| Cibachrome (the Silver Dye Bleach Process) |

|

|

Michael Talbert |

|

| In April 2020 I learned from Suk Fong Chun, who is taking a Master’s Degree in Photograph Conservation, of a website called the 'Cibachrome Association'. It is a group founded by the original Ciba and Ilford Imaging professionals, after their Marly centre closed in 2013, see https://association-cibachrome.com/. The website is written in French. | ||

|

Introduction Unlike conventional colour negative/positive printing papers, where the coloured dyes making up the picture were generated by colour couplers in a “colour developer”, Cibachrome print materials were manufactured with the dyes already incorporated in the printing paper. Cibachrome materials, or papers, were multi-layer products, each layer containing a dye of the opposite colour to the layer’s sensitivity. The top layer was sensitive

to blue light and contained a yellow dye. One problem for any Silver Dye Bleach materials was their extreme insensitivity to light. This is because each layer has effectively a complimentary colour filter coated on top of the sensitive emulsion of that layer. For example, the top layer, sensitive to blue light, has a yellow dye placed over the blue sensitive emulsion, the opposite colour of blue. The later Cibachrome print materials were manufactured with an extra emulsion layer coated adjacent to each of the dye containing layers. These extra layers contained no dye, but were in contact with the dye containing layers and served to increase the speed of the print paper. Early

History; Gasparcolor The first person to achieve any success with the Silver Dye Bleach process was the Hungarian chemist, Dr. Bela Gaspar. Based on the work of another researcher, Carl Schinzel, Dr. Gaspar invented a colour transparency material for use with motion picture animated advertising films in the early 1930s. The films were made using a very complicated method, by making three exposures of each frame through tri-colour filters on black and white motion picture film. This produced a separate negative record of the red, green, and blue components of the picture. Because Dr. Gasper’s material was a positive to positive printing material, each frame had to be printed again onto the black and white motion picture positive film to produce a transparency of each of the red, green, and blue records. Finally the black and white transparencies were printed through their corresponding tri-colour filters, a red record black and white transparency was printed through a tri-colour red filter (and so on) onto Dr. Gaspar’s colour Dye Bleach material to produce a colour motion picture film. If Gaspar’s material had been made in large sheet film sizes, it could have been used to make duplicate transparencies, possibly from Autochrome, Dufaycolor, or other additive “reseau” transparencies. (Kodachrome 35mm film was first marketed in 1936). This was never done, but by 1945 a printing material known as “Gaspar Opaque”, similar to a reversal colour printing paper, was being made and sold in America for photographers to make their own colour prints from transparencies. Another material, maybe an improved version, appeared in 1953. This later material was known as “Gasparcolor DP” (Direct Positive). It was obtainable in the USA, was similar to Cibachrome, and processed in much the same way. It was balanced for enlarger lamps (3200°K), and had to be handled in total darkness or under a safelight suitable for panchromatic black and white films (Wratten Series 3, or 5, or Ilford GB 908). It was said that with a brightness level of 10 foot candles, prints from “average” transparencies could be made with exposure times of 30 to 60 seconds. There was even a recommended filter pack for trial exposures given with each batch of Gasparcolor DP, possibly similar to the “Grundzahl” figures stamped on each packet or box of Agfacolor paper. Processing

Gasparcolor DP A stop-bath in step 2 was optional. If used, 30ccs of glacial acetic acid in 1 litre of water would have been a suitable formula. A dozen sheets of 8 inch x 10 inch

Gasparcolor DP could be processed in 2 US gallons

of Developer or Dye Bleach. 2 US gallons

of Silver Bleach served to process twice this amount of print

material.

