| Kodak Ektacolor Laboratory Film - researched by Michael Talbert |

|

The content of this page should

not be confused with the camera films (negative

for prints and slide

film for transparencies) as used in amateur and professional

cameras (roll film, 35mm film and sheet film). Note: |

||

|

|

||

|

Colour Internegative films were designed for producing colour negatives directly from colour transparencies. The resulting negatives were then used for making colour prints or enlargements on a colour negative printing paper, or colour transparencies could be obtained by printing onto a colour print film, such as Vericolor Print Film. Although more direct methods of making colour prints directly from colour transparencies have been used since 1941, a colour internegative generally gave a far better reproduction of a transparency compared to a print made using colour reversal paper (see Kotavachrome prints and Kodak Colour Print Material, Type R) In the 1930s to 1950s colour prints were also being made from colour transparencies by the Tri-Chrome Carbro and Dye Transfer processes (not described here). History;

Earliest 'Colour Internegative' films for still photography Eastman Kodak introduced “Eastmancolor Internegative Film Type 5243” in 1951 for use in the Motion Picture industry. It is possible that internegatives were made on this film from release prints made on “Eastmancolor Print Film, Type 5381” . In the USA, Eastman Kodak began a service in 1949 for making colour prints from amateurs’ colour transparencies. The transparencies, mainly 35mm, were printed onto Kodacolor (camera type) film, possibly Type A, and then prints were made from the internegatives on Kodacolor paper. Agfacolor

ZN film As far as can be found, the film was available in 35 mm format only, supplied in tins of 10 metre lengths from 1956. It was presumably an unmasked film, similar to Agfacolor films CN14 and CN17, possibly balanced for tungsten illumination. |

||

|

It is not known if ZN film was ever manufactured in sheet film format or if the film gained the usual colour correcting "orange" masking system in the early 1960s (at least by 1965). It is mentioned in "Agfacolor" by H. Berger in several editions that, although transparencies could be exposed directly onto the ZN film, better results were obtained by making a black and white contrast reducing 'mask' from the transparency and then exposing onto ZN film with the 'mask' in place on the transparency. As this method of "contrast reducing" was suggested, it is very unlikely that ZN film had the same "contrast reducing/contrast increasing" properties of Kodak's Ektacolor and Vericolor Internegative films, where the exposure controlled the contrast. In 1966, ZN film was available in 10 and 25 metre rolls of 35mm and 15 metre rolls in 61.5 mm width. The film was still for sale

in 35mm format only in 1980. The film was processed in exactly

the same chemicals as any Agfacolor negative film (excluding

the Agfacolor films designed for the C-41/AP-70 processes). On a personal note, Michael Talbert met someone who, allegedly, knew something about this film. During the 1970s, while working as a colour printer in London and during a discussion with other printers, Agfacolor ZN film was mentioned. One of the printers was a German lady who ventured to say she had used, or at least knew, something about the film. When asked if it was any good, she replied “Rubbish !”. To the left is shown a tin of 10 metres of 35mm Agfacolor ZN film. As there appears to be no “Develop Before” date printed on the tin, the age of this film is unknown. The label states “Agfa Aktiengesellschaft Leverkusen”, therefore it is most likely that this tin of film dates from pre-1964. Most Agfa products manufactured after 1964 carried the name “Agfa-Gevaert” somewhere on the label. |

|

|

Ektacolor

Internegative Film The recommended procedure was to make a contrast reducing mask from the transparency onto Kodak Pan Masking film. This was registered and attached to the transparency when enlarging and exposing the transparency onto Ektacolor Type B or Type L film. The mask then reduced the contrast to the level that could be accommodated on the Ektacolor films. Printing the transparency directly onto Ektacolor film did not work as the internegative would be far too contrasty and the print would exhibit burnt out highlights and dense shadows with no detail in them. The author has tried this method of making internegatives on Ektacolor Professional Type L film and came to the conclusion that only an extremely soft contrast transparency would give an acceptable result. Prints made from internegatives made on Ektacolor Type B and L films, in which the colour laboratory had taken the trouble to make the internegative from a masked transparency, gave good results, but the masking was a separate and time consuming procedure and added to the cost of the internegative. In 1961, Eastman Kodak introduced “Ektacolor Internegative Film” in sheets, and “Internegative Color Film” in 35mm rolls. Transparencies could be printed onto these film without the need for masking. Ektacolor Internegative Film is mentioned in the Kodak Data book, “Color Films”, 4th edition, published in December 1961. The book mentions that “Information on producing internegatives on this film could be obtained by request from the Sales Division at Eastman Kodak, Rochester 4 N.Y.” In the UK, in the “Kodak Professional Catalogue” for 1963 the 35mm version of internegative film is listed for sale in lengths of 80 feet. Ektacolor Internegative film in sheets was introduced into the UK in 1963. The film is first mentioned in “Kodak Professional News” for March 1963 with almost a page of description and warns that the film requires a “special developer and starting solution” and that the film and developer chemicals are not classified as a “stock line”, which means they had to be specially ordered. Not listed in the UK Kodak Professional Catalogue for July 1963, the Kodak “Trade Circular” for September 1963 lists the film in three sizes as a “new” product, and Ektacolor Internegative sheet film was later included in the Kodak Professional Catalogue for July 1964. In this UK catalogue for 1964-65, three sizes were offered for sale – 4 x 5 inches, 5 x 7 inches and 8 x 10 inches. Ektacolor Internegative film in sheet film format was designed to make internegatives at exposure times of 1 to 16 seconds with a 3200°K light source. Most internegatives were made through an enlarger with a colour head, enlarging 2¼ inch square transparencies onto 4 x 5 inch sheet film to make an internegative about 3¾ inches square from the whole of the transparency. 35mm transparencies were enlarged to about 4¾ x 3 inches and negatives from 5 x 4 inch transparencies were made to 3½ x 4½ inches. The larger the print ordered from the transparency the larger the internegative. 10 x 8 inch negatives were not uncommon when making mural sized prints. |

