after first use, so the solutions would keep slightly longer unused). |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Anscochrome

Type Printon processing procedure dating from 1960

Total time excluding drying: 73 minutes. Notes.

1968 Processing Sequence giving times for 68°F and 75°F.

Total time excluding drying: 76 minutes 10 seconds (68°F), 64 minutes 40 seconds (75°F) Notes:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ansco

Color Compensating Filters for use with Ansco Printon The Yellow filters were coded

as: 23, 24, 25, plus a 26, introduced later. Early instruction sheets for Printon state that there were just these three yellow filters, but certainly by 1948 there was an additional Yellow 26 filter included in the set. Ansco Color Compensating filters were fabricated so that any filter of any colour has twice the strength of the preceding one, the Nos. 23, 33, and 43 being the weakest filters in the set. Thus, a Yellow 24 has twice the strength of a Yellow 23, but half the strength of a Yellow 25. A Magenta 36 was equal to eight Magenta 33 filters.

The labels on the packets of

Printon stated a trial filtration, such as: “Recommended

filter combination for use with this emulsion: 1 - 23

and 1 - 43”. Colour casts were removed by placing the opposite colour filter to the colour cast in the filter draw. If the test print turned out with a “Blue” cast, a Yellow filter was placed in the filter draw for the next trial print. The strength of the filter was according to the strength of the colour cast, a heavy colour cast would need a strong filter to bring the colour balance to neutral. In an article published in the British Journal of Photography Almanac for 1954 on making and processing Agfacolor prints, there is a table giving comparative strengths of Agfacolor printing filters, Kodak Compensating filters, and Ansco Color Compensating filters. The weakest Ansco filters, Nos. 23, 33, and 43 are given as equal strength to a 10 value Agfacolor filter, or a CC05 Kodak filter. The highest value Ansco filters, Nos. 26 and 36, have an equivalent value of an 80 Agfacolor filter, or a CC40 Kodak filter. The author of the article wisely states that “…the table of equivalent filters are probably not identical to those of Agfa……”. Kodak Colour Printing filters were not in existence in 1954 but the “CC” range was being used for colour printing. The Agfacolor filters at that time would have been separate glass filters, and although Agfacolor Heads incorporating “dial in” filters had been in use for about five years; it is fairly certain that the article refers to the glass filter set. The article also states “……….Ansco Printon correction filters have proved quite satisfactory to eliminate even serious colour casts.” Ansco suggest in their literature

a method of writing filtrations by listing the filters used in

columns equivalent to the Nos. 23, 33, and 43 filters.

Athough this appears to be a very laborious way of writing filtrations, and prone to errors when copying the figures is concerned, it may have been suggested to help beginners in colour printing to become proficient at filtering colour casts and to work in “eights” of the 26 and 36 filters. Ansco mention that it was never

necessary to include yellow, magenta, and cyan filters together

in the same filtration, as this only served to increase the exposure

of the print.

This filtration was equal to two 23 Yellow filters and one 33 Magenta filter, as the top row cancelled itself out. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The rear label of an Ansco Printon box dating from 1961. A “starting filtration” is suggested of one 10 Magenta filter and one 10 Yellow filter. By the late 1950s the earlier Ansco Color Compensating filters of 23,33,43, series (see above) had been replaced by this more conventional numerical system of filter designation. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Exposure

factors for Ansco Color Compensating Filters When removing filters, the exposure time was divided by the appropriate factor. These exposure factors applied to each filter regardless of the colour of the filter. In practice, as the printer gained experience in colour printing, he often disregarded the factors and worked out the exposure times based on his experience on making previous prints. If a large change in the filtration was necessary, a stepped exposure test strip could be made. Colour reversal print materials generally had much more latitude in their exposure times than negative – positive printing papers. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

End

of Printon in 1973 By the early 1970s, Ilford’s Cibachrome Print material was making a favourable impression. The total wet processing time of the Cibachrome Print material had been reduced from 47 minutes for the 6 solution P-7A process of 1969 to 16½ minutes wet processing in 1974 using the, then new, P-18 process with only three solutions. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

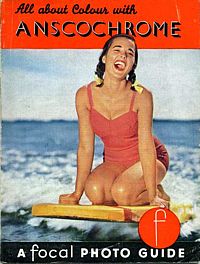

The

Amateur Photography diary for 1959 gives information relevant

to Ansco colour transparency film. Further appears in a Focal

PhotoGuide booklet, "All about Colour with Anscochrome",

written by Keith Hornsby and published in 1959 (see cover image,

left).

The

Amateur Photography diary for 1959 gives information relevant

to Ansco colour transparency film. Further appears in a Focal

PhotoGuide booklet, "All about Colour with Anscochrome",

written by Keith Hornsby and published in 1959 (see cover image,

left).