Notes:

|

||||||||||||||||||||||||||||||||||||||||||||

|

Ilford

Colour Prints (Ilford Colour Print Material) In the early 1950s, no printing or processing machines were obtainable or sold in the UK for mass production printing of transparencies onto a print material. Ilford designed and made their own equipment, both printers and processors, for their colour print service. Instead of printing onto a multi-layer colour coupler type of paper, such as Anscocolor Printon, Ilford chose to employ a Silver Dye Bleach material. It was known as “Ilford Colour Print Material”. Because of the extremely low light sensitivity of Silver Dye Bleach materials, the printing machines were equipped with 2¼ kilowatt Xenon arc lamps to make the printing exposures and thus achieve a reasonable print production rate of over 1,000 prints per hour. The printing paper, or Silver Dye Bleach material, was allegedly made by Ilford Ltd, but was only for use in their laboratories for their print service. It was never sold on the open market, much in the same way as Eastman Kodak’s Kodacolor paper. From

1963 In 1963 Ciba AG, Switzerland, approached Ilford with a buy-out offer. The Ciba group comprised (i) Ciba AG, Ciba Photochemie AG (formerly Tellko AG, research laboratory near Fribourg) a manufacturer of sensitised photographic materials, (ii) Lumière SA France (near Lyons, acquired by Ciba in 1962) also a manufacturer of sensitised materials & of colour film (in the 1950s), and (iii) Gretag GmbH (Germany) a designer and constructor of equipment and instruments for use in the photographic industry. There was no take-over by Ciba until 1969 but there began commercial co-operation between Ciba and Ilford to develop Ciba's dye-bleach print material for making prints directly from colour transparencies. Originally called Cilchrome ('Cil' derived from the names Ciba, Ilford and Lumière) the eventual product name reverted to Cibachrome (1969 in the UK). A processing procedure for “Cilchrome” was published in the British Journal of Photography for 19th June 1964, by E.Ch. Gehret. It was also reproduced in the British Journal of Photography Annual for 1965 and some following annuals. The chemical formulae, given in the annuals, were worked out by E.Ch. Gehret. It is not an exact procedure, the material was still at the “research and development” stage at the time the processing procedure was published. It is based on some of the patents taken out by Ciba Photochemie.

Notes:

|

||||||||||||||||||||||||||||||||||||||||||||

|

The

Cilchrome Process How

Silver Dye Bleach Materials work The respective layer records the red, green and blue coloured image of the transparency, plus mixed colours, being recorded in two or, in the case of white, in all three layers. After exposure, the material is developed in a black and white developer, fairly similar to one which might be used to develop black and white printing paper. This produces a negative silver image in each layer corresponding to a black and white negative of the red, green and blue components of the transparency. For example, the image in the middle layer is a black and white negative of anything green in the transparency, or any colour which is partially green. A cyan colour, green/blue, would be recorded partly in the green layer and partly in the blue layer. The next step is the Dye Bleach bath. The removes the coloured dye from the developed black and white negative image only, and leaves any dye not affected by the black and white developer. It works in the exposed parts of the red, green and blue images only. The remaining dye makes up the positive image to give a colour print of the transparency. As the material still contains the unwanted exposed and unexposed silver halide, two more processing steps are necessary. In the next step i.e. the Silver Bleach step, the exposed metallic silver, formed by the black and white developer, has to be converted into silver halide which will be made soluble in the fixer. The final chemical step is a Fixing Bath, which converts all the silver halides in the material, exposed and unexposed, to a soluble silver, which can then be washed out the print to leave only the dyes. The negative image is effectively “removed” from the Cilchrome (Cibachrome) print, the negative unwanted dye is bleached out in the Dye Bleach, and the exposed silver halide of the negative image is “removed” in the Silver Bleach and Fixer. This is an outline of the earlier processing procedure. Later processes combined the Dye Bleach and Silver Bleach into one processing step. Earlier processes contained additional fixing baths as well as a separate Dye Bleach and Silver Bleach. Image