||

|

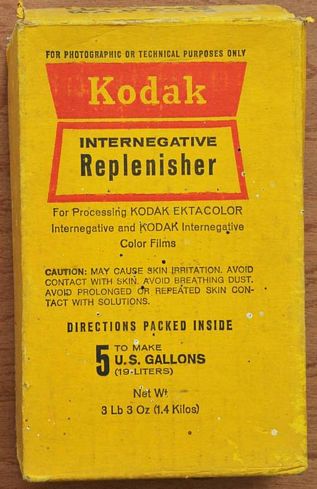

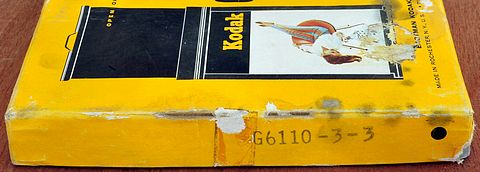

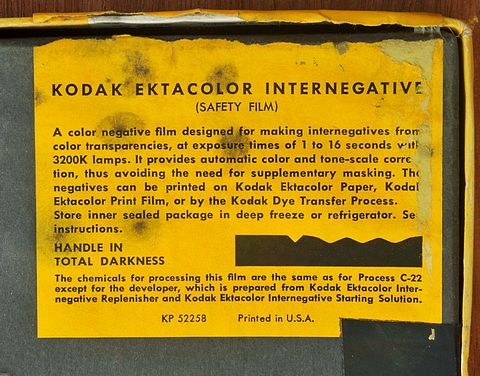

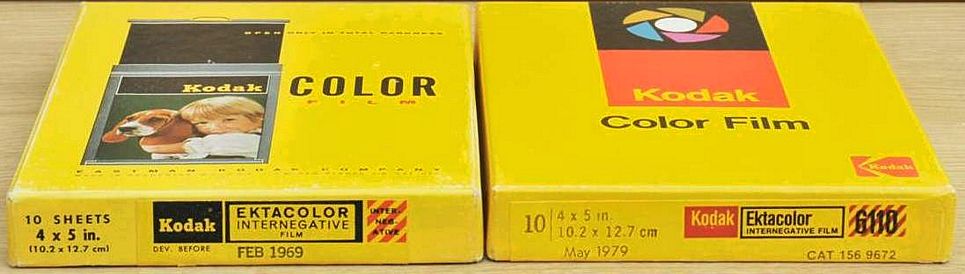

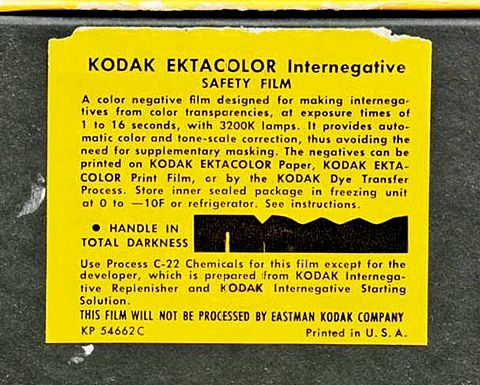

Below is shown a box of 4 x 5 inch Ektacolor Internegative film dating from 1962. The “Dev. Before” date stamped on the rear of the box is May 1963. Most types of Kodak Colour Sheet Film had an expiry "Develop Before" date of one year from manufacture. Ektacolor Internegative film supplied in sheets was introduced in 1961. By the time this box was manufactured, possibly in September 1962, this was only the third emulsion, viz: G6110-3-3 (see side of box, to the right) A description of the film on the rear label (below right) shows that the method of using the film changed little from 1961 to 1979. The only change was made in the mid-1970s when the shortest exposure recommended was changed from 1 second to 1/10 second. This is thought to be the original label as used from the time of introduction. The number on the label is KP 52258, without any additions like a or b, that would denote the label was a reprint of an earlier label. Because of this, it is reasonable to assume that the label dates to 1961 and is the original one. Notice that the special developer (prepared from Kodak Ektacolor Internegative Replenisher and Kodak Ektacolor Internegative Starting Solution) was used from the start of production of the film in 1961. |

|

|

|

|

|

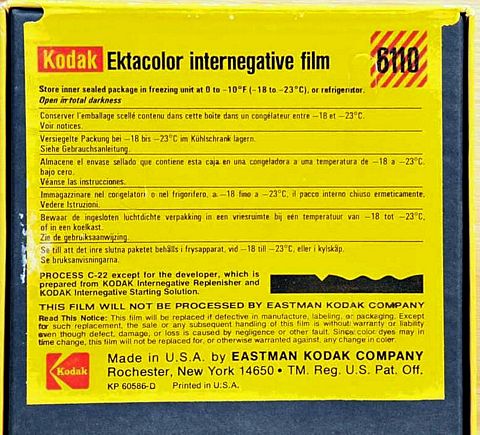

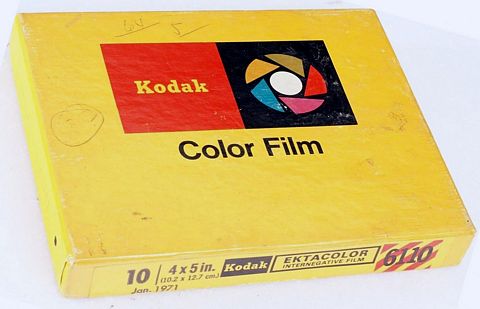

| Below are shown two boxes of Ektacolor Internegative film dated over 10 years apart. The method of exposing the film hardly changed during the life of the film, 1961 to 1979, apart from the minimum exposure time being decreased from 1 second to 1/10 second in the mid-1970s. Also by the mid-1970s, the catalogue No. was being printed onto the labels. “May 1979” (RHS box) is the advised “Develop Before” date. It is possible that this box of film was from one of the last batches of Ektacolor Internegative film manufactured. | ||

|

||

|

|

This type of label, in varying forms, was introduced for colour sheet films in 1969. |

|

|

|

|

|

Balancing

the exposure and 'shadow to highlight' balance for batches of

Internegative film The suggested starting exposure was 10 seconds and, with the filtration of 50 20 --, three or four trial internegatives were exposed at different apertures, keeping the exposure at 10 seconds. When processed and dried, one of these tests would have been correctly exposed, or very nearly so. A correctly exposed internegative tends to look slightly “thinner” than a correctly exposed camera film negative, such as a negative made on Vericolor or Ektacolor films. The best possible print was then made from the chosen test internegative, concentrating on filtering the mid tones to the correct balance If the mid tones had been filtered as near as possible to a fairly neutral balance, it is likely that the high lights would show a colour cast, and the blacks and shadow areas would show the opposite cast. For example, if the colour cast in the high lights was Magenta, the shadow areas tended to look green. This meant that the contrast of the green sensitive layer was too low. In this case, it was possible to correct the balance of the print by adding a filter of the same colour cast as the overall shadow area cast or, better still, decreasing the filtration of the opposite colour, magenta. The starting filtration was 50 Yellow, 20 Magenta, so another test internegative was exposed at, say, 50 Yellow, 10 Magenta, and another test at 50 Yellow, 5 Magenta, keeping the exposure time slightly less this time, on account of the change in filtration, i.e. say to 9 seconds and 8 seconds, respectively. The contrast of the internegatives could also be corrected at this point. If the test print was too low in contrast, a slight increase in exposure would increase contrast. If too high in contrast, a slight decrease in exposure would lower the contrast. Suppose in this case the contrast was judged to be too low. The test internegatives could be exposed at 14 seconds and 12 seconds, respectively. One of the prints made from the second test internegatives would have shown an improved colour balance in the print. The internegative exposure giving the best print could be used for making internegatives from the vast majority of transparencies. The exposure of the internegative film could be increased or decreased according to the contrast of the transparency. With experience, the shadow to highlight balance of badly exposed transparencies with colour casts could be modified by filtration and exposure changes to give a much improved copy. Very under-exposed transparencies were given one stop more exposure by altering the aperture of the enlarger lens and, correspondingly, very over-exposed transparencies were given one stop less exposure. Similar to duplicating, under exposed transparencies always printed more successfully. During the early 1970s, the exposure range was changed to 1/10 second to 16 seconds. Described above is a method of finding the correct filtration and exposure for any batch of internegative film by trial and error. The Kodak instruction leaflet enclosed in every box of film gave an alternative procedure. This involved taking densitometric readings from grey scales exposed onto internegative film with a densitometer and plotting three separate D log E curves* of the red, green and blue densities of each film layer. (*D log E = density of the actual dye in the film plotted against the logarithm of the exposure) Both methods work, but the one described in the text, above, is possibly easier to carry out, achieves the same result in the end, and doesn't require any knowledge of photographic densitometers (and equipment) or of plotting graphs. |

||

|

Ektacolor

Internegative Film Type 6008 By 1963 Internegative Color Film was available in 80 foot rolls of 35mm size, 100 foot rolls in 46mm size, and 100 foot rolls at 2.423 inches width. It is thought that the films were processed in the special Internegative Replenisher with the addition of Starting Solution from the introduction of the film. The remainder of the process consisted of the normal C-22 chemicals, as used to process Kodacolor and Ektacolor films. The modified process was known as “Process N-31”. In 1970 the film title gained the numbers 6008, and was still being sold in 1977 in the same sizes, plus a 70mm wide roll size of 400 foot length. Vericolor Internegative film, 6011, initially known as SO-406, for processing in the C-41 process, replaced Internegative Color film 6008 in 1978, and the new Internegative 6011 film was processed in the same developer as used for all process C-41 films. Kodak Internegative

35mm film in the UK It was recommended at the time to process the film in C-22 chemicals with a reduction in the normal development time as given for Kodacolor and Ektacolor films. The film was included in the 1962 and 1963 Kodak UK Professional catalogues. There was a printing mistake in both catalogues; purchasers of the film were advised that there was “……………………a modification in first development time.” There was only ever one developer in the C-22 process, and the mistake seems to give the impression that C-22 was a reversal process with a first developer and a colour developer! The mistake was corrected in the Professional catalogue for July 1964. By this time Ektacolor Internegative sheet film was being offered for sale in the 1964 catalogue, having been introduced as a “special order” item in March 1963. Both the 35mm rolls and the sheet film were imported from the USA. It was recommended to process the sheet film in a developer made up from Internegative Replenisher and Internegative Starting solution, and both these chemicals were listed for the first time at the end of the “Colour Materials” section in the July 1964 catalogue. Both the Replenisher and the Starting solution were being imported from the USA. By 1969, Kodak in the UK were advising that the 35mm size film, now known as Internegative Color Film, 6008, should be processed in the Internegative Replenisher plus Starting Solution for best results. The development time was 6 minutes at 75°F, and the rest of the process was identical to Process C-22. In 1978, a C-41 process type of internegative film came onto the market known initially as SO-406, which became Vericolor Internegative Film 6011, replacing the 6008 film. Kodak in the UK published an informative leaflet in January 1979, explaining how to find the correct filtration and exposure times for the new film using a new “Density Difference” method. |

||

| Ektacolor Internegative Film Type 6110 |

|

|

|

In line with Ektacolor Professional Type S and L sheet films, and Ektachrome process E3 sheet films, the packaging of Ektacolor Internegative film was given a new look in 1970. This box (see image alongside) has a “Develop Before” date of January 1971, possibly manufactured about April 1970. Storage instructions were printed in seven languages on the rear label (see picture immediately below). These instructions are exactly the same as on the smaller rear label (see following) of the Internegative film box with a “Develop Before” date of June 1971. |

||

|

||

|

.jpg)

|

|

|

||

|

Vericolor

Internegative Films 6011 and 4112 These films were introduced in the USA in 1979. Both films, 35mm and sheet, were termed 'New' in the 1979-80 Eastman Kodak 'Kodak Photographic Products' catalgue. Vericolor Internegative films were available in the UK by late 1979. Vericolor Internegative films were originally designed for an exposure range of 1/1000 second to 30 seconds with tungsten 3200°K lamps, but during the 1980s the exposure range was changed to 1/10 second to 30 seconds. They were developed in the normal C-41 process with development times and replenishment rates as for Vericolor II camera films. No special developer was needed. The Vericolor Internegative and Print Films were only intended for laboratory use & processing, not for exposure in a camera. |

||||||||||||

|

|

|||||||||||

|

The film could be balanced for exposure and filtration by following the same procedure as for Ektacolor Internegative films (see above). A starting filtration of 30 Yellow, 10 Magenta i.e (30 10 --), was recommended by Kodak,using a trial exposure of about 10 seconds. The Kodak Data sheet E-24 (H) described a technique of balancing Vericolor Internegative films. A densitometer was used to read the lowest and highest densities from a Kodak “Three point transparency guide” exposed on to the internegative film at a trial filtration of 30 Yellow, 10 Magenta with an exposure time of about 10 seconds. A “Three point transparency guide” was a transparent piece of film with three coloured patches, or areas, and three grey density patches, two of which were used to take the red, green and blue density readings. The low density value readings corresponding to the red, green, and blue densities of the film dyes were subtracted from the red, green, and blue high density value readings to give “Density Difference” values. These three "density difference" values were compared to a table in the data sheet of “Density Difference Aims”. From the information in the data sheet the correct filtration for any batch of internegative film could be calculated by altering the trial filtration until the “Density Difference” values of the trial film were within the Density Difference Aims. If the red, green, and blue values from a second trial exposure did not come within the "Density Difference Aims", it was suggested that an internegative was made from a correctly exposed well balanced transparency preferably with a substantial area of grey for colour matching, using the new filtration. The best possible print was made from the processed internegative. The Kodak data sheet included a “Guide for Adjusting Filter Pack” for working out the correct filtration when judging colour casts in the high-light area of the print. Example: If the high-lights were Yellow, the Guide suggested removing 10 Yellow (if a slight cast), or 20 Yellow (if a noticeable cast), from the filtration. The opposite of this would be to add 10 or 20 Blue, but almost all filtrations were in Yellow and Magenta when using Vericolor Internegative films. Another trial internegative was made with the filtration change, and any contrast correction could be made at the same time. Contrast corrections were made exactly as on Ektacolor Internegative film (see above). As long as the final exposure was within the exposure limits of the film, the resulting exposure time and filtration could be used for making internegatives from most transparencies. A good final exposure time to aim for was from 8 to 12 seconds. Vericolor