Sharpness and Dye Stability in Silver Dye Bleach Materials Unfortunately, there are very few colour developing agents that can be used successfully to produce coloured dye images. Also, the dyes which these colour developing agents produce have poor stability to light and are susceptible to heat, humidity, and chemical fumes, even in dark storage e.g. colour prints in an album. Because Silver Dye Bleach materials do not have to generate a dye image by processing the material in a “colour developer”, there is far more choice of dyes which can be included in the three light sensitive emulsions. Cibachrome Print and Transparent materials contained dyes of the polyazo type, having excellent resistance to dye fading, humidity and chemical contamination. Another advantage was a gain in print sharpness. There was a significant gain in sharpness in a Cibachrome print compared to a print made on conventional “colour development” paper such as the Kodak Ektachrome range papers. This gain in sharpness was due to minimal ”light scatter”, or irradiation, within each emulsion layer. In this context, “Irradiation” is light scatter within silver light sensitive emulsion layers. Light is scattered by reflection and spreads as it passes through overlapping silver grains in any light sensitive photographic material, film or paper. It causes unsharp images, as the light is spread out and definition suffers. Each light sensitive layer in a Cibachrome material had a dye of the opposite colour to that layer’s sensitivity included in the layer. The coloured dye had a masking effect on any light scatter within the emulsion layer. For example, the magenta dye in the green sensitive layer ”neutralised” any scattered light in that layer by rendering it magenta, the opposite colour to green, and therefore the opposite colour to the layer’s sensitivity. “Acutance dyes” were included in conventional colour materials, films and papers, to improve definition, but acutance dyes in Silver Dye Bleach materials are taken to an extreme level, hence greatly improving definition. The

P-7A Process From

1969 Cibachrome could be dish processed, but at no more than one sheet at a time in a processing dish. The support base was fairly rigid, slightly thicker than the base of a resin coated colour printing paper, and did not bend easily. Because of the risk of the corners of one sheet damaging another, interleaving agitation of more than one sheet was not recommended. Cibachrome Print material was to be handled in total darkness, or under a safelight fitted with a 15 watt bulb and a “Dark Brown” filter, such as Ilford 912. The near equivalent safelight filters which were suitable included Kodak Wratten 10H, and Agfa 166M, later known as “08”. This Process P-7A processing sequence was in use for Cibachrome Print (CCP) in 1969.

Total time: 47 minutes. Notes:

|

||||||||||||||||||||||||||||||||||||||||||||

|

Cibachrome

Transparent CCT-D 661 Cibachrome

P-10 Process for Cibachrome Print CCP-D 182 and Cibachrome Transparent

CCT-D 661

Total time: 36½ minutes. Notes:

|

|||||||||||||||||||||||||||||||||||

|

|

|

Cibachrome-A

and Process P-12 In 1974 there were very few colour printing materials for making colour prints directly from colour transparencies. The best known material was Kodak’s Ektachrome RC paper, Type 1993. The paper was not readily available to the amateur photographer, nor were the Ektaprint R5 processing chemicals, (see Ektachrome paper section). Although the minimum size of Ektachrome RC paper was 8 inches x 10 inches, and the packets of 25 sheets could be obtained by order through a photographic dealer, the minimum quantity of 5 gallons of each component of the Ektaprint R5 processing chemicals would have been likely to deter even the most enthusiastic amateur photographer from reversal colour printing. Cibachrome-A

processing kits 20 sheets of Cibachrome-A print

material, size 8 inch x 10 inch. These kits would have appealed to amateur photographers who had already done some negative-positive colour printing. They would already have owned some colour printing filters and maybe some of the other equipment. Cibachrome A material could equally well be processed in dishes, like black and white prints, although Ilford did not recommend this method of processing. Cibachrome-A print material was available in various sizes up to 16 inch x 20 inch. An 11 inch x 14 inch size was sold in the USA and Canada. The almost equivalent size being sold in European countries was 16 inch x 12 inch. The 16 inch x 12 inch was a useful size as two 8 inch x 10 inch prints could be printed on one sheet. To encourage amateur photographers to start making their own colour prints, especially those who were economically minded and objected to paying for a large size 8 inch x 10 inch kit, Ilford introduced “Cibachrome Discovery” kits in the USA in 1977. The kit was a smaller version of the 8 inch x 10 inch kit and contained 20 sheets of 4 inch x 5 inch Cibachrome-A print material plus a mini 4 inch x 5 inch processing drum. Also included were the set of printing filters, slightly smaller at 3 inches square, measuring cylinders and processing chemicals to process the 20 sheets of 4 x 5 inch paper. Cibachrome-A kits were being sold in European countries by 1976. It seems the "Discovery" kits were sold in Europe (presumably including the UK) from 1978. They were known as “Cibachrome Mini Kits”, but included the same contents as the US "Discovery" kits. Economically, the kits were an excellent “buy” for any amateur photographer who had no previous experience of colour printing, and was not keen to spend too much money in case they found colour printing too difficult and found more pleasure from making black and white prints. The huge advantage of the Cibachrome-A process was that the complete beginner could make prints from colour transparencies and not colour negatives. The filtering, i.e. changing the colour balance of the print, was much more logical than printing from negatives. When printing from transparencies, a colour cast was always corrected with a filter of the opposite colour to the cast. There was the added advantage of using the transparency as a colour guide. If the transparency had a definite colour cast, something easily seen in a transparency but very difficult to detect in a colour reversed negative, a filter of the opposite colour to the cast could be added to the “filter pack” for a first test strip for an improved colour balance in the print. Cibachrome-A