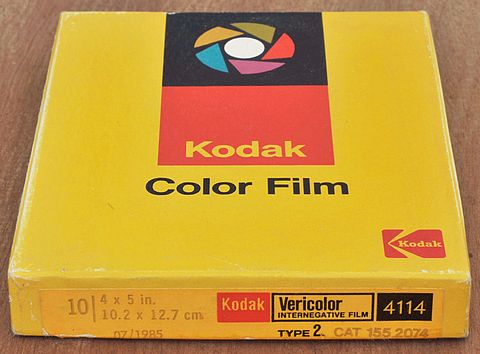

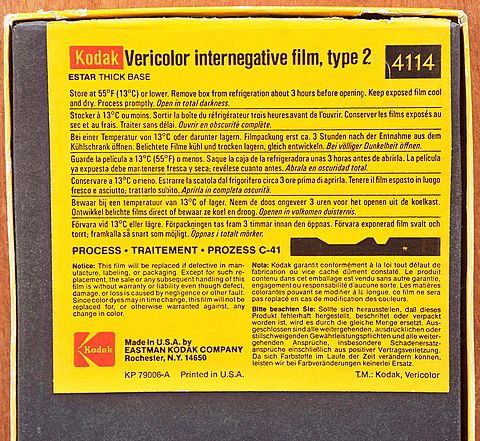

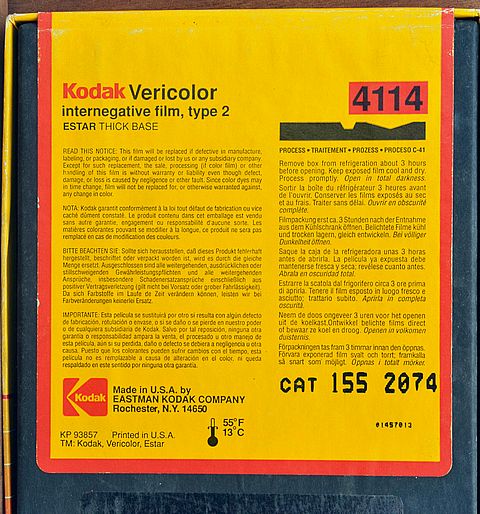

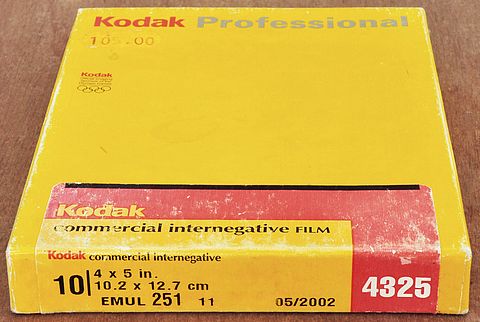

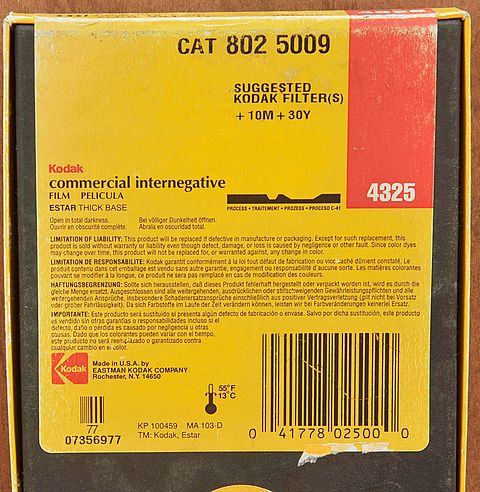

Internegative Film 4114, Type 2 Vericolor Internegative film 4114 Type 2 was not intended as a replacement for Internegative 4112. Kodak “Commercial Internegative Film 4325” replaced Internegative 4114 in 1993 but Internegative 4112 continued to be sold. Vericolor Internegative 4114 Type 2 film was only recommended for making internegatives from transparencies, whereas Ektacolor Internegative film and Vericolor Internegative film 4112 could also be used to copy coloured art works, paintings, or any coloured flat copy. The contrast was changed in the same way as in making internegatives from transparencies. 4114 Type 2 sheet film was obtainable in the sizes: 4 x 5 inches; 5 x 7 inches; 8 x 10 inches. Both Vericolor Internegative films were coated onto a Polyester tear-resistant base, the trade name was “Estar Thick Base”. Kodak Data sheet E–24(T) gives a “Density Difference “ procedure for balancing this Type 2 film similar to the method given above for Vericolor Internegative film 4112. A densitometer had to be used, but readings were taken from Kodak Photographic Step tablets, (Grey Scales, printed onto a strip of film), and the filtration changes could be read from a table in the data sheet showing plus or minus values to alter the Yellow, Magenta and Cyan filtration values. The instructions packed in

each box of film gave a trial filtration for that particular

emulsion number. |

||||||||||||

|

|

|||||||||||

|

|

|||||||||||

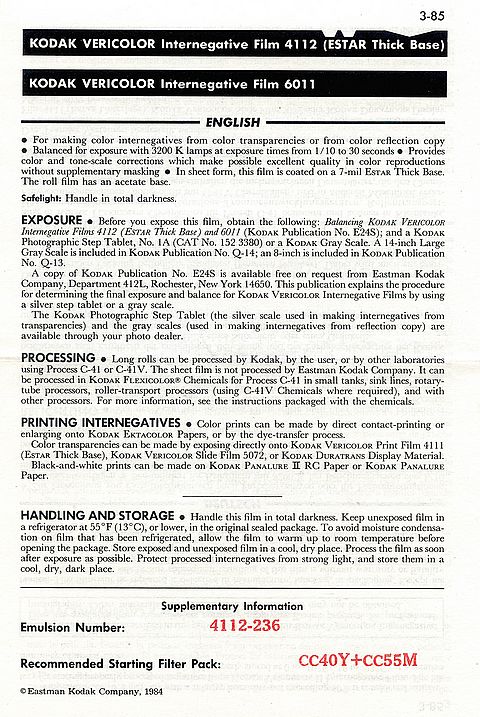

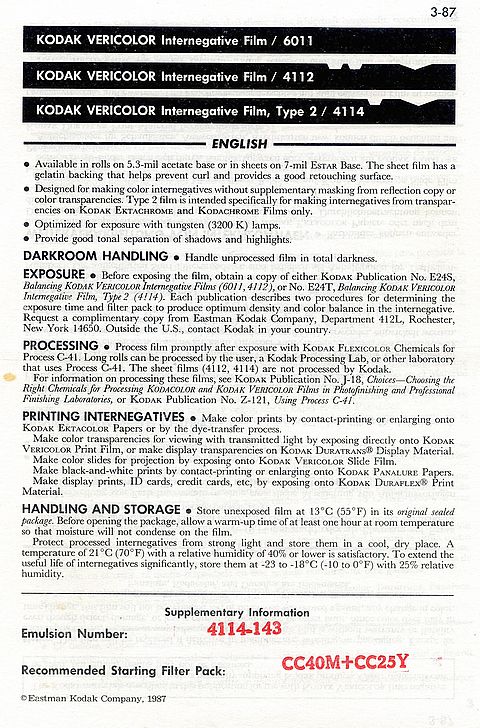

| Processing Vericolor Internegative Films All Vericolor Internegative films were processed in C-41 chemicals, either in “rack and tank” processors or in continuous processing machines. Below are shown two instruction sheets for Vericolor Internegative films 4112, 4114 and the roll film 6011. In both these instruction sheets the user was recommended to obtain a copy of the Kodak publication E24S if using the sheet film 4112 or roll film 6011, or to obtain the Kodak publication E24T if using the sheet film 4114. These publications contained detailed instructions on balancing, with regard to the correct filtration and contrast, when using the films for the first time. At the base of the instruction sheets a “starting filtration” printed in red is given with the emulsion number of the film it refers to printed above. These filtrations could be used to calculate a new filtration when changing from one batch of internegative film to another. |

||||||||||||

|

|

|||||||||||

|

Kodak

Commercial Internegative Films, 4325 Both films were designed for making internegatives from Kodachrome and Ektachrome original transparencies, or for photographing coloured originals on an opaque base, or for copying photographic colour prints. Kodak Vericolor Internegative film, 4112 (see above), was recommended for copying maps and flat artwork.The balancing procedure for both films was described in the Kodak technical data sheets E-225T. Four methods were given for finding the correct filtration and exposure.

The film was intended for use with a 3200°K light source (enlargers with colour heads), at exposure times of 1/10 second to 30 seconds. A first trial exposure would have been about 10 seconds using the suggested filtration printed on the label of the Internegative film box. The Data sheets also gave a starting filtration of 30 Magenta, 30 Yellow. For photographers using the film for the first time, the Data sheets gave details of working out a “Starting Exposure” when using an enlarger to make internegatives. An exposure time of 10 seconds was suggested for the sheet film 4325 when the illumination at base board level without any filtration dialed in the colour head was 32 Lux, or 3 Foot Candles. An exposure for the 35mm film was 1 second with 323 Lux, or 30 Foot Candles. A separate exposure meter could also be used to determine a starting exposure, or the exposure meter in a single lens reflex camera when using the 35 mm film. If the meter was set to 400 ISO (ASA), the correct exposure would be 1/8 second at F5.6. This exposure would apply to the sheet film and the 35mm film. Both types of film were processed in C-41 chemicals, using the same timings and procedure as the camera films. Commercial Internegative Film

4325 was obtainable in sheet format in 1999 as: In 1999, Commercial Internegative Film 5325 was obtainable in 80 foot lengths in 35mm format. By 2003 the length had increased to 100 foot in the same format. These were the last Internegative films made by Kodak. As far as is known the manufacture of both formats ceased in 2006. |

||||||||||||

|

|

|||||||||||

|

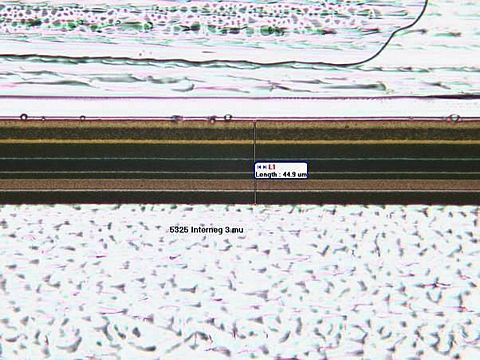

Kodak Internegative 5325 Internegative 5325 was the

35mm equivalent of Internegative 4325 (above). Eastman Kodak

in the USA also sold 46mm, 70mm and a roll film in bulk of 2.42

inches wide. Only the bulk 35mm size was available in the UK

(References: Eastman Kodak Professional catalogue for 1996 and

Kodak UK catalogues of 1999 and 2003). Russ says "Note the unusual emulsion arrangement. The additional magenta layer between TWO cyan emulsions (see processed image, RHS below). This was to provide additional interimage effects to enhance the colour reproduction characteristics of what was a quite complex emulsion of the time." |

||||||||||||

Raw Emulsion |

Processed |

|||||||||||

|

|

||||||||||||

|

As far as is known Ektacolor ID Copy film 5022 was introduced at the end of 1971 in sheet film format and bulk 35mm film. The sheet film and 35mm film were listed in the 1972/73 “Kodak Professional Products” catalogue published in the USA. Sheet film was available in two sizes, 4 x 5 inches and 8 x 10 inches, and 35mm film in 100 foot lengths for darkroom loading, code CID663. The ID Copy film was a colour negative sheet film designed to make copies of flat originals, such as colour charts, advertising posters or architectural drawings. The film was unusual as it could be used to make colour negatives of a continuous tone image together with a line, or type, such as lettering, on the same piece of film. The contrast of the highlights could be changed by increasing or decreasing the exposure time, similar to Ektacolor Internegative film, 6110. Decreasing the exposure gave less contrast, an increase in exposure would give more density. The contrast differences showed more in the highlights i.e the dark areas of the negative. The 35mm film was used in identification cameras to record a portrait image and a line image on the same negative. The 35mm film incorporated the same contrast changing characteristics as the sheet film. The sheet film had a thin acetate base of 5mm, hence the film number beginning with 5. It was balanced for exposure by daylight, or electronic flash at a speed of 80 ISO (ASA), but with suitable filters, could be exposed with other types of illumination at different ISO speeds.

The ISO value for the pulsed xenon relates to the relative speed of Ektacolor ID film to the type of illumination. It was advised not to expose

the film at times less than 1/1000 second or more than 1/10 second.

However, the film could be exposed for times longer than 1/10

second by increasing the exposure given by the exposure meter: It was not recommended to expose for times longer than 10 seconds. Processing If the film was processed in a machine with automatic change over between solutions and washes, the development time was 12 minutes at 75°F. The replenishment rates were higher compared to other Ektacolor films. Ektacolor ID Copy film 5022 was replaced by Vericolor ID Copy film 5024 for Process C-41 in 1977 but only in the 35mm format, included in the Eastman Kodak publication “Kodak Color Films”, E-77, published in December 1977. The 35mm Vericolor ID film was available in three specification numbers as listed in the Eastman Kodak “Kodak Photographic Products” catalogue for 1979-80. As far as can be found, Vericolor ID Copy film in sheet film format was not obtainable until the late 1980s. |

||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Introduction “Duplicate” transparencies of any size could be made on Ektacolor Print Film. Any number of duplicates could be obtained and the results on Print Film were far better than trying to duplicate an original Ektachrome or Kodachrome transparency onto Ektachrome Type B sheet film. No sheet films specifically for duplicating colour transparencies were manufactured by Eastman Kodak until 1966 (see Ektachrome Duplicating Films). The film was intended to be exposed in enlargers, notably the “Kodak Auto-Focus Enlarger, model E”, a Kodak enlarger listed for sale in “Kodak, Products for the Professional”, an Eastman Kodak catalogue dating from 1949. The Data sheet for the film advised that a heat absorbing glass and a UV filter should be fitted to any enlarger used for exposing Ektacolor Print Film. The film was balanced for a colour temperature of approximately 3200°K. Colour balance was varied by means of Kodak Color Compensating Filters (CC), or the later Kodak Color Printing Filters (CP), or a colour head fitted to a black and white enlarger, such as an Agfacolor head, or a purpose built colour enlarger (Agfa Varioscop 60). |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Chronology of Ektacolor Print Film

The Introduction dates given in the second column apply to Ektacolor Print Film sold in the USA. Similar film was likely introduced a year later in the UK. Notes:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

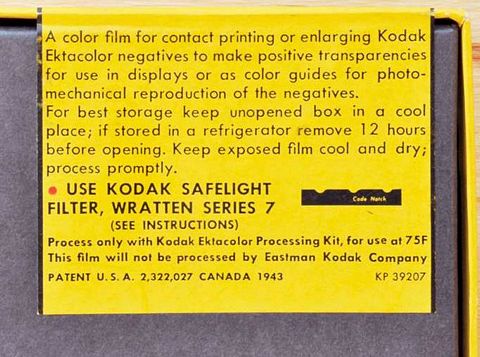

Exposure

and Processing of Early Print Film - 6105 thr' 6108 An exposure time of 10 to 20 seconds was recommended as a “starting” exposure time. As each batch of Print Film varied in speed, the supplementary data sheets also suggested a “lens opening adjustment” for altering the exposure time when changing from one batch of film to another. This was noted on the sheet as “Decrease Exp. ½ stop”, or “Increase Exp. 1&2/3 stop”. The filtrations given were generally used to calculate the new filtration when changing between batches of Print Film rather than using the filtration figures as a “starting filtration”. Kodak had already allocated the Type Number 6106 to Ektacolor Type L film (in 1958) and 6107 to its Commercial Ortho black and white film. Hence, the next Print Film became 6108, introduced in 1960. The recommended “starting exposure” time had increased to 20 to 40 seconds. About the same time the Wratten Series 7 safelight filter recommendation was changed to a Wratten Series 10, or 10H (for the UK) filter. This was “dark amber”, or a very dark orange colour. The film could be handled under this filter for about 5 minutes at a distance of about 4 feet from the safelight. In the mid-1970s, the minimum exposure time recommended for Ektacolor Print Film 4109 had been reduced to 1 second. The exposure time range was now 1 second to 120 seconds. Processing It was possible that the C-22 development time for Print Film prior to 1960 was 14 minutes at 75°F. The instruction sheets after this date (Type 6108) recommend 12 minutes at 75°F. The times in the rest of the solutions and washes were identical to the process times for Ektacolor and Kodacolor films. When processing in the “Ektacolor Process Kits”, Ektacolor Print Film and Ektacolor Type B film could be processed together, but the first three steps had to be carried out in total darkness, not under the Wratten Series 7 safelight! |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Ektacolor