print material CCP-A 182E The material was designated “CCP-A 182E”. It was only available in a highly glazed surface, similar to Kodak's colour printing papers of surface F. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Printing

filters To assist the printer in achieving the correct colour balance, basic filtrations for four types of reversal films were printed on the back of every packet or box of Cibachrome-A material. Generally the filtrations were made up of yellow plus cyan units, such as 60 – 40, (60 yellow, 0 magenta, 40 cyan), and it was recommended to expose a first test strip using one of the filtrations given, appropriate to the make of transparency being printed. The filtrations given were only a starting point, and it was extremely unlikely that a correctly balanced print would result from the first trial. The filtrations printed on the packets could also be used to calculate the differences in colour balance between different batches of Cibachrome-A paper. When filtering Cibachrome-A material, large changes in filtration were often necessary. Unless the print was extremely close to the correct balance, changes of less than 10 units of any colour would not be enough to make any significant difference to the colour balance. A strong cast could be corrected by a 40 unit Cibachrome filter (or equivalent Kodak colour printing filter). P-12

process for Cibachrome-A material This process is for processing in the drums provided with the kits. There was a choice of three processing temperatures. Load drum in total darkness.

Total times: 13½, 12 and 10½ minutes (excluding drying time). Notes:

In the book "How to do your own Developing & Printing" by Philip Weston (published around 1977 by Dick Crane), the author, after extolling the simplicity and virtues of the Cibachrome P12 process, includes some cautionary comments:

In conclusion, Philip Weston summarised: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

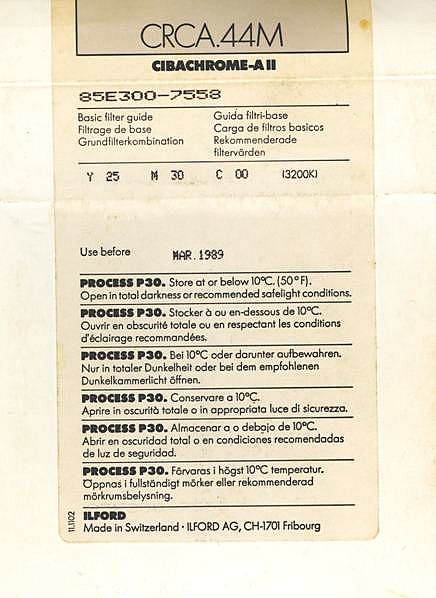

Cibachrome-A

II paper using Process P-30 chemicals It had been found that, in general, the contrast of the previous amateur Cibachrome print product, CCP-A 182E, was acknowledged to be too high. The new improved materials, according to the British Journal of Photography Annual for 1983, “Offers improved gradation and better skin tones. The improvements are accomplished by what is in effect, a chemical masking effect which gives a higher contrast and speed in the yellow dye layer when this is exposed by blue light than when it is exposed by white light.” The new Cibachrome-A II had about 20% more yellow dye per unit area giving a higher yellow saturation and was offered in two surfaces, coded CPSA.1K, and CRCA.44M. Ilford claimed "improved colour reproduction, improved colour saturation and improved contrast control characteristics". CPSA.1K was described as a