Print Film ~ Later Type - 6109 It was recommended that the film should be handled in total darkness, but a safelight with a 15 watt bulb (English instructions state 25 watt bulb) fitted with a Kodak Wratten Series 10 filter could be used at a distance of 4 feet as long as the film was not exposed to the direct light of the lamp for longer than 30 seconds. In the UK instruction sheets, the safelight filter was known as “Wratten 10H” (dark amber), but the filter was identical to the Wratten Series 10. The “No.13” Kodak Safelight filter (amber), introduced in 1973 and intended for use with, at that time, Ektacolor 30RC and 37RC papers and later colour printing papers, was not safe to use with Ektacolor Print Film. The sensitivity of the 6109 film was approximately equal to Ektacolor Paper, although Ektacolor Paper could be handled under the same safelight for a much longer time, about 4 minutes. Exposure Filtrations for Ektacolor Print Film were similar to those on Ektacolor papers, but most negatives required a higher magenta filtration compared to the colour papers. If a certain negative had made a successful print on Ektacolor paper, its filtration would make a good starting filtration for a transparency on Ektacolor Print Film, with a “stepped test” exposure on the film. The film was generally about half the speed of the printing paper. Test transparencies appeared much too reddish~magenta whilst wet, and colour balance and exposure could only be successfully assessed when the film was completely dry. The film was not completely “clear”; it had a slight opaque appearance compared to an Ektachrome transparency. This created a “diffuser” effect when viewing a Print Film transparency. In 1970, Michael Talbert made some 2¼ inches square transparencies by contact onto Print Film. The transparencies were intended for projection but, when projected onto a white wall, they gave an odd, diffuse, unsharp image compared to High Speed Ektachrome film transparencies. He came to the conclusion that transparencies made in this way were not suitable for projection; Ektacolor Print Film transparencies were only acceptable for display purposes, where they could be illuminated from behind. Later, when making some 11 inch x 14 inch Ektacolor Print Film transparencies on a Beseler enlarger using Kodak Colour Printing (CP) filters inserted into the filter draw, he found that when he changed the exposure time, the colour of the Print Film also changed. To alleviate this problem, he altered the exposure by the lens aperture when the test prints were very close to the correct colour i.e. keeping the exposure time constant. He used this method of altering the exposure because of his lack of experience of making Print Film transparencies at that time (1971). But, with more experience, he became adept at filtering out the slight change in colour when changing exposure times. Ektacolor Print Film emulsions were coated onto a thick, acetate base, approximately equal to the thickness of a sheet of Kodak black and white sheet film before sheet films were coated onto an “Estar” polyester thick base. In 1971, the base of the 6109 Print Film was changed to a similar (Estar thickness) base, which was thinner than the acetate base. It then became 4109 Print Film. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Ektacolor Print Film - 4109 | |||||||||||||||||||||||||||||||||||||||||||||||||

.jpg)

|

.jpg) |

||||||||||||||||||||||||||||||||||||||||||||||||

| Kodak Vericolor Print Film - 4111 Kodak Vericolor Print Film 4111 (sheet) was designed for making large display transparencies from colour negatives and internegatives. It had a thick base and a matt surface to facilitate retouching and was available in sheets and wide rolls. It replaced Kodak Ektacolor Print Film. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Kodak

Duratrans Display Film - 4022 An early name for the EP-2

material was “Kodak Ektacolor 74 Duratrans Print Material”,

as printed in the “Kodak Color Films” book, dated September

1980. The description given is: The film had a “built in” white pigmented coating on the support, which acted as a diffuser. The film was said to have the same exposure characteristics as Kodak Ektacolor 78 paper. This is the processing sequence for Duratrans Display Film 4022 in Process EP-2 chemicals using small, manual tube processors, tanks, dishes and the Kodak rapid processors.

Notes:

It could be processed in Ektaprint 2 chemicals with an adjustment to replenishment rates and an increased development time compared to Ektacolor papers of 6 minutes. Because of the increased thickness of the base of the Display film compared to Ektacolor papers, longer drying times were necessary. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Chronology of Kodak Duraflex Print Material 4023

and Duratrans Display Material 4022

"Day-Night”

Prints and Dye Transfer Film. Dye Transfer film was a non light sensitive translucent white film with a pre-mordanted emulsion coated on one side to accept Dye Transfer Cyan, Magenta, and Yellow dyes. The mordant held the dyes in place in the film emulsion. The film could be viewed by reflected light like an ordinary colour print (Day), or a combination of reflected and transmitted light if lit from behind like a colour transparency (Night). Dye Transfer film was introduced in 1965-66, first known as SO-351 film, later as 'Dye Transfer Film 4151', Estar base, obtainable in sheets and rolls. The sheet sizes were discontinued in 1971 but a roll size of 43 inches wide by 100 foot long was available up to the late 1980s. As far as is known, the film was only made in the USA and was only used by laboratories making professional Dye Transfer prints e.g John Piercy Ltd, Bryanston Street, London was one such lab. Dye Transfer paper was manufactured in the USA and the UK and was listed in USA and UK Kodak catalogues. None of the UK professional catalogues (in the author's possession) list Dye Transfer film, but it could be imported. Eastman Kodak ceased making materials for their Dye Transfer process in 1994. The Dye Transfer process was complicated. The dyes in a Dye Transfer print were put there by three "relief" images, called matrices, one for cyan dye, one for magenta, one for yellow. The picture was "built up" with dyes. The matrix film had a relief positive image so its shadow areas had more density and picked up more dye than the highlights with less density. The three matrices were generally made from a colour transparency. The problem was that a colour transparency has a much greater density range than can ever be reproduced on a paper print, so the transparency has to be masked before the matrices are made, like making a duplicate transparency onto camera film instead of using the much lower contrast duplicating film. The work involved: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Duratrans RA Display Material - 4007 Duratrans RA Display Material was designed for producing backlit display transparencies intended for use on illuminators without diffusers. This material was almost identical to Kodak Duratrans Display Material 4022 for processing in EP-2. The emulsions were coated onto a 7mm “Estar” thick base with a white pigmented coating acting as a “built-in” diffuser and the material could be processed in almost half the time of the older EP-2 material. Duratrans Display Material was very similar to Vericolor Print Film, 4111. Introduced around 1990, in 1991 it was obtainable in the USA in sizes from 8 x 10 inch sheets to rolls of 74 inches wide and 100 foot long. RA-4 processing procedures for the 4007 (and Duraclear 4004 film, see below) vary slightly, depending on the type of processor, or the method of processing. As far as is known, these procedures date from 1990 when the Duratrans (and Duraclear) films became available. Processing in dishes, small rotary tube and drum processors such as Kodak Printank and JOBO plus others. This sequence can also be used with the Kodak Rapid Processors H11-L, 16 K and the model 30A.

Notes:

Processing in roller transport machines.

Notes:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Kodak Duraflex Print Material - 4023 Introduced as Kodak Ektacolor ID Print Material as long ago as 1975, this printing material was for making prints from colour negatives to produce identification cards, postcards, or any other items that required a lot of handling or heavy use. The light sensitive emulsions were coated onto a white pigmented 7 mm thick Estar base film with a glossy (F) surface. The emulsions coated onto the 1975 version were similar to the emulsions used on Ektacolor 37RC paper. The material could be laminated on both sides for extra protection against moisture or very heavy use. Originally processed in Ektaprint 3 chemicals, using the same procedure as when processing Ektacolor 37RC paper, by 1980 the Ektaprint 2 process became the standard process. Duraflex Print Material, 4023 was replaced by Duraflex RA Print Material, 4008 for RA-4 processing about 1990. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Introduction

~ Type 5381, 5382 and (Later) Type 5028 Although the film was first introduced in 1958, Kodak had manufactured “colour print films” for the motion picture industry for many years previously. Eastmancolor Print Film Type 5381 and 5382, used for making cinema projection 'prints' from Eastmancolor negative 35mm cine film stock, had been marketed as long ago as 1950. In the late 1950s, Kodak in the USA were offering to make Kodacolor transparencies from Kodacolor negatives in standard sizes, mainly 35mm, onto a film very similar to (what became) Ektacolor Slide Film. In the UK, Ektacolor Slide Film was first listed for sale in the Kodak Professional catalogue for 1964-65, obtainable in 100 foot lengths of 35mm film. It sold at a slightly lower price than the equivalent length of Ektacolor Professional film, Type S. The base thickness was about equal to 35mm colour negative film, much thinner than Ektacolor Print Film. The film could be exposed by contact printing, or by projection printing in enlargers, or in various printers such as the “Bowens Illumitran”, Homrich internegative and duplicating printer, plus others. Kodak recommended exposure times of ¼ second to 8 seconds in tungsten light. The film was also available to special order in large sheet film sizes and wide rolls, mainly for colour printing laboratories. The author remembers exposing the film at much longer times than 8 seconds when making 8 x 10 inch transparencies on the sheet film version. The film was processed in Process C-22 chemicals, with a development time of 17 minutes, the remaining solution times were exactly the same as when processing Kodacolor roll film or Ektacolor Professional sheet film. Ektacolor Slide Film 5028 first gets a mention in the Kodak “Trade Circular” for December 1963 as a new product in the UK “Kodak Ektacolor Slide Film will be available in 35mm x 100 ft. rolls, at a cost of £12 3s 10d.” The film was likely to have been obtainable in early 1964. By the end of the 1960s it had gained the number 5028, and in the early 1970s it could be additionally obtained in 8 x 10 inch boxes of 10 sheets of film. It was also available in boxes of 15 x 12 inch sheets and wide rolls to special order. These sheet films were identical to the 35mm film. Exposure The boxes of Slide Film had no instruction sheets or data sheets enclosed with the film. Having made 10inch x 8 inch transparencies on this film from Ektacolor sheet film negatives on a De Vere enlarger fitted with an Agfacolor head, the author can say that the filtrations were similar to Ektacolor Print Film. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

To the right is shown a very early package of Kodak Ektacolor Slide Film containing a tin of 100 feet of 35mm size film. The emulsion number is 5025 – 7 – 1, making it the seventh (or eighth if starting at 0) emulsion coated. The identifier 'SP663' in the lower image refers to the 'core' onto which the film was wound. With a “Develop Before” date of July 1959 it was likely the film was first introduced in 1958. The film may have been very similar to 35mm Eastman Kodak motion picture films, Type 5381 and 5382. These two films were used for printing projection copies from Eastmancolor 35mm motion picture colour negative films. Ektacolor Slide film was introduced too late to be included in the Eastman Kodak publication “Printing Color Negatives” Data book, first edition, E-66, published in July 1958. Also the film was not listed in the Eastman Kodak “Photographic Materials” catalogue for January 1961, or in the price list corresponding to the catalogue. It is possible, at that early stage, the film could only be obtained by Special Order. In the second edition of the E-66 publication, published in July 1961, Ektacolor Slide film is described as being very similar to Ektacolor Print film, No. 6108. Slide film was exposed in the same way and could be processed in Kodak Color Film chemicals for Process C-22. Later the number of the film was changed to 5028, possibly in 1963 when a faster version of Ektacolor Print film, No. 6109 was first introduced. Certainly by the late 1960s, the Slide Film was obtainable by special order in sheet and wide roll sizes as Ektacolor Slide Film 5028, mainly being used in colour laboratories for producing large display transparencies. These images are by courtesy of, and agreement with, US eBay retailer 'red-books-and-collectibles'. |

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Kodak

Vericolor Slide Films for Process C-41 (5072 and SO-279) Available in 35mm widths in three specifications and a 46mm width.

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

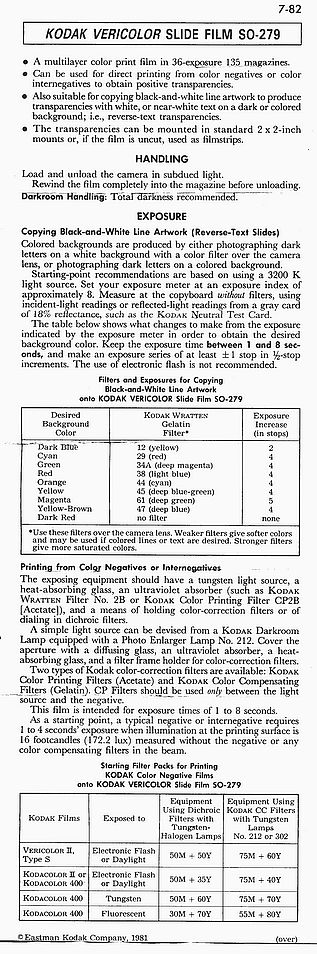

By 1981, the film was being packed into cassettes of 36 exposures for loading into 35mm cameras, sold as “Vericolor Slide Film, SO-279”. Vericolor Slide film was designed for printing using 3200°K lamps at exposure times from ¼ second to 8 seconds. The data sheets gave starting filtrations for Vericolor II Professional, Kodacolor II, and Kodacolor 400 films which had been exposed to daylight, electronic flash, or fluorescent lighting. Filtrations for the film generally contained a higher magenta value than yellow. The acetate clear base of the film was similar to Ektacolor Slide film, and darkroom handling was identical. It was recommended to handle the film in total darkness, but it could be exposed to a Kodak No.10 or 10H safelight filter for no longer than 30 seconds. The Kodak No.13 safelight filter was too bright for the film and would fog it. In the UK, Kodak Limited London published a leaflet in January 1979 describing the then new Vericolor Slide film – “Kodak Laboratory Films for Process C-41”. Vericolor Slide film 5072 was made available in the UK from 1979 in 35mm and 46mm widths in 100 foot lengths. The specification number for the 35mm format was not given in the Kodak UK January 1981 price list, but it is thought that the number was VS 663. As far as is known, Kodak UK never marketed the film in 35mm 36 exposure cassettes (i.e. SO-279). SO-279 was processed in exactly the same way as Vericolor Slide film 5072. |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

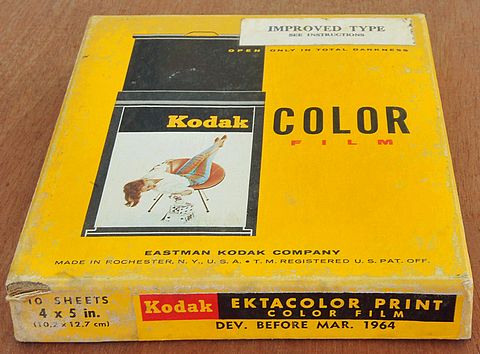

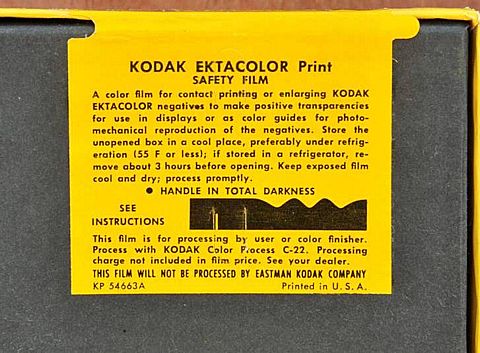

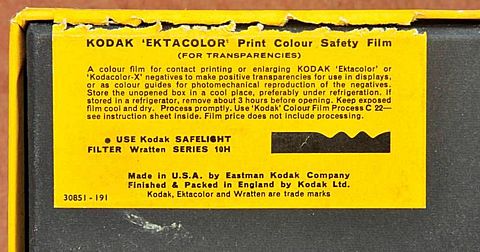

Alongside are the two pages of an instruction sheet for the use of Vericolor Slide Film SO-279 dated July 1982. At this time 35mm cassettes of Vericolor Slide film were not obtainable in the UK and 35mm film was only available in bulk lengths of 100 feet as Vericolor Slide Film 5072. Below is shown a 36 exposure carton of Vericolor Slide film SO-279 for making colour transparencies from colour negatives. The film was also suitable for copying black and white line artwork to produce transparencies with white or near white text on a dark or coloured background. The film instructions included in the film carton (as shown left) gave suggestions on the correct Kodak Wratten filter to use for obtaining coloured backgrounds. |

|

.jpg) This film had a “Develop Before” date of October 1988. The film speed was about 8 ISO (ASA). |