“De Luxe Gloss” on a polyester base. The prints had

a very high gloss finish, much like a highly glazed black and

white glossy print. It was recommended that all Cibachrome-A II materials be handled in total darkness. It was possible to handle them under a safelight suitable for panchromatic black and white films, Kodak Series 3 or Ilford GB 908, provided direct light from them was only used to view a clock or enlarger timer. Cibachrome-A II materials were processed in P-30 chemicals. Kits of P-12 chemicals were not suitable for processing the new print materials, nor were the P-30 chemicals any use for the old Cibachrome-A paper. The standard temperature for the P-30 process was 24°C (75°F), but it was possible to process at temperatures from 20°C (68°F) to 29°C (81°F). Chemical kits for amateur processing were available in 1 litre, 2 litre and 5 litre sizes, the 2 litre and 5 litre kits could be made up in 1 litre batches of each of the solutions. As with the P-12 process, the three solutions were Developer, Bleach and Fixer. The P-30 process was designed principally for Drum processing, where the print was loaded into a light tight drum and then, through a light trapped entry, the appropriate quantity of chemical solution was added before the drum was then rolled backwards and forwards on a flat surface to agitate the solution or wash water. A better approach to processing was to use a processing drum which was contained in a thermostatically temperature controlled water bath, included in a machine which agitated the drum with an electric motor. Although more expensive in set-up costs, a drum rotating in a water bath gave far more reliable and consistent results. The water bath would also hold the four solution bottles at the correct temperature. The JOBO Drum 2800 system used with a JOBO CPE-2 processor could process prints up to 12 inch x 16 inches. Similar water bath systems were available from other manufacturers, but the Jobo was the generally considered to be the best, albeit more expensive than some rivals. It was also possible to process prints in dishes although this had to be done in total darkness up to the fixing step. This is where a safelight might be of use, as a longer time would be spent in the dark than with drum processing where the only part in “total darkness” would be loading the drum. Load drum in total darkness, or check temperature of solutions in dishes before processing. Turn on Safelight if used in dish processing.

Notes:

An example Ilford display print, sent by Peter Pearse, can be viewed here. 'Amateur Photographer' magazine, in its April 2nd 1983 edition, tested the new Cibachrome II 'prints from slides' paper and its processing chermistry. They concluded that it was marvellous, with more mellow contrast than its predecessor, true and accurate colours, excellent saturation and sharpness that was "very good indeed". To read the test as a downloadable pdf, click here. A review by 'Photography' magazine, in January 1982, can be downloaded as a pdf, here. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Alternative

'Home Produced' P30 Chemistry Michael Talbert has investigated a possible substitute processing procedure and chemistry to replace the official P-30. The following is proffered as a possible 'work around' but with NO GUARANTEE that these formulae will work. The time, trouble and cost to experiment with them will depend upon how much Cibachrome-A II paper is available to the user. The procedure includes a substiture 2-part Developer (Solutions A and B; formulae are shown below). Alternatively, a standard commercial black and white print developer should work equally well. A formula for the P-30 Dye

Bleach could not be found so the procedure below includes the

use of P-10 Dye Bleach and P-10 Silver Bleach

solutions, followed by a standard black and white Fixer (except

that the Fixer should have a pH of above 6.0. A lower pH will

affect the cyan dye). The fixer should be diluted as if processing

black and white film. Formulae for the P-10 Dye Bleach and P-10 Silver Bleach solutions are shown below, though it would be worth looking on e.g. e-Bay for old P-10 or, better still, P-30 kits of chemicals. The following processing sequence is for dish processing, but it may work in a drum, such as the JOBO drum:

The solutions should be used

at a temperature of 24°C +/- 1°C. Steps 1 and 2: P-30 Developer: For Steps 1 and 2, above, a black

and white print developer can be substituted, such as Kodak Dektol,

or Ilford PQ Universal.

Best to have a Stop Bath after the black and white developer. Step 5: P-10 Dye Destruction Bleach.