.jpg) |

|

|

Kodak

Duraclear RA Display Material 4004 In early 1992, the film was available for sale in the USA in sheet sizes from 8 x 10 inches to 30 x 40 inches, and roll sizes from 10 inches wide to 6 feet wide. The box shown below is believed to have had a "Dev. Before" date of October 1994. The RA-4 processing procedure for Duraclear Display Material 4040 was the same as is shown (above) for Duratrans RA Display Material - 4007 By 2001, Duraclear RA Display Material had been replaced by “Professional Endura Clear Optical Display Material”. |

|

|

|

|

|

|

|

|

|

|

|

Ektacolor Print and Slide films were processed in C-22 chemicals, but the developing times were different to the camera sheet, roll, and 35mm films. Print Film required 12 minutes development and Slide Film required 17 minutes development at 75°F. These times date from 1960 for Print Film and 1969 for Slide Film but pre-1960 Print Film required a development time of 14 minutes. Later processing sequences, dating from the mid-1970s, suggested development times of 11 minutes for Print Film and 16 minutes for Slide Film. The remaining steps for the sequence were identical to the sequence for camera films. |

|

|

Ektacolor

Print Film Additive (from 1964) Ektacolor Print Film Additive was made available in the UK from August 1964 in four US fluid ounce bottles priced at 13shillings (65p) per bottle. By April 1965 the price had dropped to 9shillings and 6oldpence (about 48p) per bottle. In a replenished C-22 process, when processing Ektacolor Print or Slide film, Ektacolor Print Film Additive was mixed with the C-22 developer. The purpose of the Additive was to compensate for the effect of the Print Film or Slide Film on the chemical balance of the developer. The Additive was packaged as a liquid in 4 US fluid ounce bottles. It was diluted to a stock solution which was mixed with the C-22 developer at the rate of 1% of the total volume of C-22 developer replenisher being used for each batch of Print or Slide Film processed. This was equivalent to 3¼ ccs for every square foot of film processed, or approximately 3¼ ccs for every two sheets of 8 inch x 10 inch Print Film. As an example: Add Replenisher

plus Additive to the developer after processing each batch of

Print Film. The replenishment rate was 325ccs of developer replenisher

to be added to the developer for each 1 square foot of Film

processed. Hence, having processed 4 off 8 inch x 10 inch

sheets (or 16 off 4 inch x 5 inch sheets): In an unreplenished C-22 process, such as when processing sheets of Print Film in dishes, the 'Unit 1' 2litre size C-22 Process component containing the Developer and Stop Bath (see picture of box above), would process at least 12 sheets of 8 inch x 10 inch Ektacolor Sheet Film (6,450 square cms) before exhaustion, but only 2½ sheets of the equivalent area of Print Film before exhaustion (1,290 square cms). The rest of the solutions in the 2litre kit, i.e. the 'Unit 2', would process at least 24 sheets of 8 inch x 10 inch Ektacolor Films, including Ektacolor Print Film (12,900 square cms). For processing the Print and Slide Film on a regular basis, Kodak recommended a replenished C-22 system for best results. It was not advisable to develop the films giving “time compensation” with the development time, as used with the smaller C-22 kits when processing 35mm and roll size Kodacolor (X) films. Nevertheless, an article on the processing of Ektacolor Print Film by Ernest Gehret, published in the British Journal of Photography Almanac of 1960 (and in later Almanacs/ Annuals), gave time increases with increasing exhaustion of the C-22 Developer for up to 12 sheets of 4 inch x 5 inch Print Film processed in 1litre of developer. Gehret suggested times of development of 14 minutes for the first three sheets, to 16½ minutes for the last three sheets. The time increases for development were for the 6108 type of Ektacolor Print Film where the Additive was not required. Ektacolor

Print Film Stabilizer Its use was recommended for all display transparencies where it gave a significant improvement in dye stability of the yellow and magenta dyes of Ektacolor Print Film. The Stabilizer treatment replaced the one minute 'Photo Flo' rinse step at the end of the process, and transparencies were given 1 minute treatment time at 73–77°F before drying. The concentrate was diluted with six parts water to make a stock replenisher solution, and four parts of the stock solution were further diluted with one part water to make the working solution. The replenishment rate was 80 ccs of replenisher to 1 square foot of Print Film processed. In 1978, Ektacolor Print and Slide Films were replaced by Vericolor Print Film 4111, and Vericolor Slide Film 5072, designed for the C-41 Process. The first “Print Film” for processing in EP-2 chemicals was Kodak Duratrans Display film SO-245, introduced in 1980, later becoming Duratrans Display film, 4022. A later version was processed in RA-4 chemistry. Kodak Duraclear RA Display Material 4004 was introduced about 1990. The material was processed in Kodak Ektacolor RA chemicals, Process RA-4, with a dry to dry time of only 10 minutes. |

|

|

Processing

Ektacolor Print Film 6109 and 4109 in the Kodak 30A Rapid Processor Seemingly, the total processing time, working at a temperature of 75ºF, was 15 minutes. The large difference in the total time of 15 minutes compared to the normal processing time of 51 minutes at the same temperature was made possible by using the replenisher solutions instead of the working solutions, and by continuously agitating the Print Film in each solution. In general, replenisher solutions are two thirds stronger than the working solutions. In addition, Ektacolor Print Film Stabilizer was used as a final bath, instead of the usual Photo Flo rinse, which gave more stability to the yellow and magenta dyes. In the UK, in 1973, the Kodak Rapid Processor Model 30A was supplied with one 3040A processing tube (drum), one 2024A processing tube (drum), and one processing tube adapter for prints smaller than 20inches x 24inches. A timing disc was also supplied for timing the processing sequence when processing Ektacolor 37RC paper. The Eastman Kodak catalog for the USA gives more information about the 30A processor. There were 10 solution containers, a self contained 100ºF thermostatically controlled water bath, and two timing discs for Ektacolor 37RC paper, one for 50Hz power supply, and one for 60Hz power supply, plus the two tubes (drums) and adapter. The 100ºF water bath could not be used when processing Ektacolor Print Film, and the operator had to provide his own supply of thermostatically controlled water at 75ºF. There were no timing discs for Ektacolor Print Film and the operator had to time each solution and wash with his own timing device. When processing the Print Film, five additional solution containers were required for use with the 3040A tube (drum) and two additional containers with the 2024A tube (drum). It is possible that some or all of these containers were used for the final wash. In the description of the Kodak Rapid Processor Model 30A in the 1973 Kodak Professional Catalogue for the UK, there is no mention that the machines could also process Ektacolor Print Film. By 1980 the 30A had been withdrawn from the catalogue and was no longer for sale in the UK. |

|

|

|

|

|

|

|

.jpg)

.jpg)

.jpg)

.jpg)