If the above Dye Bleach is used for Step 5, the process will need a Silver Bleach in Step 7 to rehalogenise the metallic silver so it can be removed in the fixer. Step 7: P-10 Silver Bleach.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The above packs

of Cibachrome-A were donated by Caroline and Alex. The left hand 25 sheet pack of Pearl finish (CRCA.44M) is dated as "Use before Sept.1986". The right hand 10 sheet pack of glossy (CPSA.IK) is dated "Use before Mar.1987". |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Cibachrome

II CTD.F7 display film A different processing sequence to Cibachrome Print materials was used to process the film and, as far as Michael Talbert can ascertain, it could only be processed at 29°C (83°F). Processing sequence for Cibachrome II CTD.F7 film in tanks in P-30 chemicals. Load tanks in total darkness. Solutions at 29°C (83°F)

Total time: 13 minutes. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Cibachrome

becomes Ilfochrome Classic Subsequently, Ciba-Geigy, no longer having any stake in Cibachrome, required that the Cibachrome name be changed. So, officially it became llfochrome Classic, but Ilfochrome, Cibachrome, or simply "Ciba" are names that remained in common useage. This name change officially took place in early 1992, announced by Ilford at the PMA Las Vegas. PMA stood for Photo Marketing Association and in 1992 their trade fair was held in Las Vegas. Amateur Photographer magazine, for week ending 22nd February 1992, carried the same information about Cibachrome becoming named Ilfochrome in its pages 8-11 entiled PMA 92 Las Vegas News. Ilfochrome Classic was tested by PhotoPro magazine Oct/Nov 1993. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

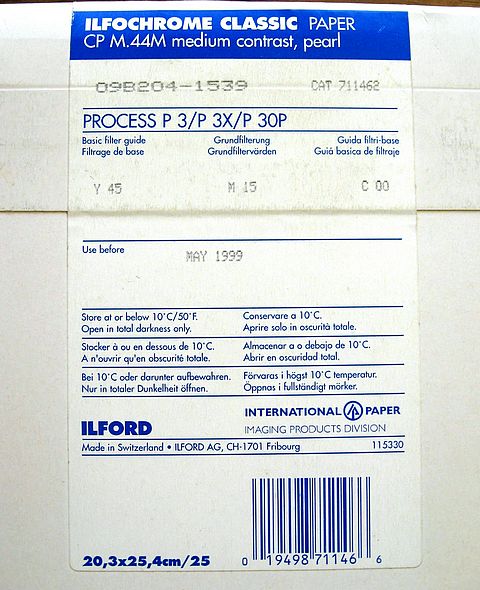

To the left, and below, are shown labels on two packs of Ilfochrome Classic paper. De Luxe CL M.1K was a medium contrast, glossy super white polyester, version of the paper, to be used with Process P30/P30P. This pack contained 10 sheets of 25.4cmx20.3cm paper and cost £11.49 (around £30 for a 25 sheet poack). The pack illustrated has an expiry date of April 1996, so probably manufactured around 1993. The basic filter guide was 45Yellow, 30Magenta, 0Cyan. Store at or below 10°C / 50°F.

CP M.44M was a medium contrast, pearl surface medium weight, version of the paper, to be used with Process P3/P3X/P30P. The pack llustrated contained 25 sheets of 25.4cmx20.3cm paper and cost around £23. It has an expiry date of May 1999, so probably manufactured around 1996. The basic filter guide was 45Yellow, 15Magenta, 0Cyan. Store at or below 10°C / 50°F.

Both packs made for ILFORD

International Paper, Imaging Proucts Division. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Processing

ILFOCHROME Classic Processing procedure. Load the processor in total darkness.

Notes.

Notes

on the Various Processes The later packet of Ilfochrome

Classic paper (see right above), type CP M.44M, also mentions

the P 3X process. P 3X and P 3XL Ilfochrome Classic process

P 3 Kit P 3.5 replaced P 30P and was designed to be used in small table top processors such as the CAP 40, ICP-42 or drum processing. It was packed as 5 litre kits. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|